Vibration stirring device capable of improving distribution uniformity of cement particles

A particle distribution and vibration stirring technology, which is used in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as uneven distribution, cement agglomeration, and mixture segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and embodiments.

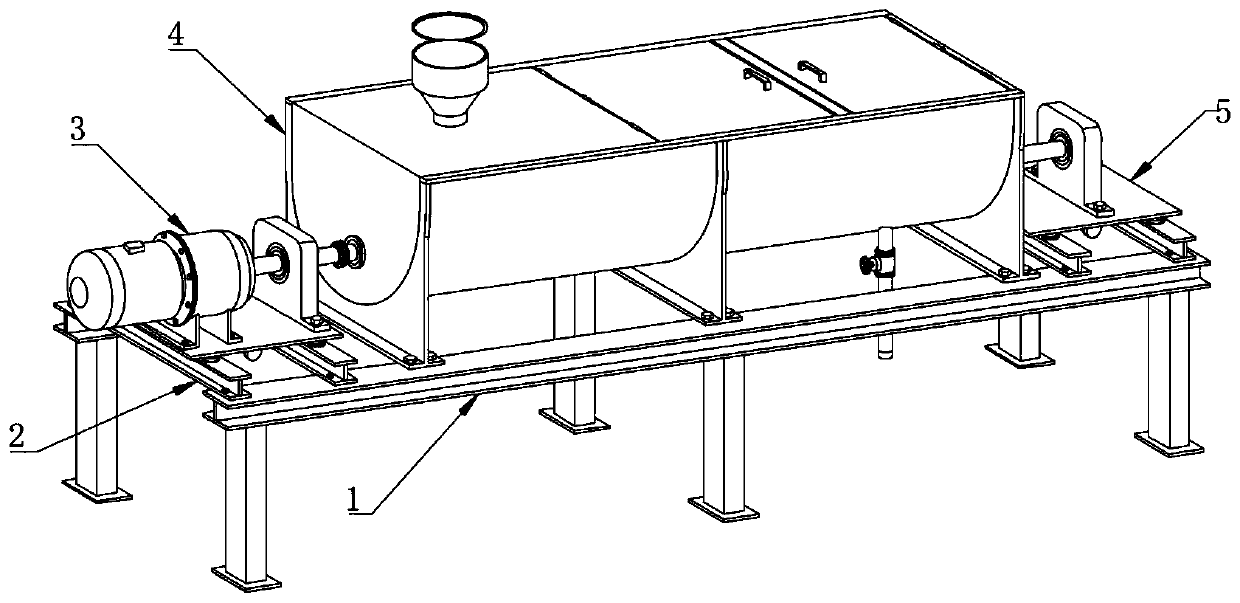

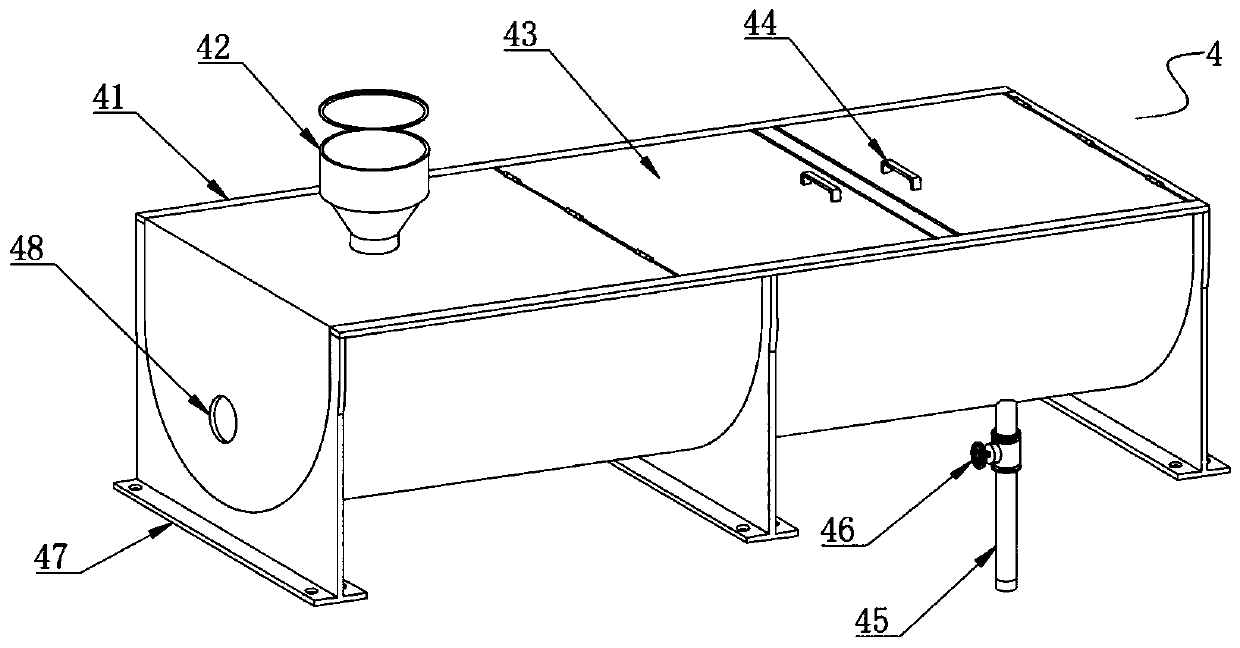

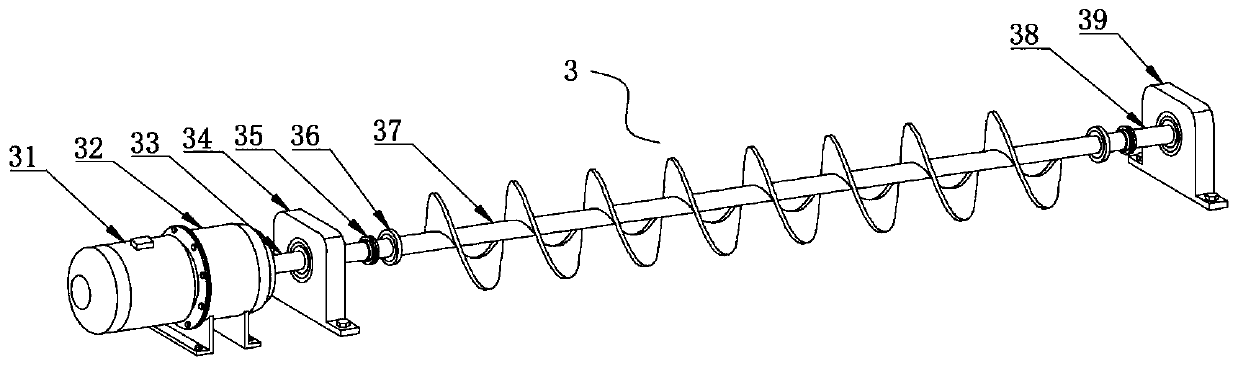

[0025] Such as Figure 1 to Figure 3 As shown, a vibrating stirring device that can improve the uniformity of cement particle distribution includes 4 silos, a first vibrating platform 2 and a second vibrating platform 5 located at both ends of the 4 silos, and a stirring mechanism 3, and the upper part of the silo 4 It is provided with a feed port 42, a discharge port 45 with a valve 46 at the lower part, and shaft holes 48 at both ends. The stirring mechanism 3 includes a stirring shaft 37, a stirring motor 31, a reducer 32, a first bearing seat 34 and In the second bearing seat 39, the stirring shaft 37 is arranged longitudinally in the silo 4 with stirring blades. The two ends of the stirring shaft 37 are matched with the elastic shaft seal 36 to penetrate the corresponding shaft hole 48, and respectively connect with the shaft through the coupling 35. The first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com