Discrete resin bonding and forming protective material and preparation method thereof

A technology of resin bonding and protective materials, which is applied in the field of functional protective materials and its manufacturing process, can solve the problems of poor fabric softness and air permeability, complex production process, and low production efficiency, and achieve clear gaps, soft air permeability, The effect of reducing the generation of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a method for preparing a discrete resin-bonded protective material, comprising the following steps:

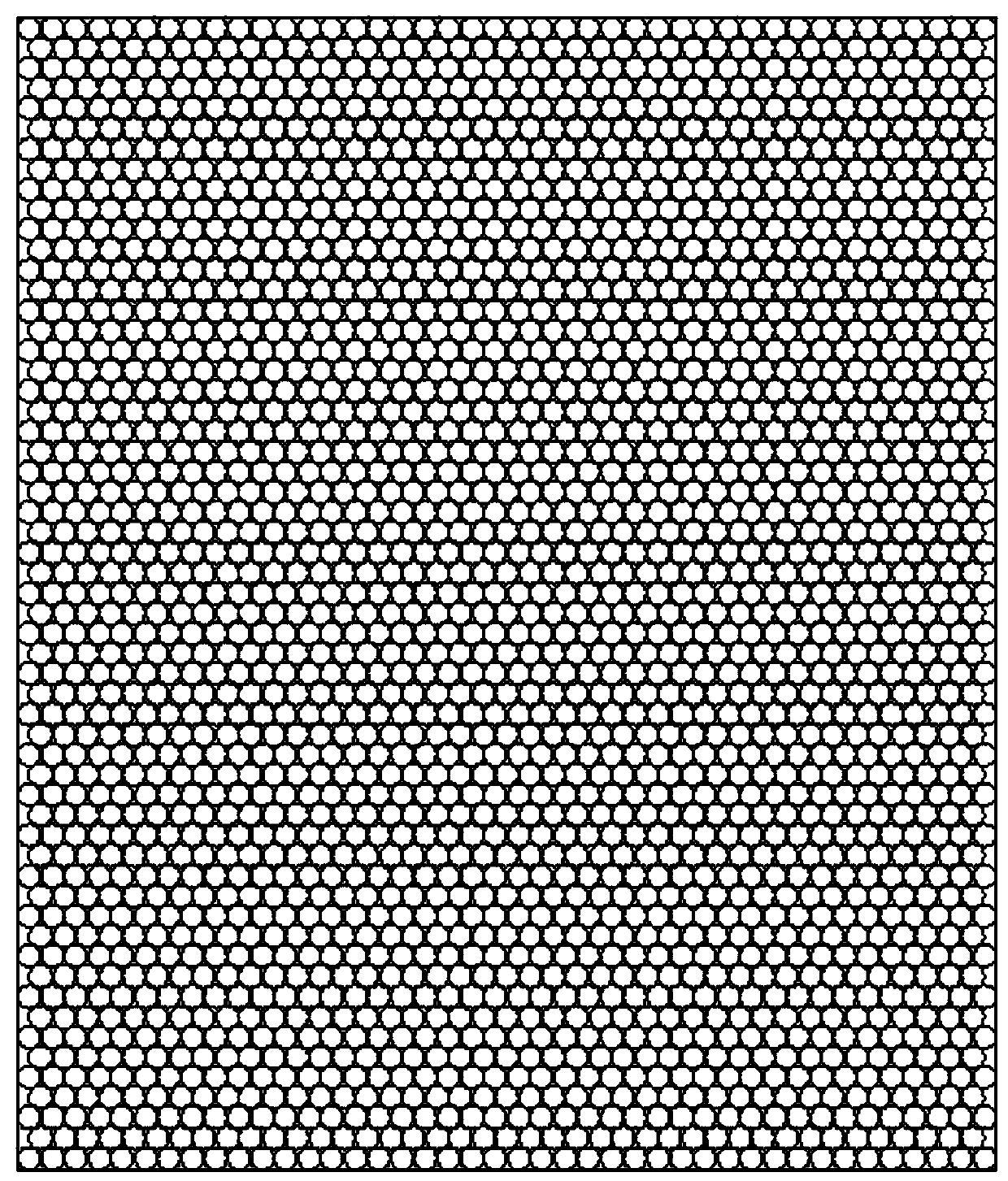

[0031] S1: Prepare a flat plate forming mold with a thickness of 3-100mm, a length of 100-2000mm, and a width of 100-2000mm. Many small holes are evenly distributed on the flat mold. The small holes can be arranged to form various patterns. The gap between the small holes The size of the hole is between 0.1-5mm, the hole depth is 0.6-5mm, the size of the hole is the size of the horizontal plane, and the distance between any two points is 1-20mm. The resin particles are evenly distributed in the small holes of the flat mold, so that each small hole is filled. filled with resin particles;

[0032] The patterns formed by the small holes are triangles, quadrilaterals, pentagons, polygons, irregular patterns or the shape of the sleeves of clothes, the shape of the front piece, the shape of the back piece or the shape of the palm of the glove; i...

Embodiment 1

[0043] Preparation of a discrete resin-bonded protective material:

[0044] The die hole on the flat plate forming mold is designed to be the shape of the front piece of clothes. The thickness of the flat die is 10mm, the length and width are 70cm×60cm, the die hole size on the die is 15mm, the hole depth is 2mm, and the gap between the die holes is 0.5 mm.

[0045] First, evenly distribute circular nylon glass fiber particles with a diameter of 14.5mm in the die holes of the flat mold, so that each hole is filled with particles. Secondly, put the flat mold filled with nylon glass fiber particles on the flipping device, and then place a metal frame of 80cm×70cm on the mold, and transfer the resin particles on the mold to the metal mesh of the metal frame by controlling the flipping device bottom surface. Again, spray polyurethane liquid adhesive evenly on the resin particles in the metal frame, the excess adhesive flows down from the mesh holes of the metal mesh on the botto...

Embodiment 2

[0048] Preparation of a discrete resin-bonded protective material:

[0049] The die hole on the flat plate forming mold is designed to be the shape of the palm surface and the palm back of the glove. The thickness of the flat die is 10mm, and the length and width are 50cm×40cm. The die hole size on the mold is 4mm, and the hole depth is 0.8mm. The gap is 0.2mm.

[0050] First, evenly distribute circular polycarbonate particles with a diameter of 3 mm in the die holes of the flat mold, so that each hole is filled with polycarbonate particles. Secondly, place the flat mold filled with particles on the turning device, and then place a 60cm×50cm metal frame on the mold, and transfer the resin particles on the mold to the metal mesh bottom surface of the metal frame by controlling the turning device. Again, spray polyester-type hot melt adhesive powder evenly on the resin particles above the metal frame, and the excess hot melt adhesive powder flows down from the mesh holes of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com