Automatic intelligent detection and packaging production line equipment for memory stick packaging boxes

A technology of intelligent detection and packaging, applied in the direction of automatic packaging control, packaging, packaging machines, etc., can solve the problems of low efficiency of labeling, detection and packaging, costing enterprise labor costs, and spending a lot of time, so as to save labor costs , improve work efficiency, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] First of all, let me explain the original design intention of the present invention. In the current production and packaging of memory sticks, memory sticks and their packaging boxes need appearance inspection and labeling, and foam cotton needs to be placed in the packaging box. There are many processes in the middle, and the cost will increase if manpower is used. , and the error rate is also high, it is best to design an automatic intelligent packaging equipment to solve the above problems, for this reason, we have designed an automatic intelligent detection and packaging production line equipment for memory stick packaging boxes.

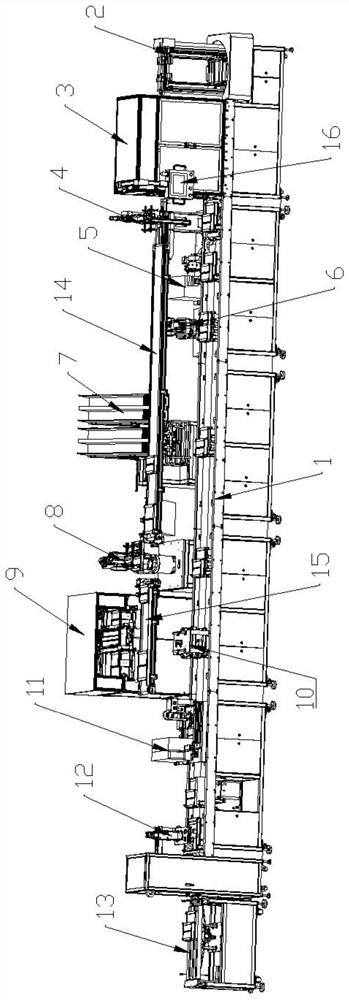

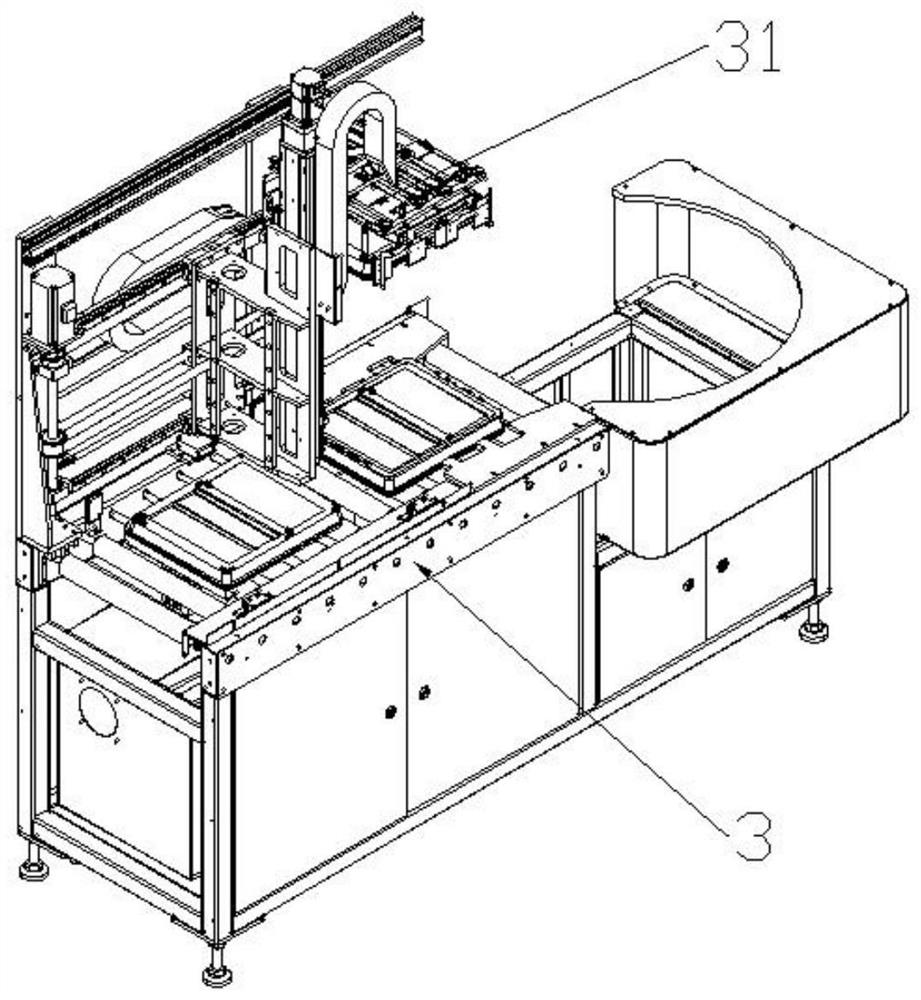

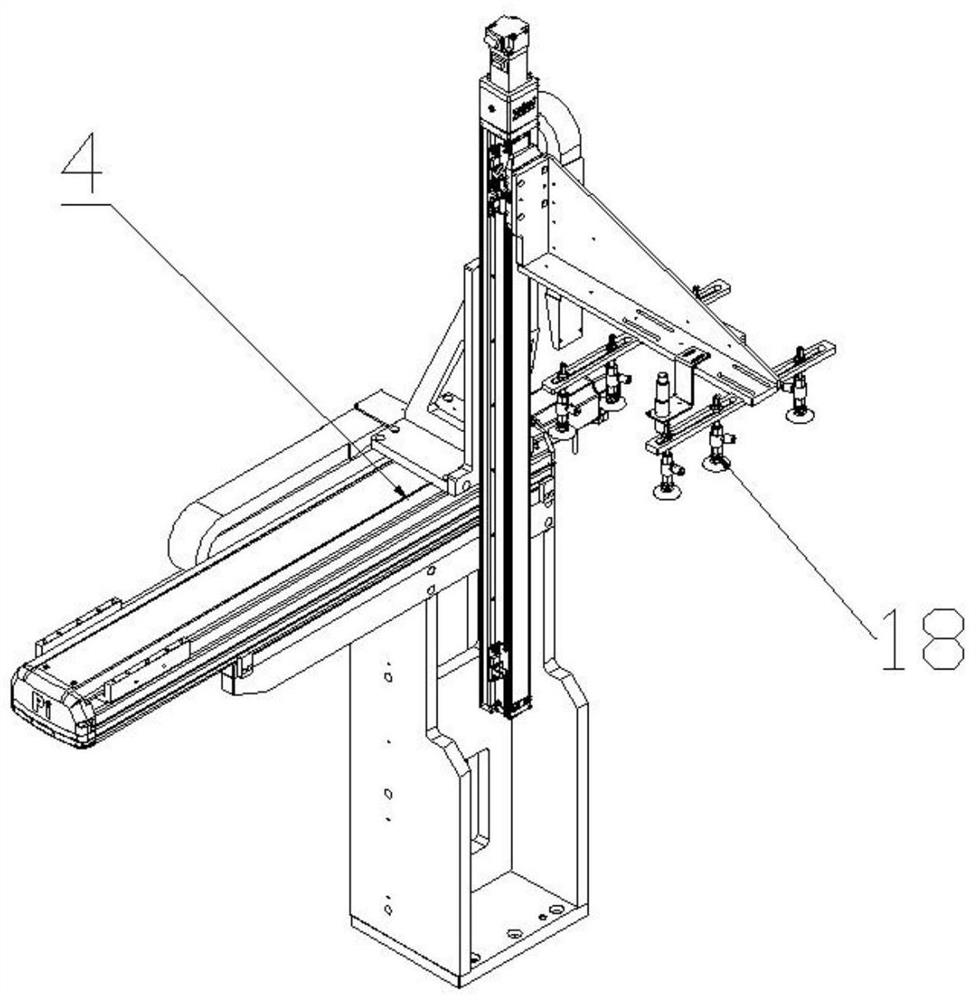

[0032] In order to facilitate those skilled in the art to make this technical solution more clear, the following will be combined with the attached Figure 1-12 Illustrate the concrete structure and principle of each mechanism of the present invention: first generally explain the concrete mechanism of the present invention, as figure 1 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com