Remote monitoring control system for swill three-phase separation and monitoring method thereof

A three-phase separation, remote monitoring technology, applied in water treatment parameter control, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of difficult monitoring of separation efficiency, low separation energy utilization, etc. The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

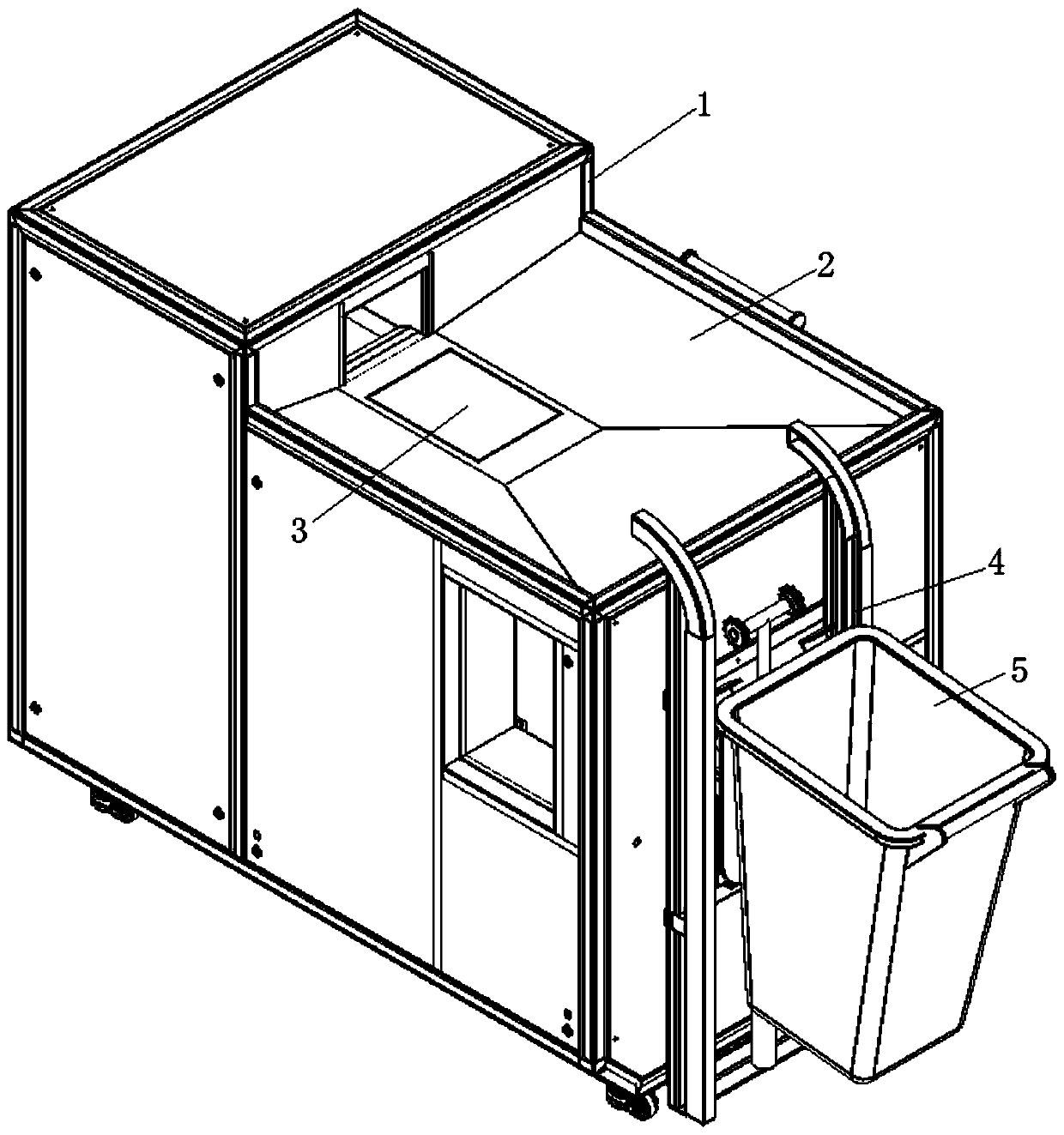

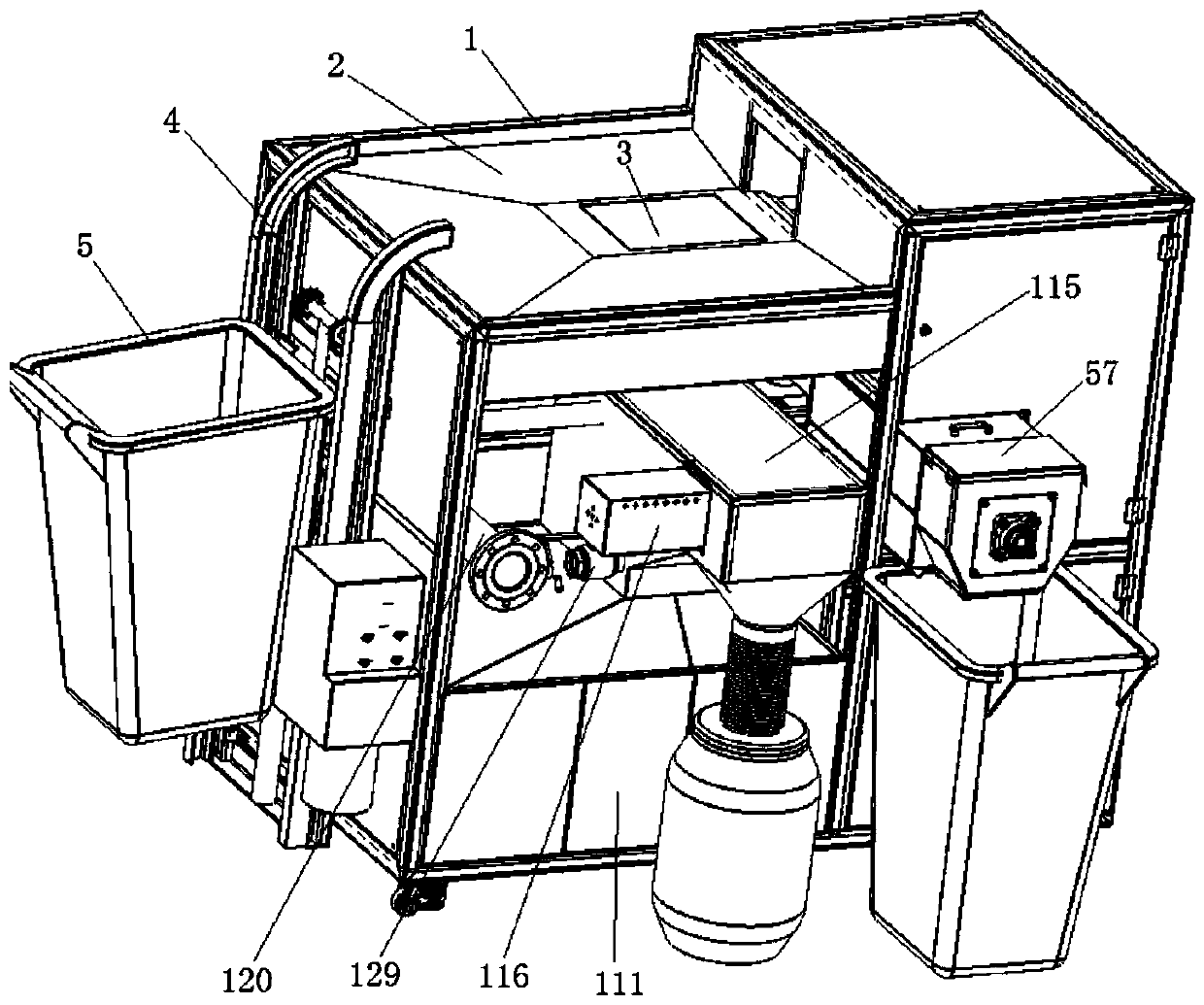

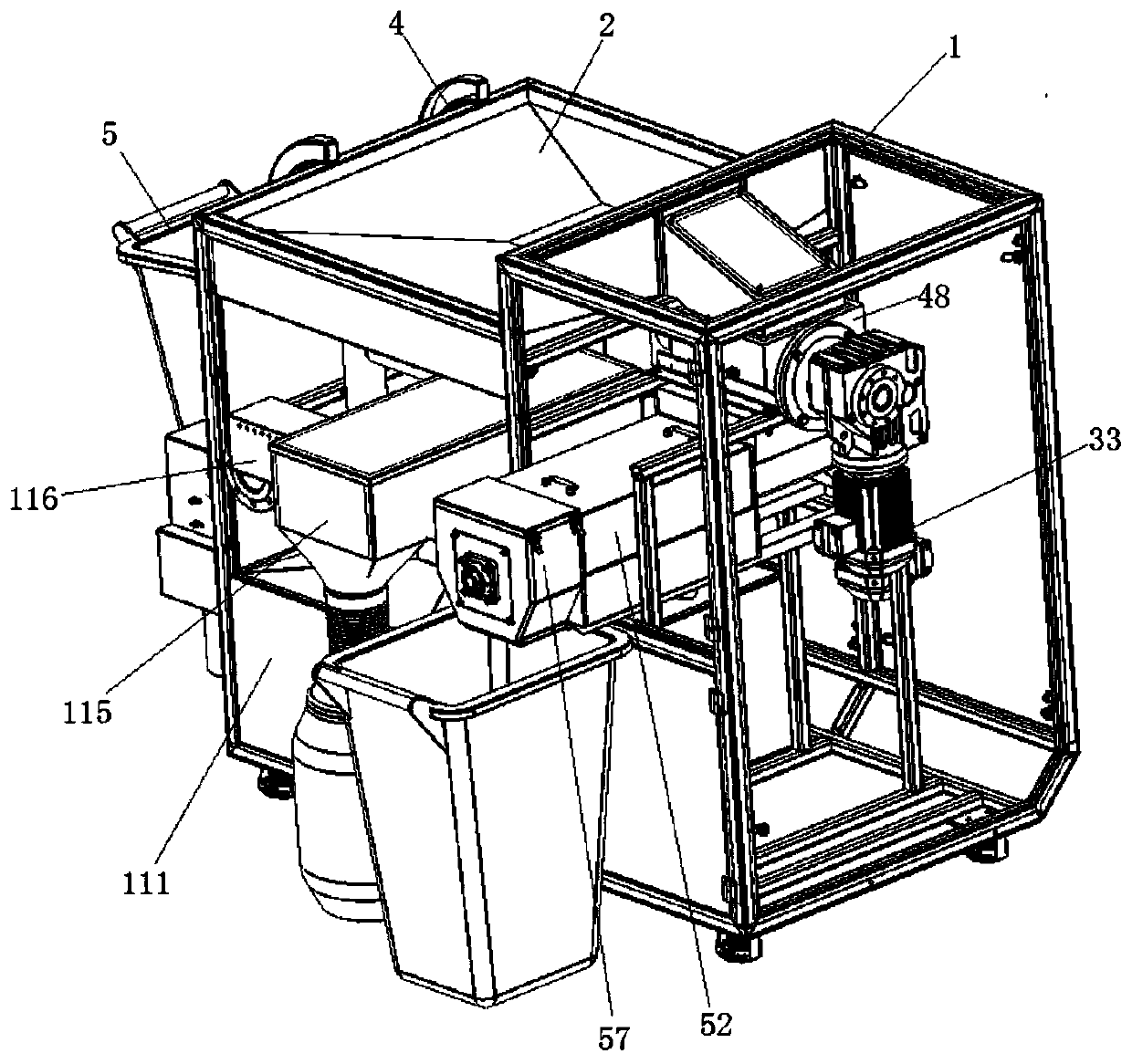

[0059] This embodiment provides a remote monitoring and control system for three-phase separation of swill, and the monitoring and control system is used to monitor and control a three-phase separation device for swill. Among them, the three-phase separation device for swill includes a feeding system, a sorting system, a crushing system, an extrusion system and an oil-water separation system. The feeding system is used to transport the food waste to be separated into three phases to the sorting system. The sorting system is used to sort and separate food waste to remove hard foreign matter, and obtain solid wet waste and liquid oil-water mixture. The crushing system is used to crush wet garbage to obtain crushed products whose particle size meets a preset particle size standard. The extrusion system is used to extrude and dehydrate the crushed product, and obtain the extruded water and the extruded material whose moisture content reaches a preset dry humidity. The oil-water ...

Embodiment 2

[0075] This embodiment provides a remote monitoring and control system for three-phase separation of swill, which adds multiple temperature detection modules on the basis of Embodiment 1. Multiple temperature detection modules are respectively used to detect temperature information of materials in the feeding system, sorting system, crushing system, extrusion system and oil-water separation system. The remote monitoring control platform is also used to display temperature information. The temperature detection module can detect the temperature of the materials in each system, so that the remote monitoring and control platform can display the temperature of each system, so that the monitoring personnel can grasp the real-time temperature of the materials in each system in time, so that the monitoring personnel can monitor the temperature of the materials in the system. If it is too low and condenses, it will be found and dealt with in time to improve the service life of the equ...

Embodiment 3

[0077]This embodiment provides a remote monitoring and control system for three-phase separation of swill, which adds multiple cameras and wireless transmission modules on the basis of Embodiment 1. Multiple cameras are used to take images of materials in the feeding system, sorting system, crushing system, extrusion system and oil-water separation system. The wireless transmission module is used to transmit the image information captured by multiple cameras to the remote monitoring and control platform, and is also used to transmit the data detected by the feeding monitoring module, sorting monitoring module, crushing monitoring module, extrusion monitoring module, and oil-water separation monitoring module And the efficiency information calculated by the data processing module is transmitted to the remote monitoring and control platform. The remote monitoring and control platform is also used to display the images captured by each camera in real time.

[0078] The remote mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com