Efficient garbage composting barrel

A waste composting and high-efficiency technology, applied in the direction of organic fertilizer, climate change adaptation, etc., can solve the problems affecting the activity level of microbial strains, the quality of fertilizer production cannot be guaranteed, and the water cannot be discharged in time, so as to achieve good drainage effect and good thermal insulation effect. , the effect of promoting circulation and heat and cold exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

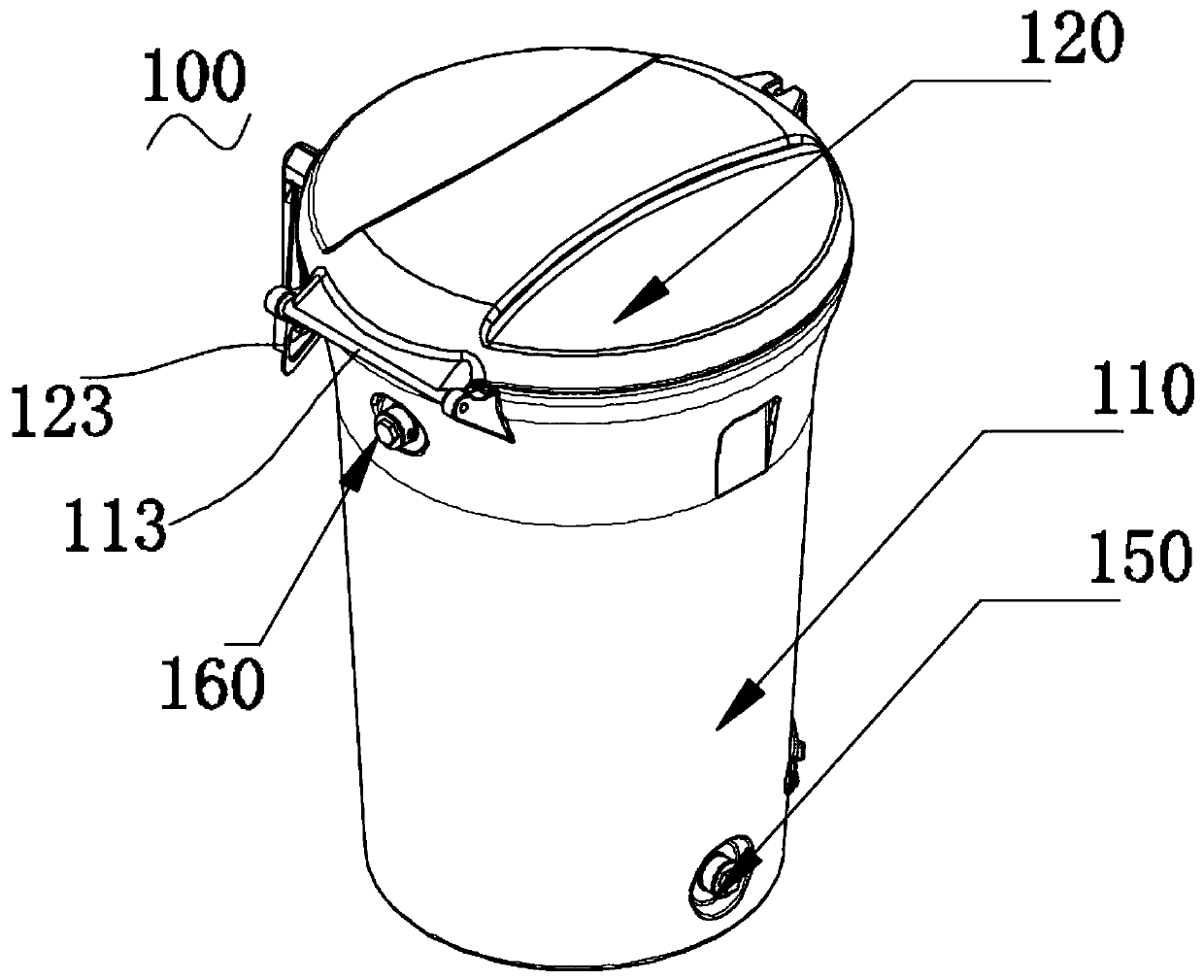

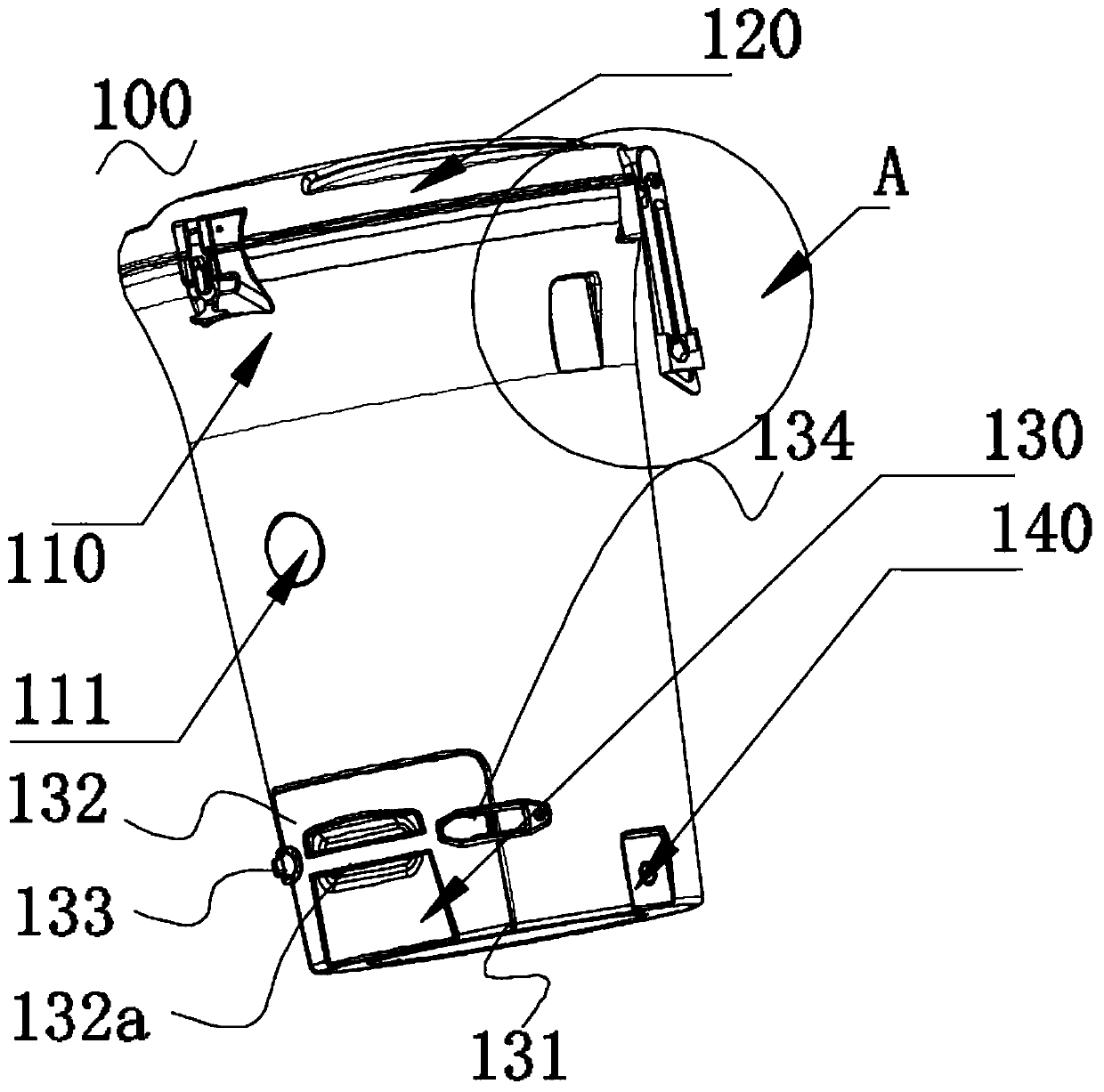

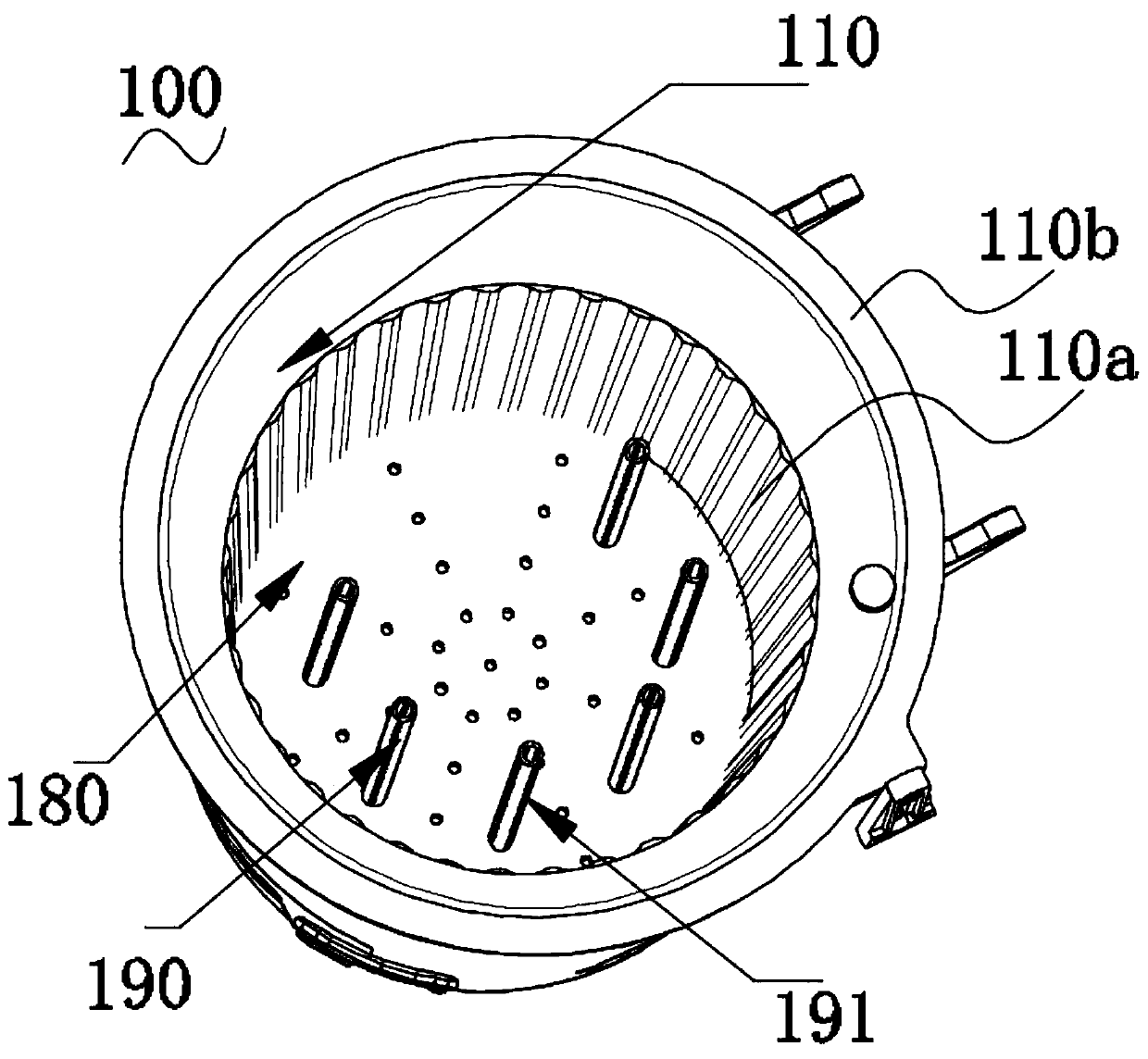

[0037] Such as Figure 1 ~ Figure 4 As shown, they are perspective views of different viewing angles, a schematic structural view after opening the barrel lid, and a partially enlarged view of the present invention.

[0038] The high-efficiency garbage compost bucket 100 includes a bucket body 110 for containing garbage, an openable lid 120 connected to the top of the bucket body 110 for feeding garbage and composting, and located at the bottom of the bucket body 110 for discharging compost. The silo 130 is set at the bottom of the barrel 110 near the liquid outlet 140 for leachate discharge, and the inlet valve 150 and the gas outlet valve 160 on the barrel 110 are set on the barrel 110 and extend into the barrel The temperature sensor 111 inside the body 110; it also includes a water filter plate 180 embedded in the inside of the barrel body 110, and several drain v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com