Boron-nitrogen co-doped carbon quantum dot as well as preparation and application thereof

A technology of carbon quantum dots and co-doping, which is applied in the direction of measuring devices, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of short emission wavelength and low fluorescence quantum yield, and achieve reaction Short time, excellent fluorescence characteristics, and good experimental repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

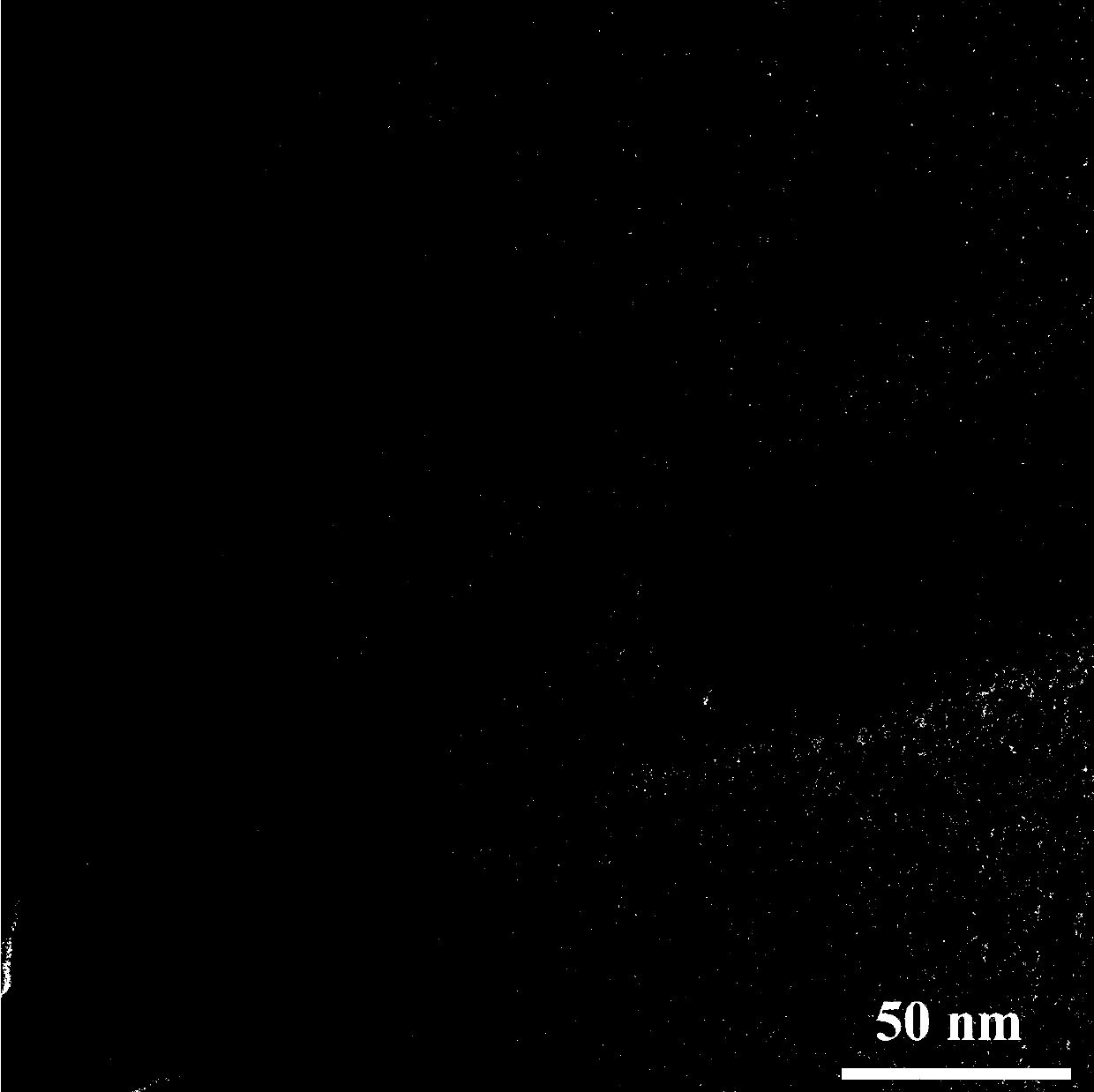

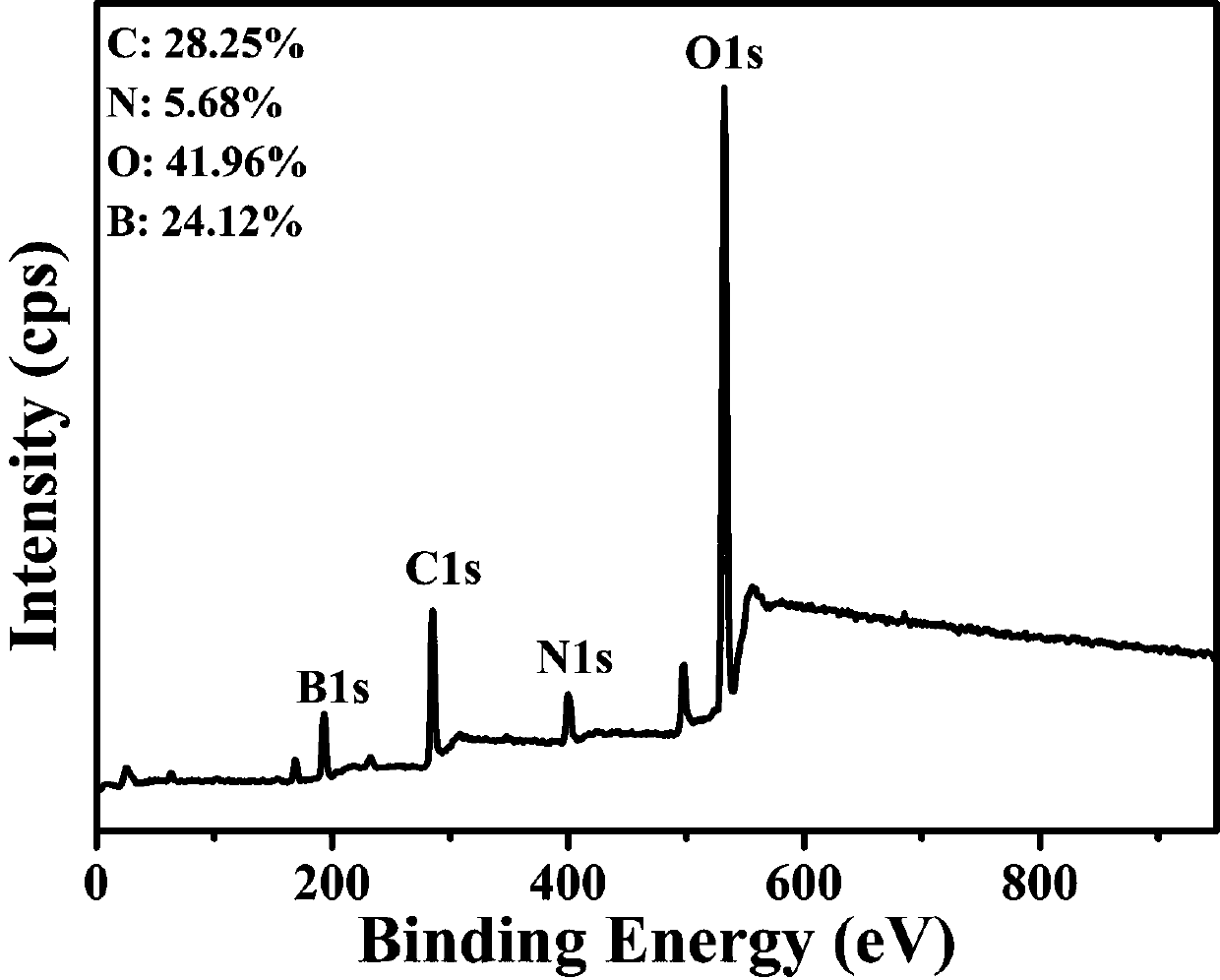

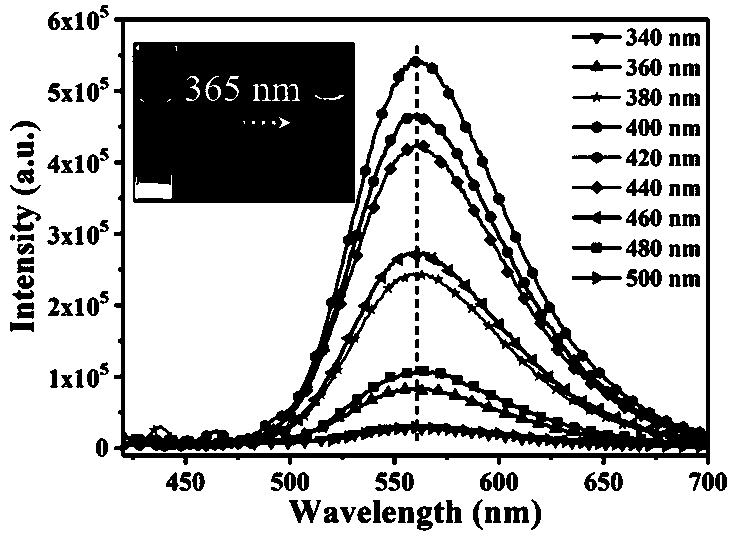

[0035] Weigh 0.27g (2.5mmol) of o-phenylenediamine and 0.15g (2.4mmol) of boric acid, add them into 10mL of ultrapure water, stir at room temperature until completely dissolved, and obtain a precursor solution.

[0036] The precursor solution was sealed in a glass tube for a microwave synthesizer, heated to 200° C. in a microwave with a working pressure of 30 bar, and cooled to room temperature after a hydrothermal reaction for 10 minutes to prepare a brown solution.

[0037] Filter the above brown solution with a 0.22 μm microporous membrane to remove large particles of impurities to obtain a light brown solution. Then put the solution in a dialysis bag with a molecular weight cut-off of 1000Da and dialyze for not less than 48 hours to remove unreacted or by-product small molecules to obtain a purified solution. During this period, the water was changed every 12 hours.

[0038] The purified solution in the dialysis bag is collected and dried to obtain a boron-nitrogen co-dop...

Embodiment 2

[0051] Weigh 0.27g (2.5mmol) of o-phenylenediamine and 0.15g (2.4mmol) of boric acid, add them into 10mL of ultrapure water, stir at room temperature until completely dissolved, and obtain a precursor solution.

[0052] The precursor solution was sealed in a glass tube for a microwave synthesizer, heated to 220° C. in a microwave with a working pressure of 30 bar, and cooled to room temperature after a hydrothermal reaction for 40 minutes to prepare a brown solution.

[0053] Filter the above brown solution with a 0.22 μm microporous membrane to remove large particles of impurities to obtain a light brown solution. Then put the solution in a dialysis bag with a molecular weight cut-off of 1000Da and dialyze for not less than 48 hours to remove unreacted or by-product small molecules to obtain a purified solution. During this period, the water was changed every 12 hours.

[0054] The purified solution in the dialysis bag is collected and dried to obtain a boron-nitrogen co-dop...

Embodiment 3

[0056] Weigh 0.27g (2.5mmol) of o-phenylenediamine and 0.23g (3.75mmol) of boric acid, add them into 10mL of ultrapure water, stir at room temperature until completely dissolved, and obtain a precursor solution.

[0057] The precursor solution was sealed in a glass tube for a microwave synthesizer, heated to 180° C. in a microwave with a working pressure of 30 bar, and cooled to room temperature after a hydrothermal reaction for 10 minutes to prepare a brown solution.

[0058] Filter the above brown solution with a 0.22 μm microporous membrane to remove large particles of impurities to obtain a light brown solution. Then put the solution in a dialysis bag with a molecular weight cut-off of 1000Da and dialyze for not less than 48 hours to remove unreacted or by-product small molecules to obtain a purified solution. During this period, the water was changed every 12 hours.

[0059] The purified solution in the dialysis bag is collected and dried to obtain a boron-nitrogen co-do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com