Dust-free type textile equipment

A technology for textile equipment and piston blocks, which is applied in textiles and papermaking, etc., can solve the problems of lack of kinetic energy, poor dust removal effect, and lack of guide components, so as to ensure efficiency and increase practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

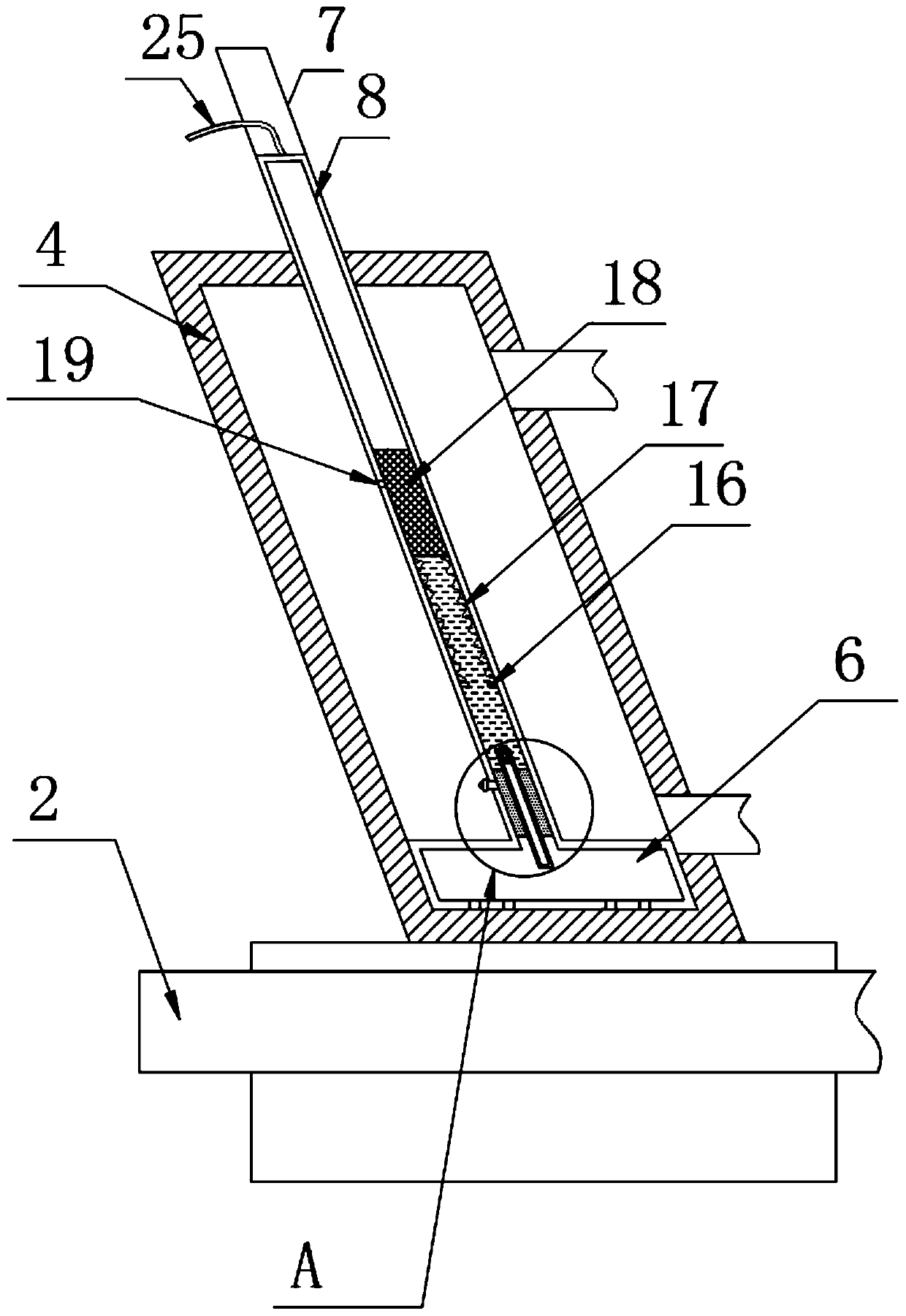

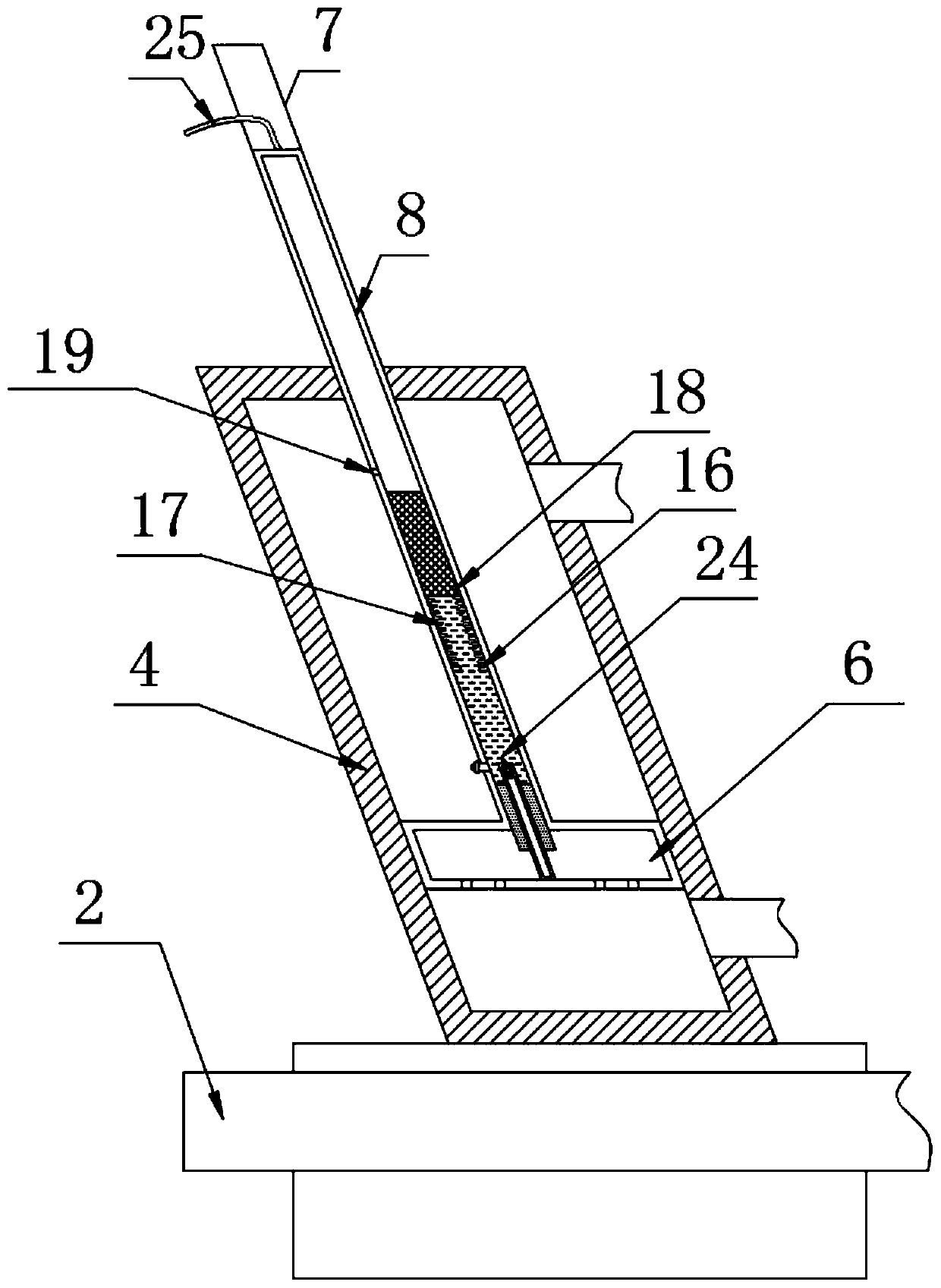

[0037] Embodiment 2 specifically refers to the specification attached Figure 6-7

[0038] Embodiment 2 is specifically different from Embodiment 1 in that a first magnetic block 21 is fixedly installed on the bottom surface of the bar-shaped piston block 18, a second magnetic block 22 is fixedly installed on the inner wall of the water storage tank 8, and the first magnetic block 21 and the second magnetic block 22 are annular, and the top magnetic pole of the second magnetic block 22 is the same as the bottom magnetic pole of the first magnetic block 21 .

[0039] Using the above-mentioned technical means: utilizing the principle that the first magnetic block 21 and the second magnetic block 22 repel each other with the same pole, so that when the top of the bar-shaped piston block 18 loses the air pressure, the bar-shaped piston block 18 can be quickly moved upwards to recover, , so that the strip-shaped piston block 18 moves up and down in a reciprocating line, that is, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com