Motor-undermounted window lifter system used for automobile windows

A technology of window shaker and car window, which is applied to the control mechanism of wing leaf, door/window accessories, power control mechanism, etc. Stable structural performance, smooth lifting movement, smooth lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

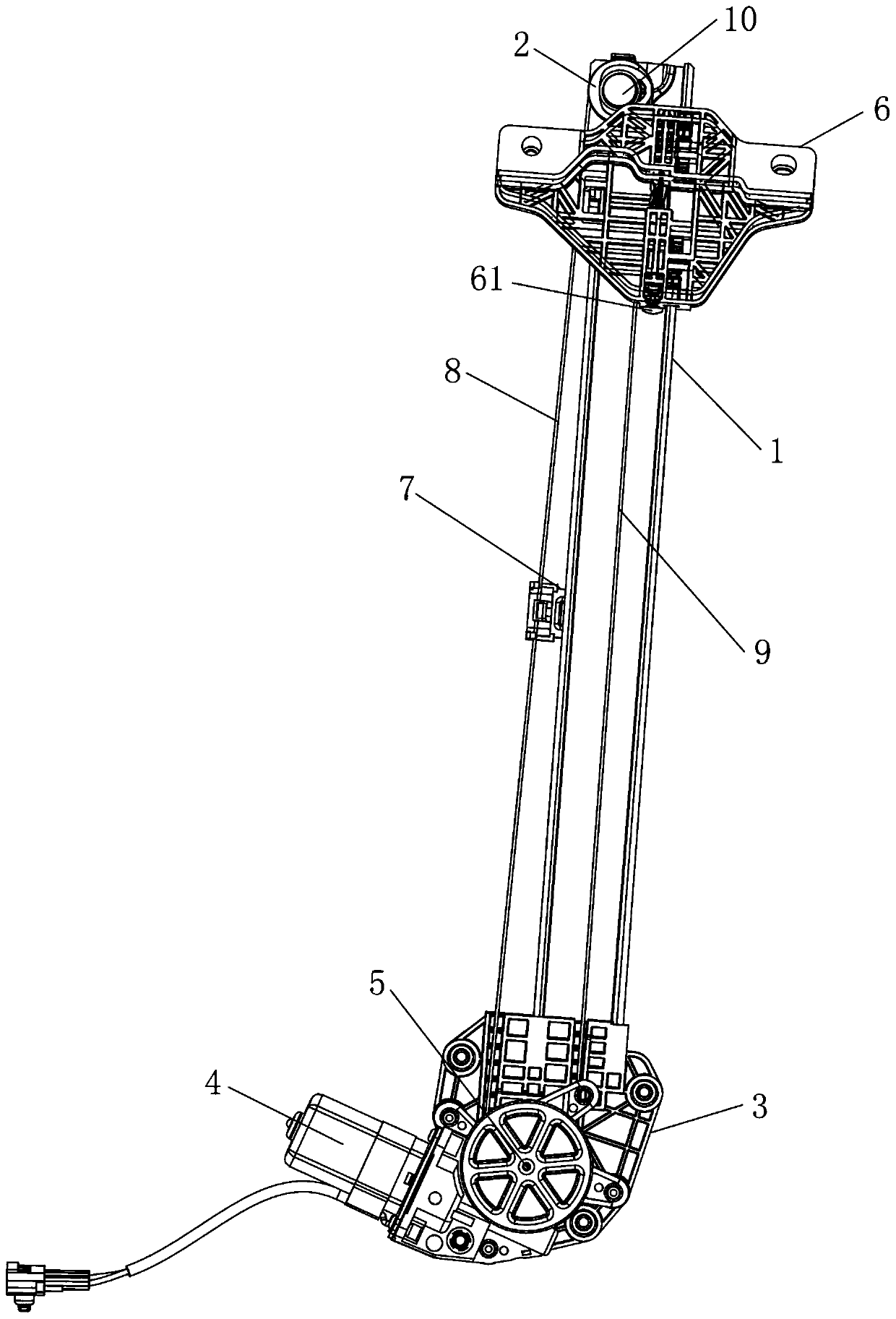

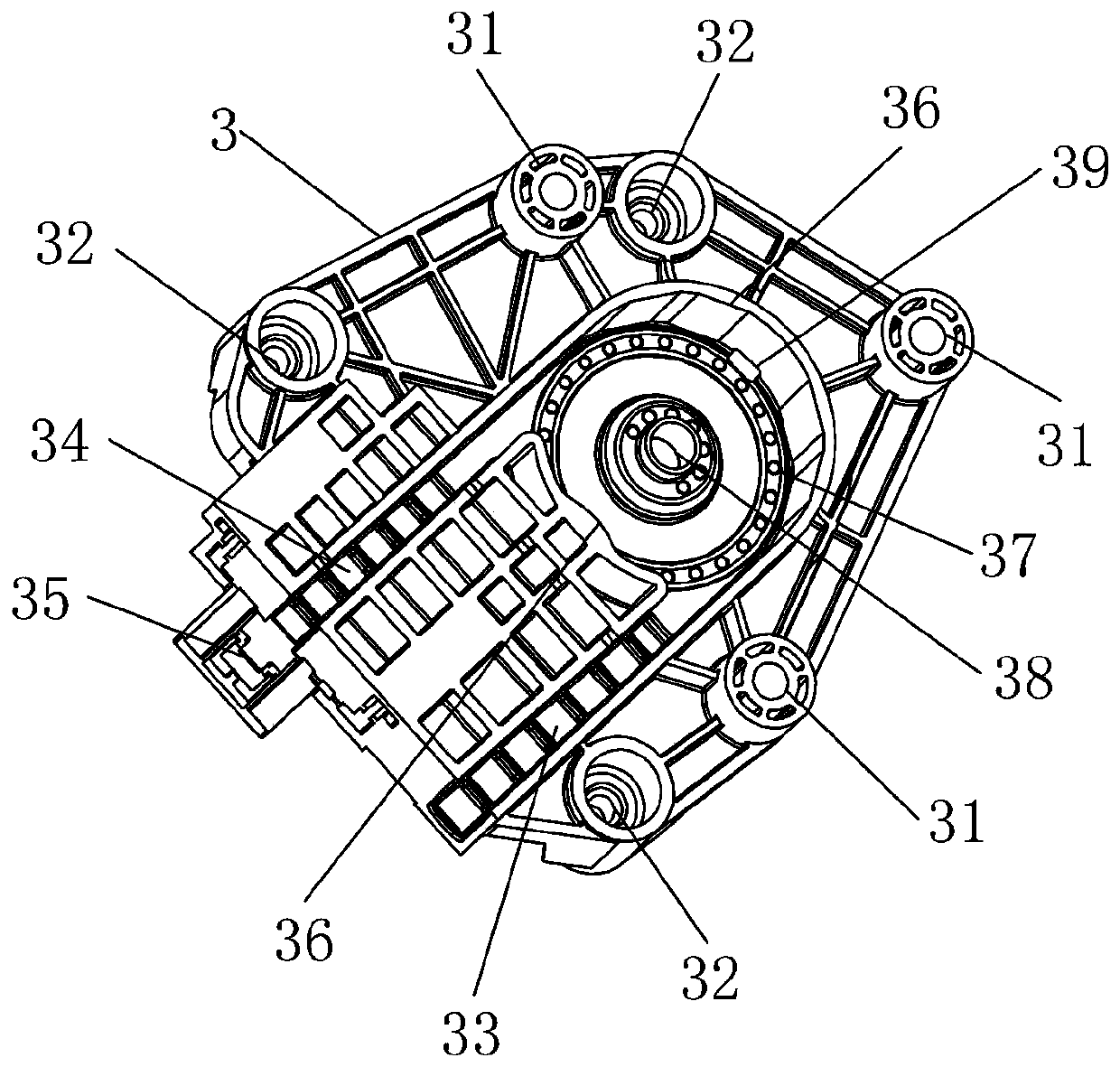

[0036] like Figure 1 to Figure 11As shown, a motor-mounted window shaker system for automobile windows includes a guide rail 1, a guide wheel 2 and a motor 4, the guide wheel 2 is installed on the top of the guide rail 1, and the guide wheel 2 of this embodiment is riveted by a hollow rivet At the upper end of the guide rail, the upper buffer block 10 is an umbrella-shaped Y-direction rubber buffer block. The upper buffer block 10 is assembled on the hollow rivet through the center hole of the hollow rivet. The rod part of the upper buffer block 10 is an interference fit with the center hole. The effect of buffer block (being upper buffer block 10) is to prevent glass from shaking and colliding with guide rail 1 in the glass normal direction. The bottom of the guide rail 1 is plugged and fixedly installed with a cover plate 3, a motor 4 is fixed on the cover plate 3, a winding wheel 5 is installed on the motor shaft of the motor 4, the winding wheel 5 is designed with inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com