Hydraulic-mechanical combined rock-breaking tbm device and rock-breaking method

A mechanical and hydraulic technology, applied in the field of tunnels and underground engineering, can solve the problems of large changes, large rock force, waste of water resources, etc., and achieve the effect of reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0183]A subway tunnel is mainly composed of multiple rock mass composite strata.

[0184] The hydraulic-mechanical combined rock-breaking TBM device 25 of the present invention is used to excavate tunnels; when the hydraulic-mechanical combined rock-breaking TBM device 25 is working, the worker will combine the mechanical hob structure 9 with the hydraulic power of the combined rock-breaking The cutting tool module 7 is installed on the TBM cutter head structure 23, and the knives equipped on the TBM cutter head structure 23 have sufficient strength and rigidity, and can withstand the huge reaction force generated by the cutter head rotating and propelling when the main engine is driving. and shear stress; the rotary drive 12 on the TBM cutter head structure 23 controls the rotation of the TBM cutter head structure 23, and the propulsion cylinder 13 pushes the TBM cutter head structure 23 to advance forward.

[0185] The hydraulic cutting tool module 7 combined with rock break...

Embodiment 2

[0199] A subway tunnel is mainly composed of multiple rock mass composite strata.

[0200] Embodiment 2 carries out hydraulic-mechanical TBM joint rock breaking to a certain subway tunnel, and its method is the same as embodiment 1; the difference is: the hydraulic cutting tool module 7 of the combined rock breaking adopted in this embodiment is set to: TBM of the present invention The cutter head structure is a combined cutter head structure based on the combined rock-breaking hydraulic cutting tool module. Three adjacent hydraulic cutting tool modules on the same circular track form a whole. Knife and widening water jet, the cracking water jet is used to complete the preliminary grooving and cracking of rocks, the depth of cut water jet and the widening water jet are consistent with the groove cutting path of the cracking water jet; the three Two hydraulic cutting tool modules constitute a combined whole, located in the center between two adjacent mechanical hob structures 9...

Embodiment 3

[0204] A subway tunnel is mainly composed of multiple rock mass composite strata.

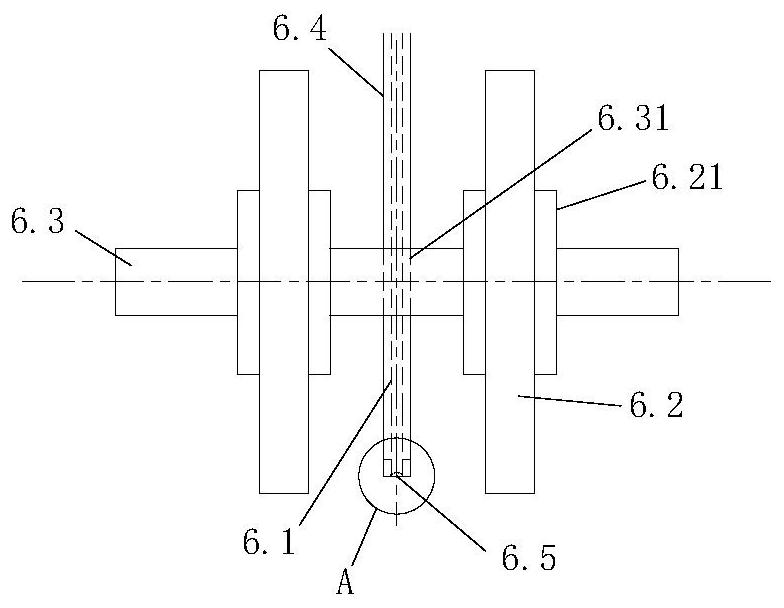

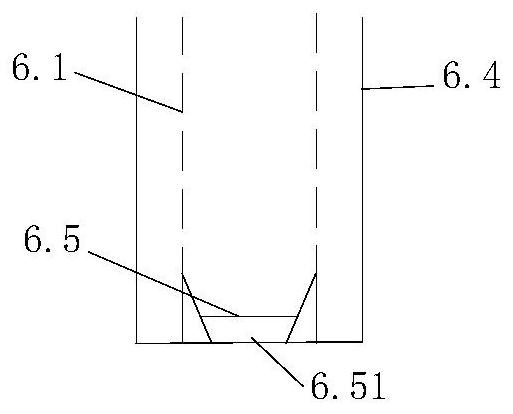

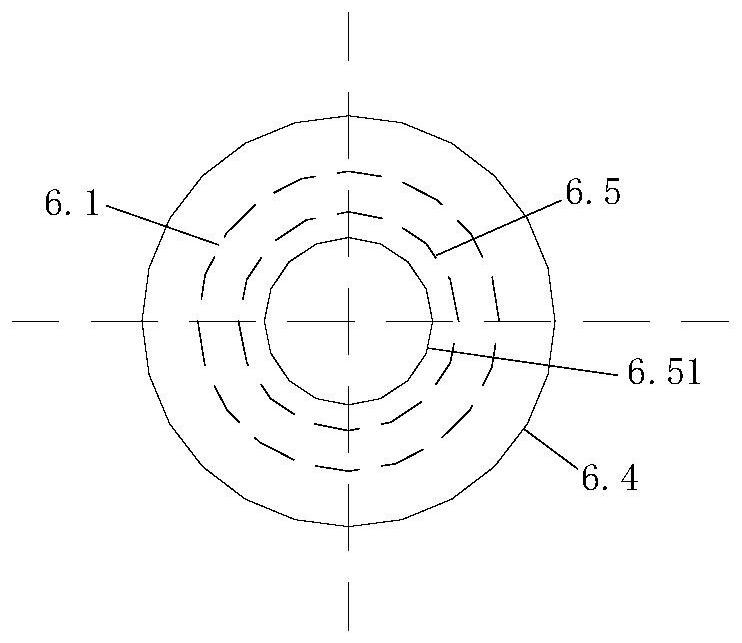

[0205] Embodiment 3 carries out hydraulic-mechanical TBM joint rock breaking to a certain subway tunnel, and its method is the same as embodiment 1; There are three pipelines 6.1; there are three high-pressure water pipeline protection sleeves 6.4; Be provided with a described high-pressure water pipeline 6.1) (such as Figure 8 , Figure 9 , Figure 10 , Figure 11 shown); the TBM cutter head structure 23 of the hydraulic-mechanical combined rock-breaking TBM device 25 used in this embodiment (such as Figure 17 Shown); The rock-breaking operation of the present embodiment is as Figure 18 , Figure 19 , Figure 24 shown.

[0206] It should be noted that the number of water jet pipes and nozzles of the water cutting tool module shown in this embodiment is only used as a schematic illustration of the working principle of water cutting and rolling, and the number of water flow channels i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com