Wind turbine blade fault monitoring method and equipment based on acoustic sensor array

A technology of wind turbines and wind blades, applied in the monitoring of wind turbines, wind turbines, mechanical equipment, etc., can solve the problems of low management efficiency and high operation and maintenance costs, reduce maintenance time, improve operation and maintenance efficiency, increase The effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

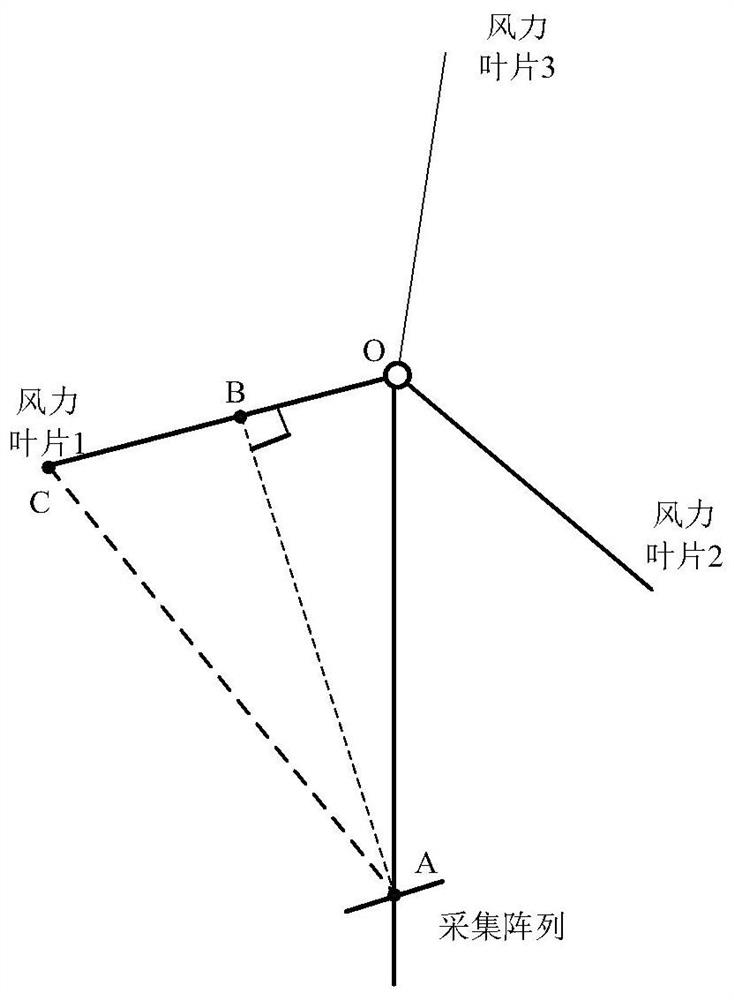

[0058] Such as figure 1 , Figure 5 , figure 1 A schematic diagram of the location of the acquisition array and the wind generator provided by the embodiment of the present invention; Figure 5 The flow block diagram provided for the embodiment of the present invention; the wind turbine blade fault monitoring method based on the acoustic sensor array, including a wind generator, the wind generator includes several wind blades, and the wind blades rotate around the tower, this embodiment In the middle are three wind blades, such as figure 1 The wind blade 1, the wind blade 2, and the wind blade 3, wherein the wind blade 1, the wind blade 2, and the wind blade 3 rotate around the tower, also include the following steps:

[0059] S1. Deploy the acquisition array, and pick up the sound signal of the blade through the acquisition array;

[0060] Such as figure 1 , the acquisition array is fixed on the bottom of the support rod of the wind turbine through bolts, and is in the s...

Embodiment 2

[0105] The monitoring equipment based on the acoustic sensor array-based wind turbine blade failure monitoring method includes a wind generator, the wind generator includes several wind blades, and the wind blades rotate around the tower, and also includes;

[0106] Deployment module, for deploying acquisition array;

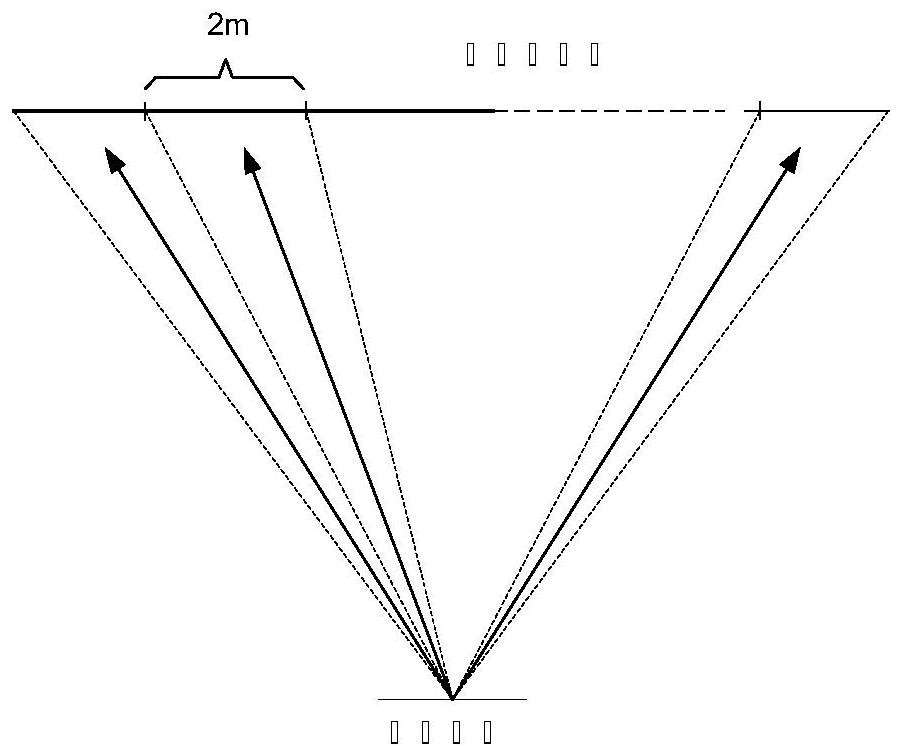

[0107] It also includes: the collection array is in the same plane as the rotating surface of the wind blade; at the same time, when the perpendicular line of the line segment of the wind blade passes through the midpoint of the collection array, the collection array is parallel to the wind blade;

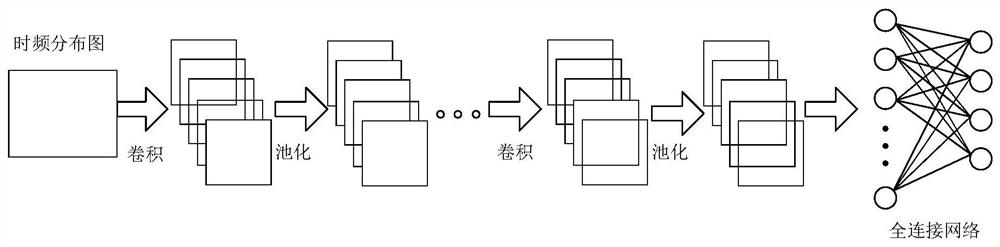

[0108] The enhancement module is used to enhance the blade sound signal picked up by the acquisition array, and construct a CNN fault judgment model;

[0109] It also includes: dividing the wind blades into m areas in units of n meters, the acquisition array determines a direction for each area, obtains m directions, and performs signal enhancement on the m direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com