Compressor, control method and air conditioner

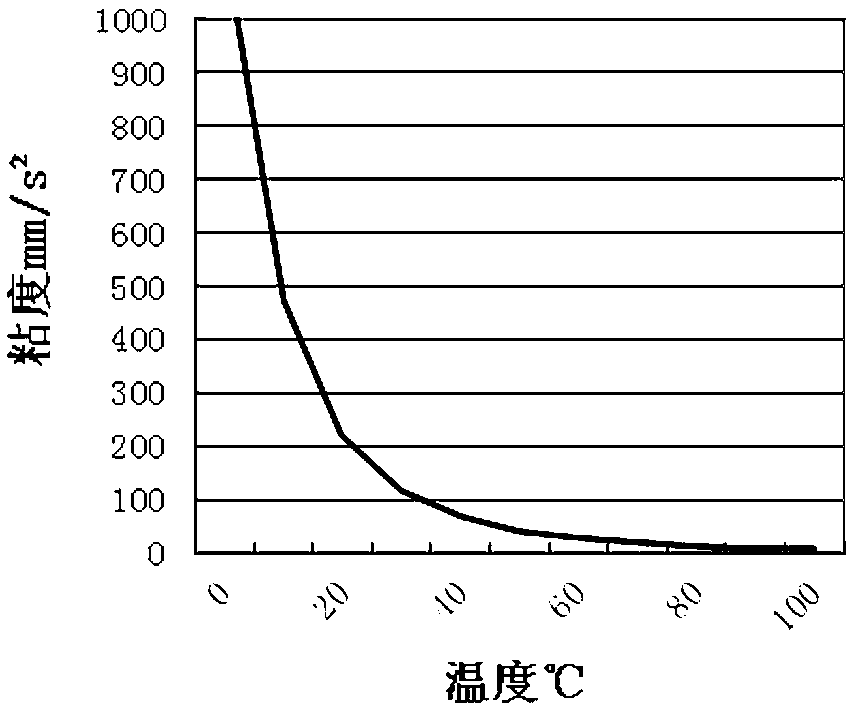

A control method and compressor technology, applied in the field of compressors, can solve problems such as high viscosity of internal lubricating oil, high power consumption of compressors, difficulty in starting, etc., and achieve the effects of reduced power consumption, increased energy efficiency, and increased temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a method for controlling a compressor.

[0030] This embodiment provides a compressor control method, including the following steps:

[0031] S1: Set the current of the motor 7 of the compressor 1 to X times the initial current;

[0032] The adjustment of the current magnitude when the motor 7 is in normal operation varies according to the load condition of the system. When the load of the compressor 1 is heavy and the torque requirement is large, the current passing through the motor 7 of the compressor 1 increases accordingly. Conversely, when the load of the compressor 1 is small and the torque requirement is small, the current passing through the motor 7 of the compressor 1 also decreases accordingly. After the compressor 1 is energized, the control module sets the current of the motor 7 of the compressor 1 to 1.4 times of the initial current, and realizes internal heating of the compressor 1 through the coil of the motor 7 of the compressor 1 and th...

Embodiment 2

[0039] Embodiment 2, a compressor.

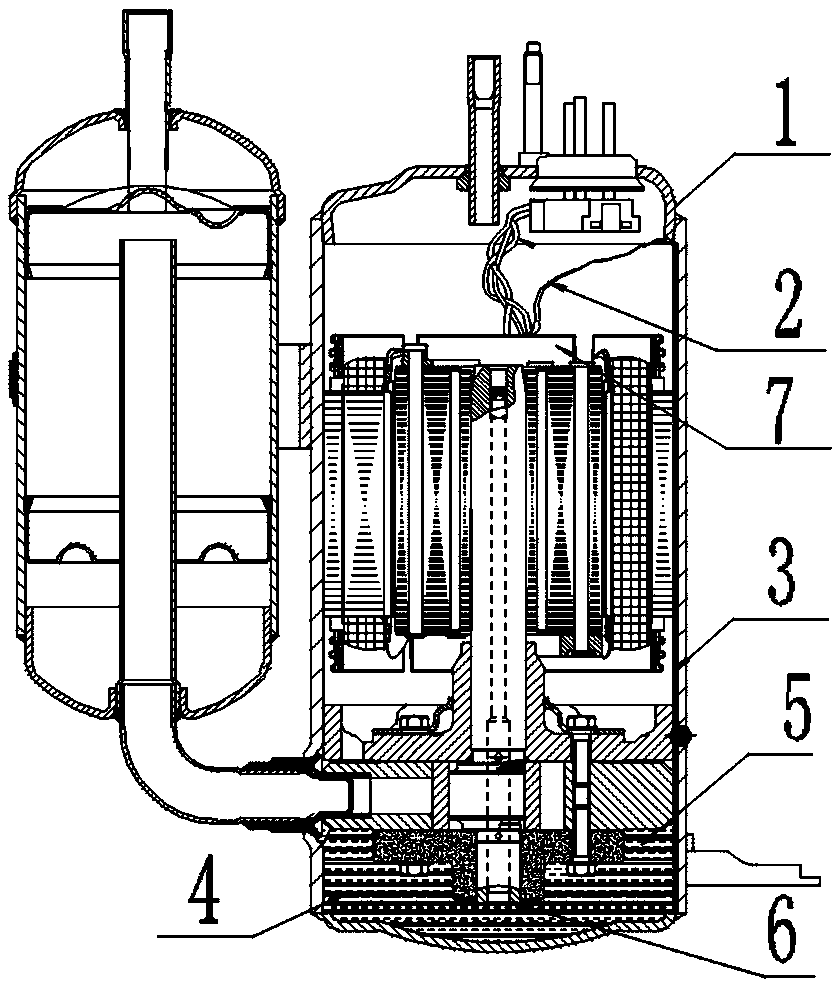

[0040] This embodiment provides a compressor such as figure 1 As shown, the compressor 1 of this embodiment is used to realize the control method of the compressor 1 described in the first embodiment.

[0041] Compressor 1 includes current transmission line 2, heating resistance wire, lubricating oil 5, motor 7, lubricating oil 5 temperature detection device, exhaust temperature detection device and control module, one end of current transmission line 2 is connected to the coil of motor 7, the other end of current transmission line 2 One end is connected to one end of the heating resistance wire, the other end of the heating resistance wire is immersed in lubricating oil 5, the lubricating oil 5 temperature detection device is set in the lubricating oil 5, the lubricating oil 5 temperature detection device is connected to the first port of the control module, and the exhaust The temperature detecting device is arranged at the exhaust port...

Embodiment 3

[0046] Embodiment 3, an air conditioner.

[0047] This embodiment provides an air conditioner, which includes the compressor 1 described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com