Hydraulic control system and its control method based on labview

A technology of hydraulic control system and control method, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problems that it is difficult to make breakthroughs, and achieve convenient data recording and comparison Experimental results, the effect of improving programming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

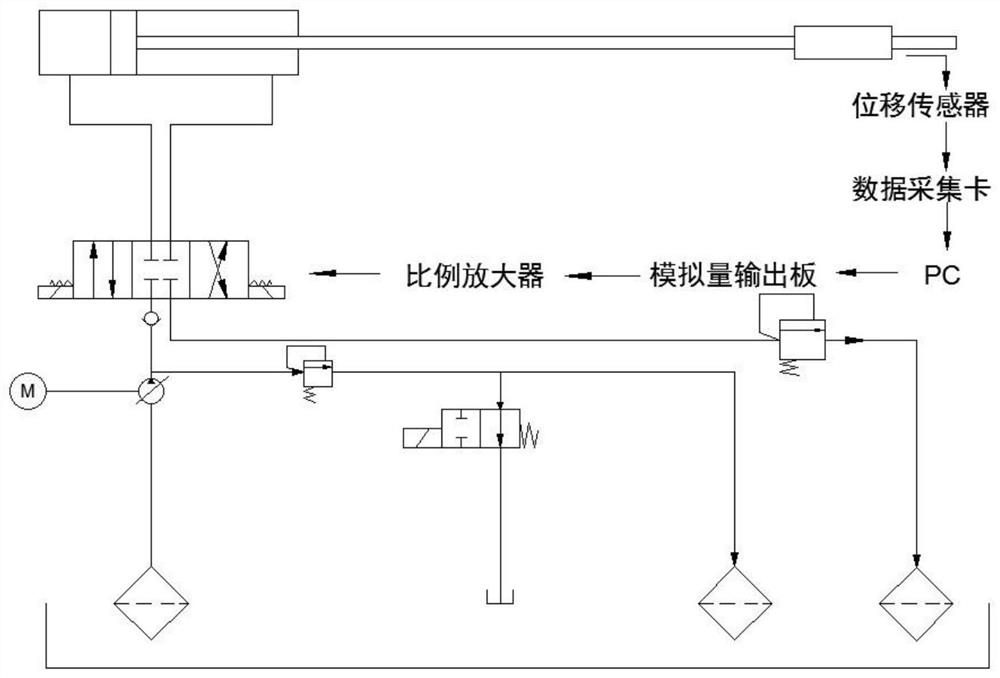

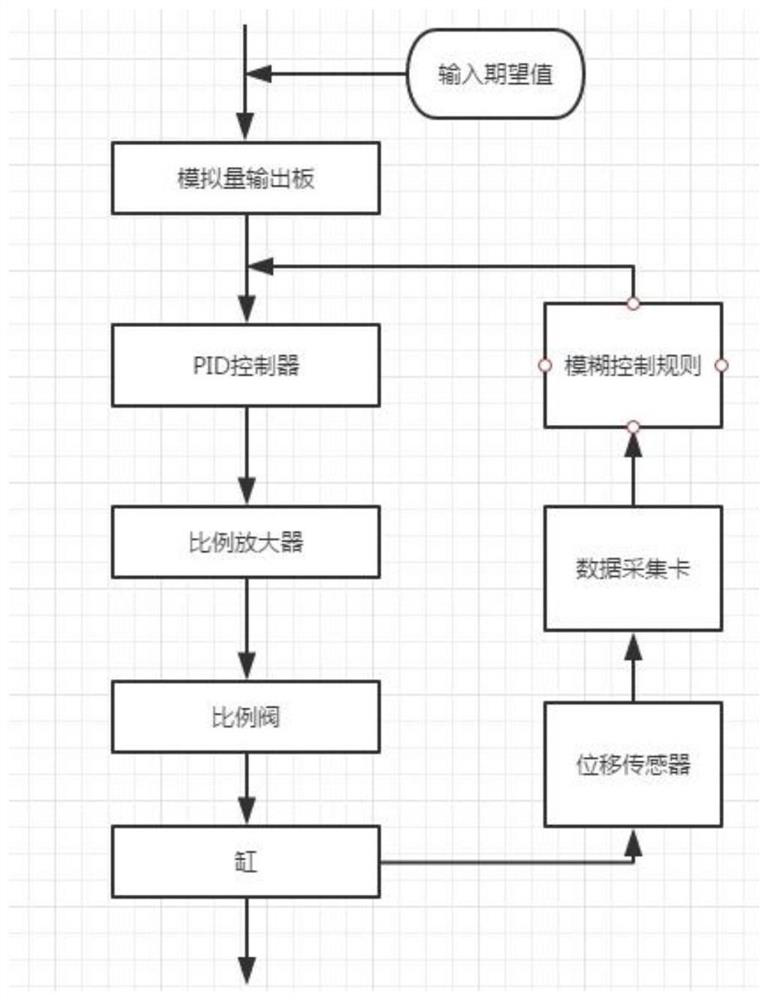

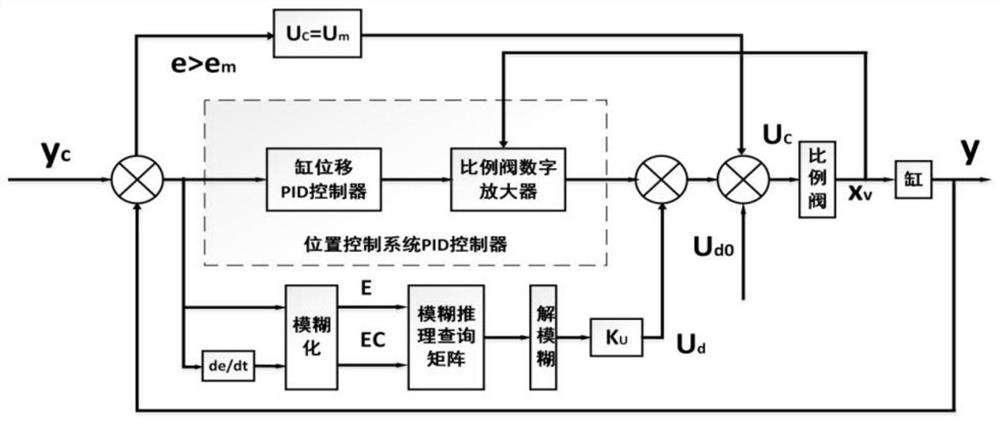

[0068] Embodiment: a kind of hydraulic control system based on LabVIEW, comprising: hydraulic cylinder, computer that LabVIEW is equipped with, proportional amplifier, directional valve, displacement sensor, and the serial port communication device that establishes communication interface layer for LabVIEW; Serial port communication device includes data acquisition card and analog output board.

[0069] The computer sends a control current signal to the proportional amplifier through the analog output board. The proportional amplifier amplifies the current signal and outputs it to the directional valve. The directional valve receives the current signal output by the proportional amplifier to control the flow direction and pressure of the oil in the hydraulic cylinder. The displacement of the hydraulic rod occurs, and the displacement sensor detects the displacement of the hydraulic rod, and sends the voltage signal generated by the displacement change of the hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com