Internal and external double-pneumatic-tube clutch

A clutch and dual-pneumatic tire technology, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of equipment size and weight restrictions, limited space in ship cabins, and heavy weight, etc., to achieve the goal of reducing equipment weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

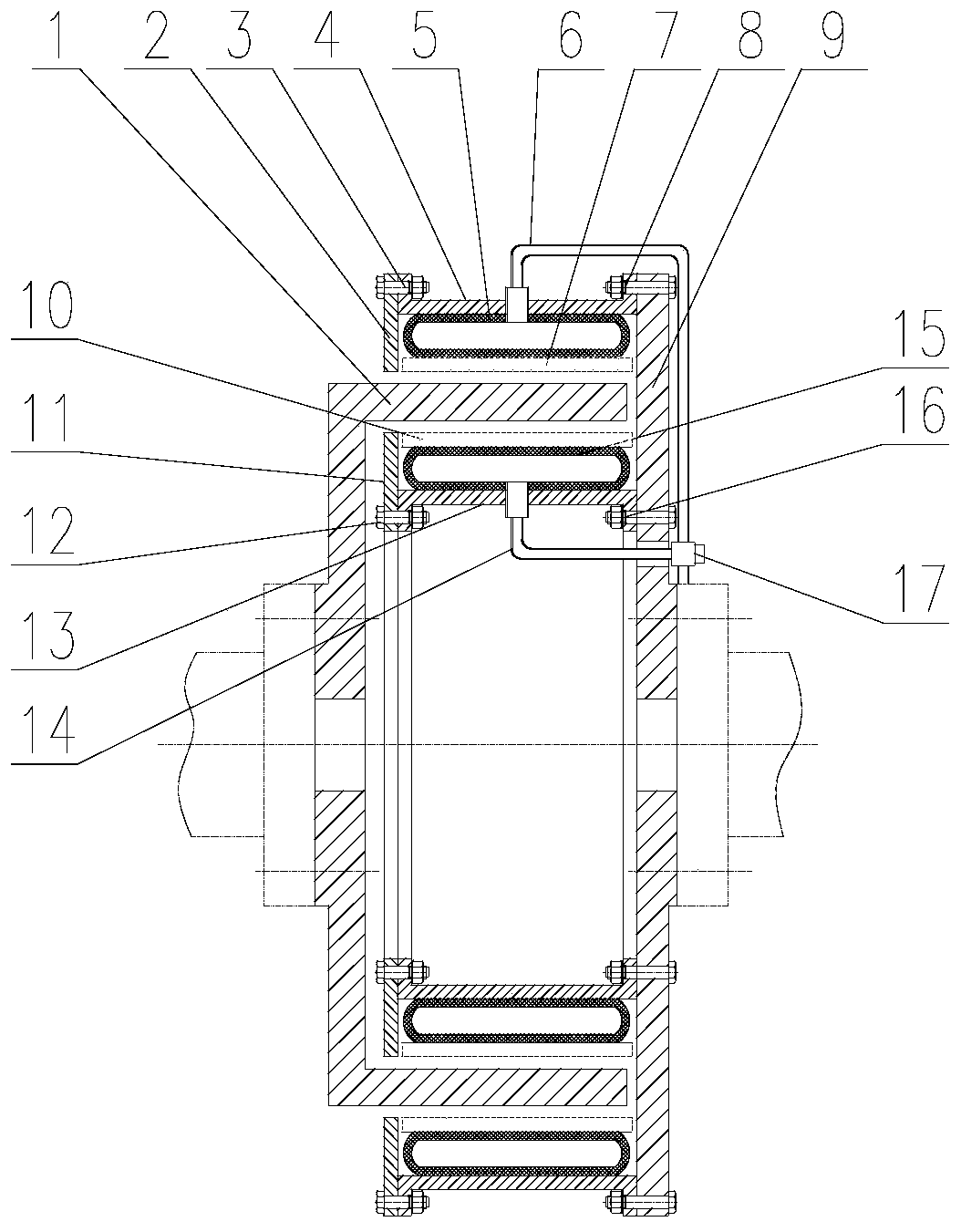

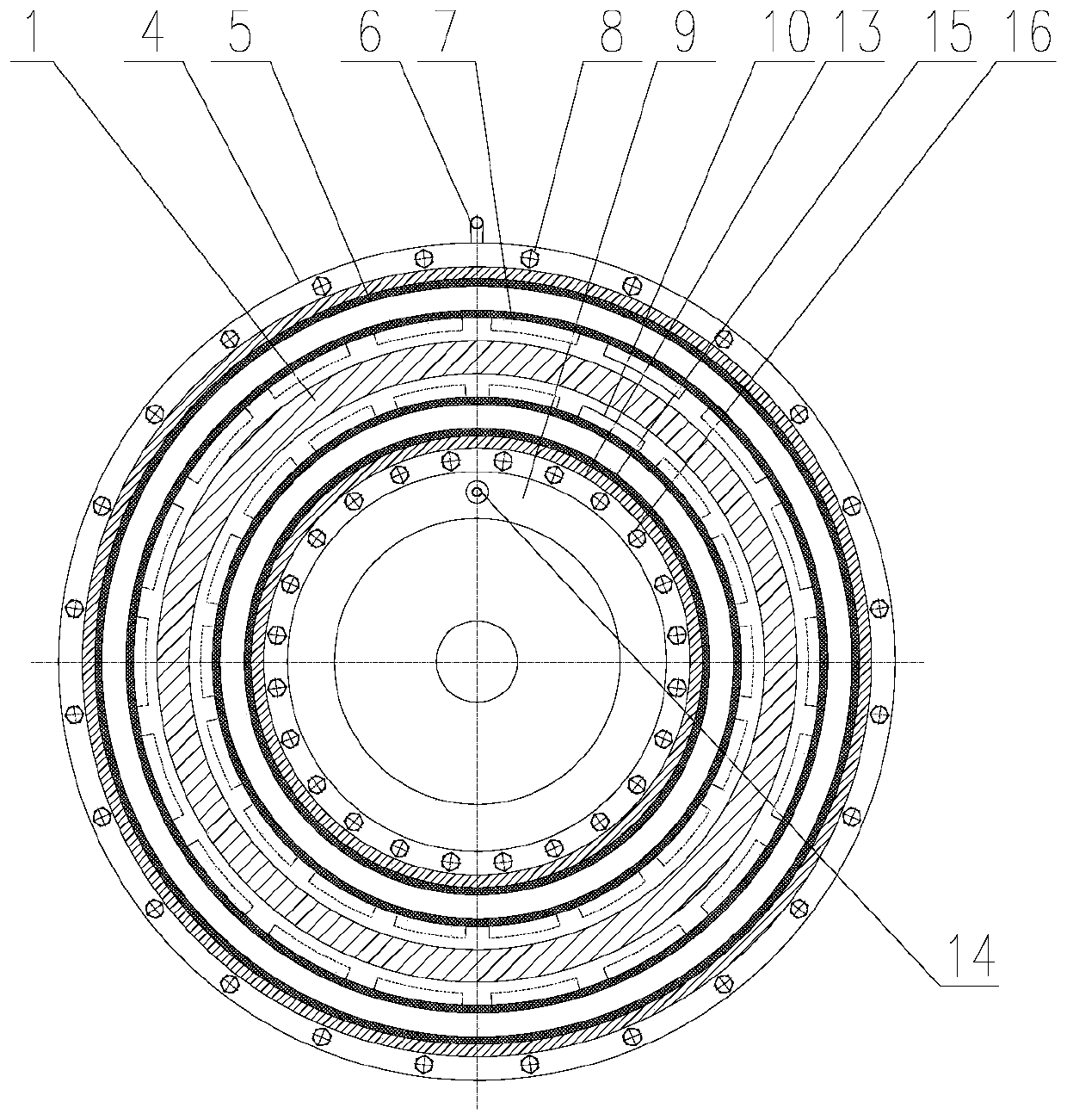

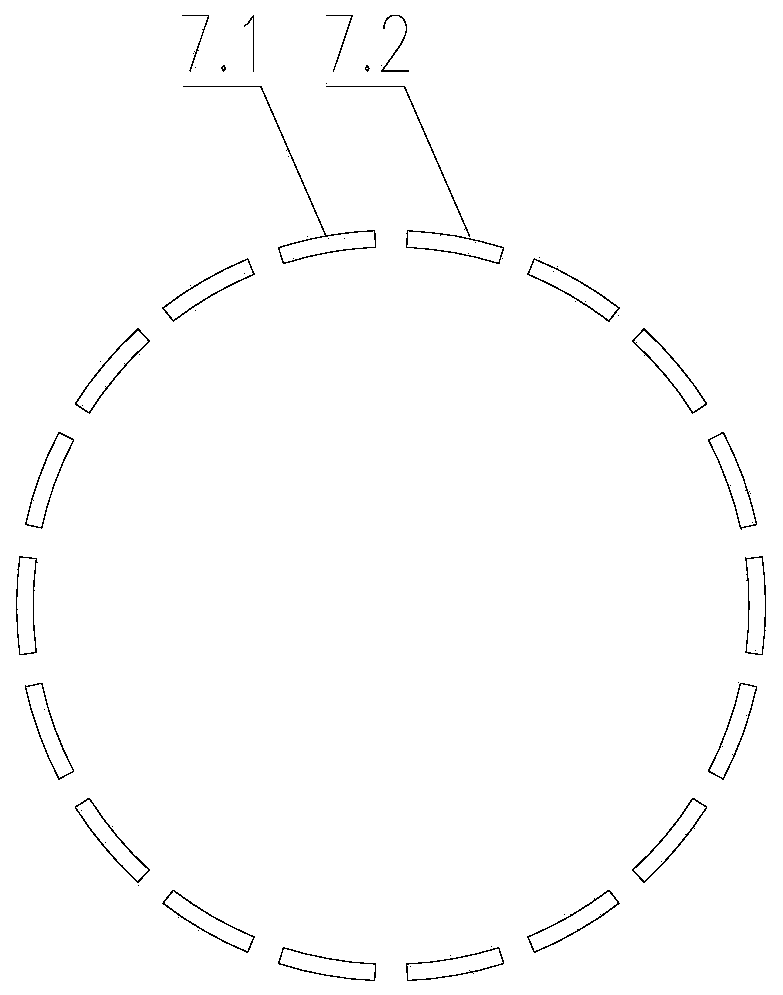

[0029] Such as figure 1 , shown in 2, a kind of internal and external dual-pneumatic tire clutch, consists of driving drum 1, external side plate 2, connecting bolt group 1 3, external external drum wheel 4, external pneumatic tire 5, external pneumatic tire tube Road 6, external friction plate group 7, connecting bolt group 2 8, driven disc 9, built-in friction plate group 10, built-in side plate 11, connecting bolt group 3 12, built-in outer drum wheel 13, built-in pneumatic tire pipeline 14 , Built-in pneumatic tire 15, connecting bolt group four 16, gas path summary joint 17 etc. are formed. Among them, the driving drum 1, the external side plate 2, the external external drum 4, the external pneumatic tire 5, the driven disc 9, the built-in side plate 11, the built-in external drum 13, and the built-in pneumatic tire 15 are all rotary parts.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com