Steel-lined poly tetra fluoroethylene (PTFE) pipe

A technology for lining PTFE pipes and steel pipes, applied in the field of steel lining PTFE pipes, can solve the problems of expansion deformation, bulging and deflation, insufficient pressure resistance, etc., to increase axial support force, improve negative pressure resistance, avoid shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

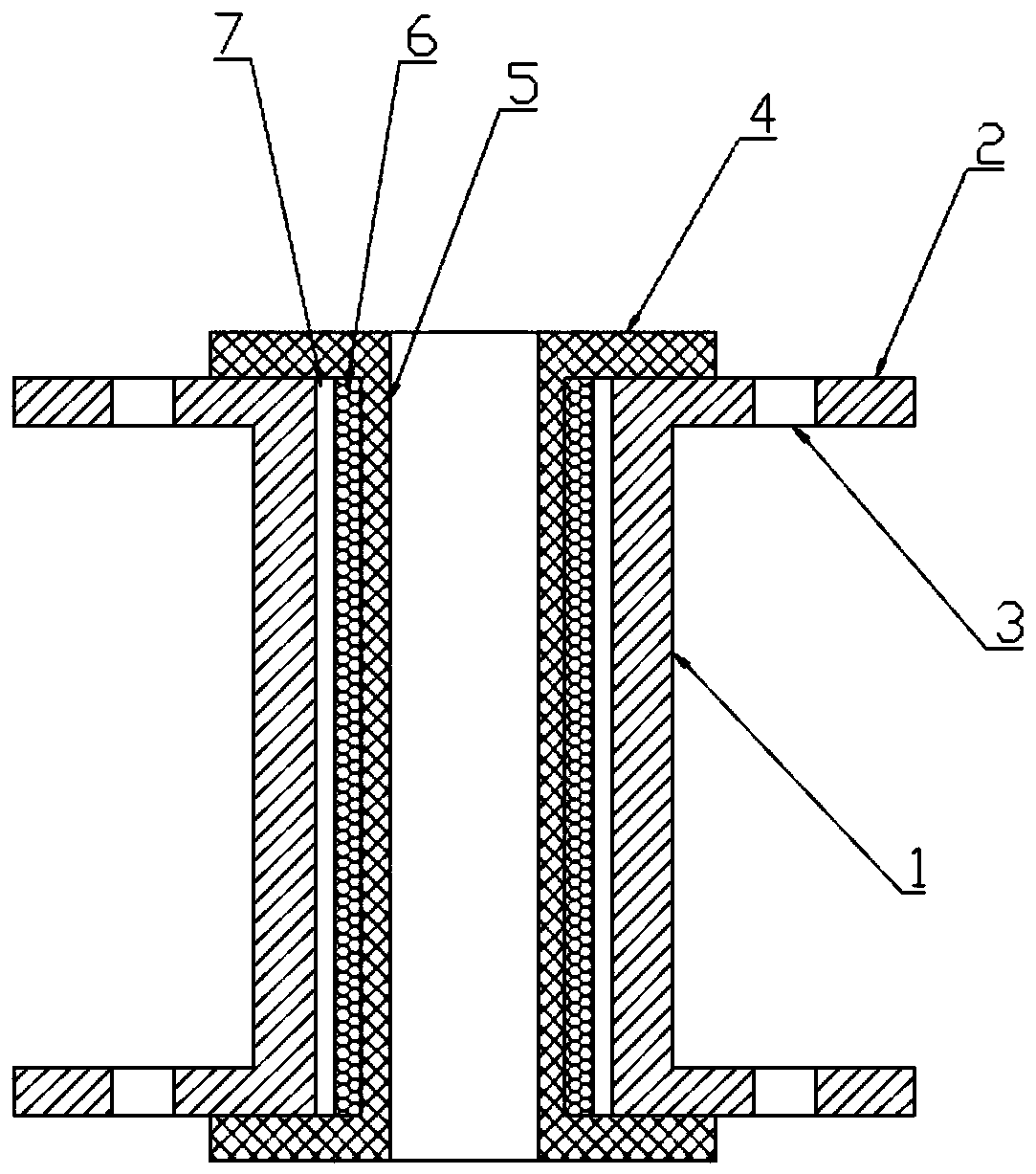

[0019] like figure 1 As shown, a steel-lined tetrafluoro pipe includes a steel pipe body 1, a polytetrafluoroethylene lining 5, and a steel wire turn 6,

[0020] The two ends of the steel pipe body 1 are respectively provided with flanges 2, and a plurality of installation holes 3 are evenly arranged on the flange 2 in a circumferential direction, and the polytetrafluoroethylene lining 5 is arranged in the hollow channel of the steel pipe body 1, so that The polytetrafluoroethylene lining 5 is cylindrical, and T-shaped protrusions 4 are respectively arranged at both ends, and the T-shaped protrusions 4 are closely attached to the flange 2,

[0021] The steel wire turn 6 is closely attached to the outer wall of the straight pipe of the polytetrafluoroethylene lining 5, the steel wire is wound on the polytetrafluoroethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com