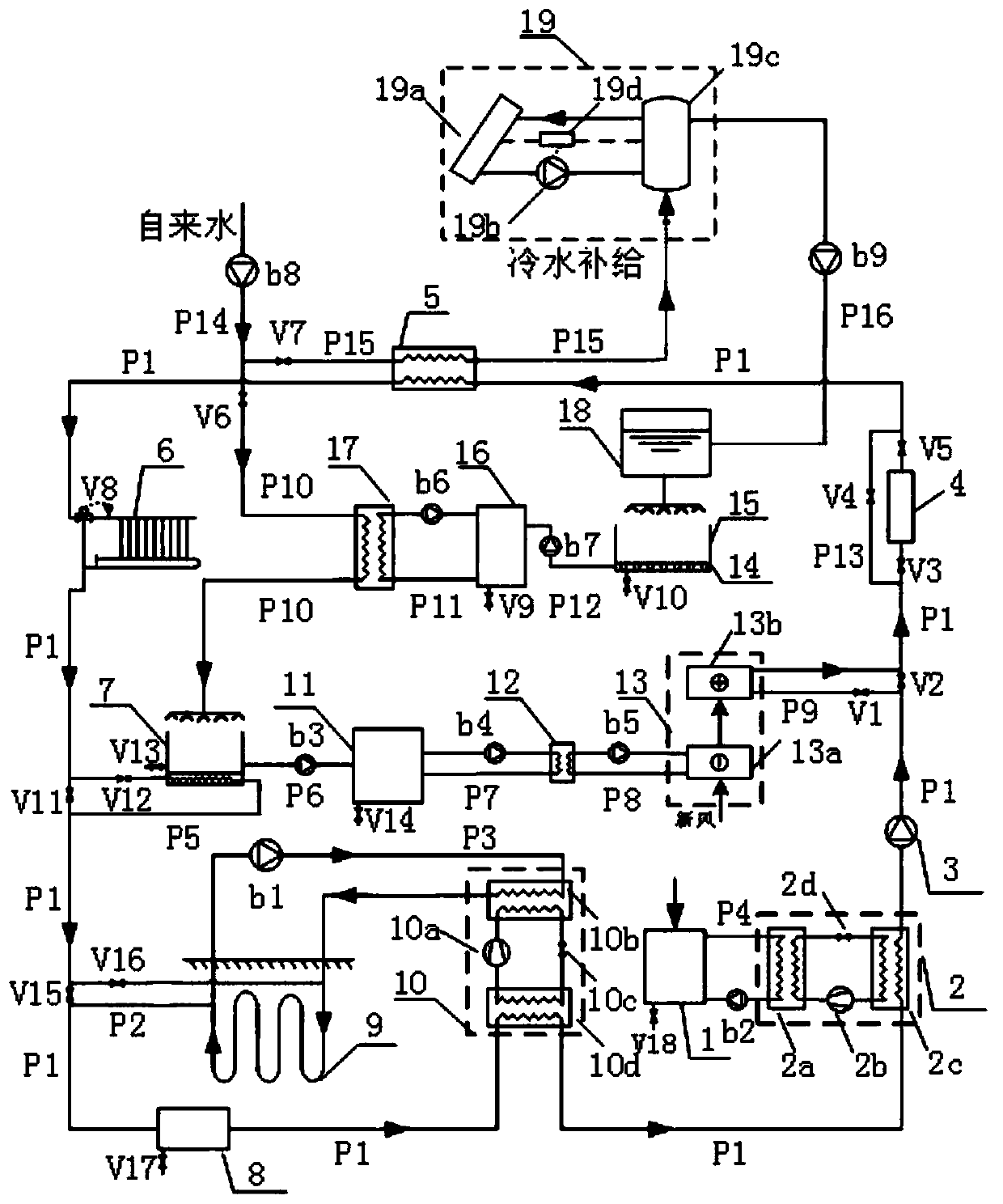

Multi-heat source complementary multi-purpose ice field condensation waste heat cascade utilization system

A multi-heat source, multi-purpose technology, applied in heating systems, heat recovery systems, solar heating systems, etc., can solve the problem of insufficient utilization of condensation waste heat, and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] Such as figure 1 As shown, this embodiment discloses a multi-purpose ice rink condensation waste heat cascade utilization system with complementary multi-heat sources, including the waste heat recovery water tank 1 of the refrigeration unit and the main circulating water pipeline P1. The bottom of the waste heat recovery water tank 1 of the refrigeration unit is provided with a second Six drain valves V18, excess water can be discharged from the sixth drain valve V18, and the circulating water main pipeline P1 is sequentially provided with compression heat pump 2, main circulating water pump 3, fresh air dehumidification system, heating system 4, ice rink Bathing system, floor antifreeze system, ice rink ice meltin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap