Double-AGV cooperative carrying control system and method

A control method and deviation technology, applied in the field of intelligent industrial robots, can solve problems involving only

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

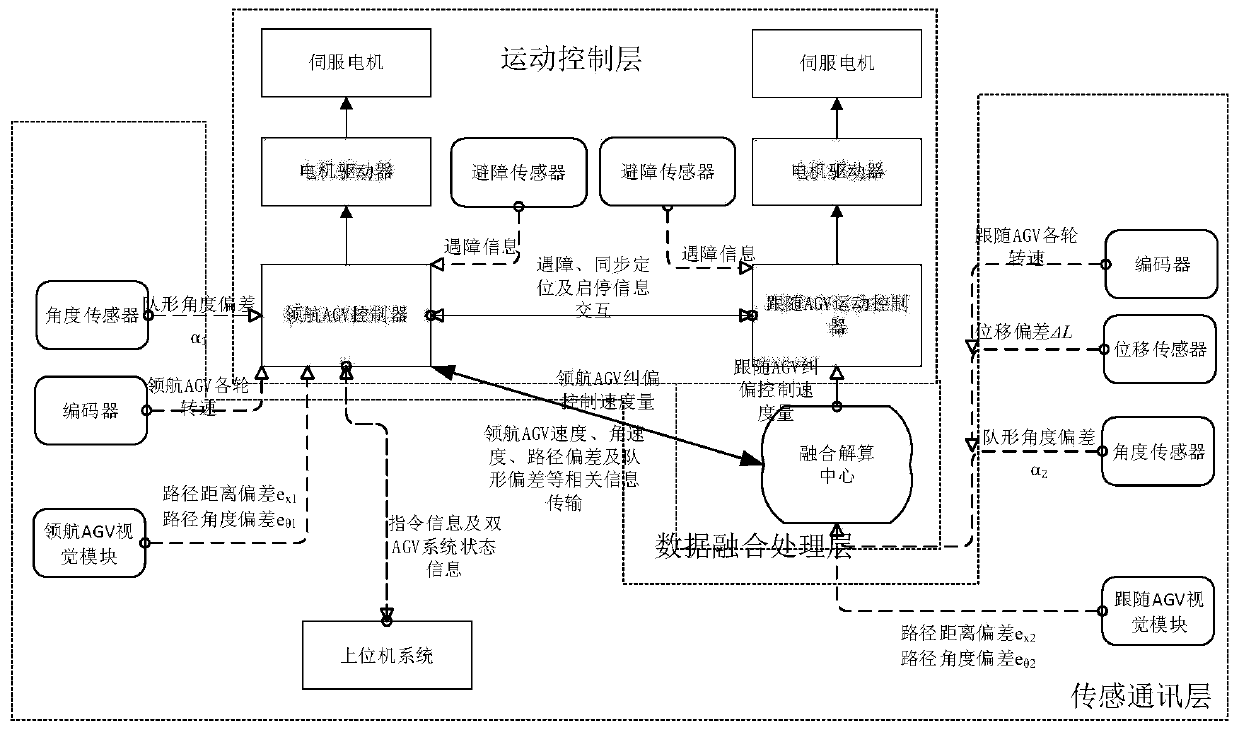

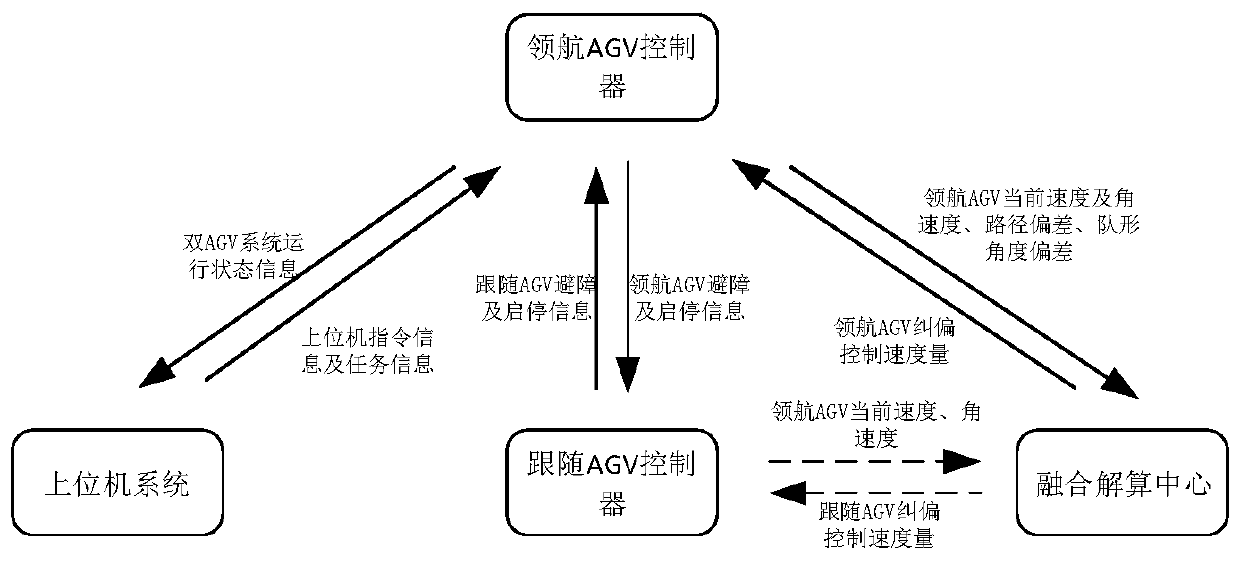

[0047] A dual AGV cooperative carrying control method, which consists of two omni-directional mobile AGV front and rear layouts. On the basis of referring to the existing multi-agent formation control method, a heterogeneous pilot-follow method is adopted, combined with visual guidance path tracking method, constructing a cooperative control model of a three-layer topology structure, and establishing a dual AGV kinematics control model under path tracking and pilot-following based on path deviation and formation deviation, and adopting a rolling predictive control based on time domain The discrete control model optimizes the kinematics control model to realize the stable and reliable cooperative operation of the dual AGV system.

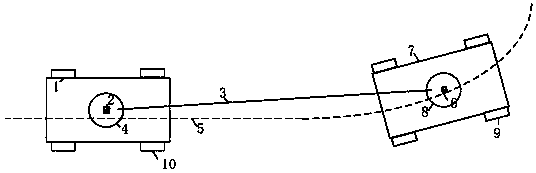

[0048] combined with figure 1 , in the dual AGV cooperative carrying control method described in the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com