Blast furnace coal injection rate data processing method

A technology for data processing and blast furnace coal injection, applied in the field of data processing, can solve the problems of low current signal interference, actuator malfunction, distortion, etc., to achieve the effect of improving accuracy, reducing interference and distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

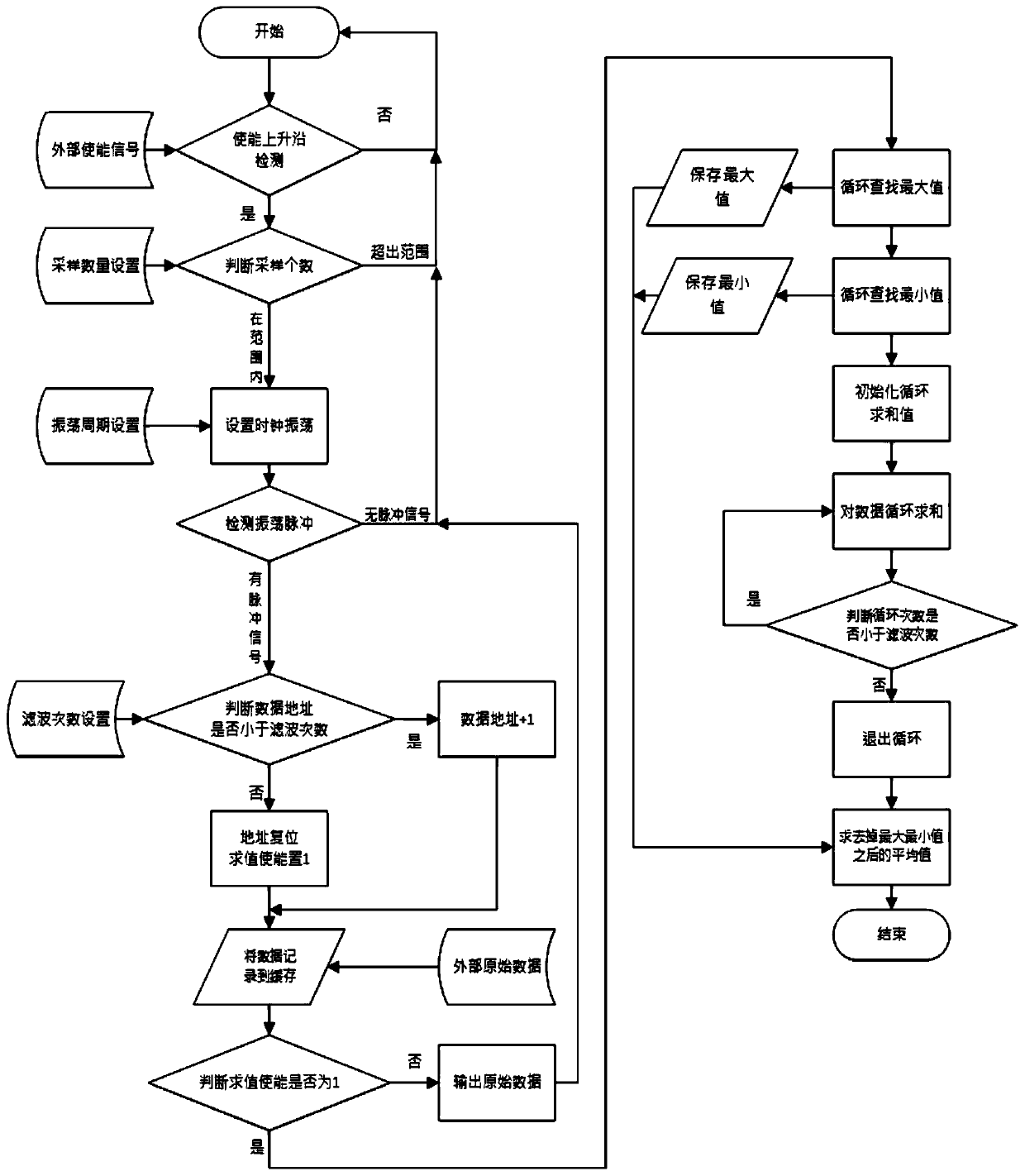

[0028] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0029] Such as figure 1 As shown, a data processing method of blast furnace coal injection rate of the present invention includes the following steps: determine the sampling time t and the amount of sampled data N, collect the amount X of pulverized coal sprayed from the nozzle every time interval t and collect the sampled data Store it, when the amount of stored data reaches N, determine the maximum and minimum values of the N data, then remove the maximum and minimum values, and calculate the average of the remaining N-2 data, as the N data exact value.

[0030] Further, including callable program blocks based on Phoenix programming software PCWork1.86 version, this progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com