NdFeB magnet with high cu and high al and preparation method thereof

A NdFeB magnet technology, applied in magnetic objects, magnetic circuits characterized by magnetic materials, inductor/transformer/magnet manufacturing, etc., can solve the problem of low Hcj, high Cu NdFeB magnets with low mechanical strength, NdFe Problems such as poor mechanical properties of boron magnets, to achieve the effect of ensuring magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

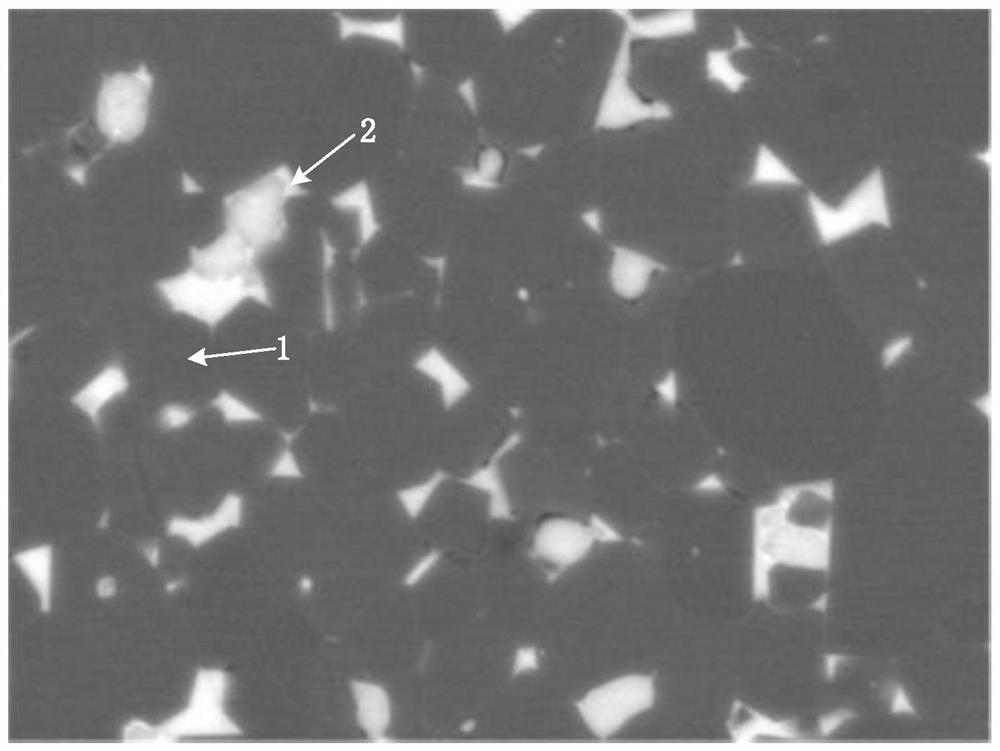

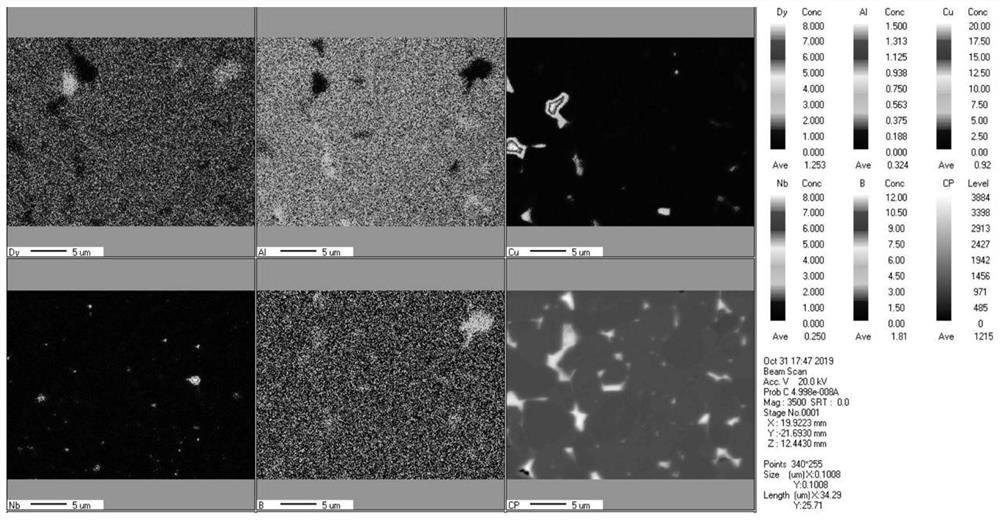

Image

Examples

Embodiment 1

[0080] The preparation method of NdFeB magnet is as follows:

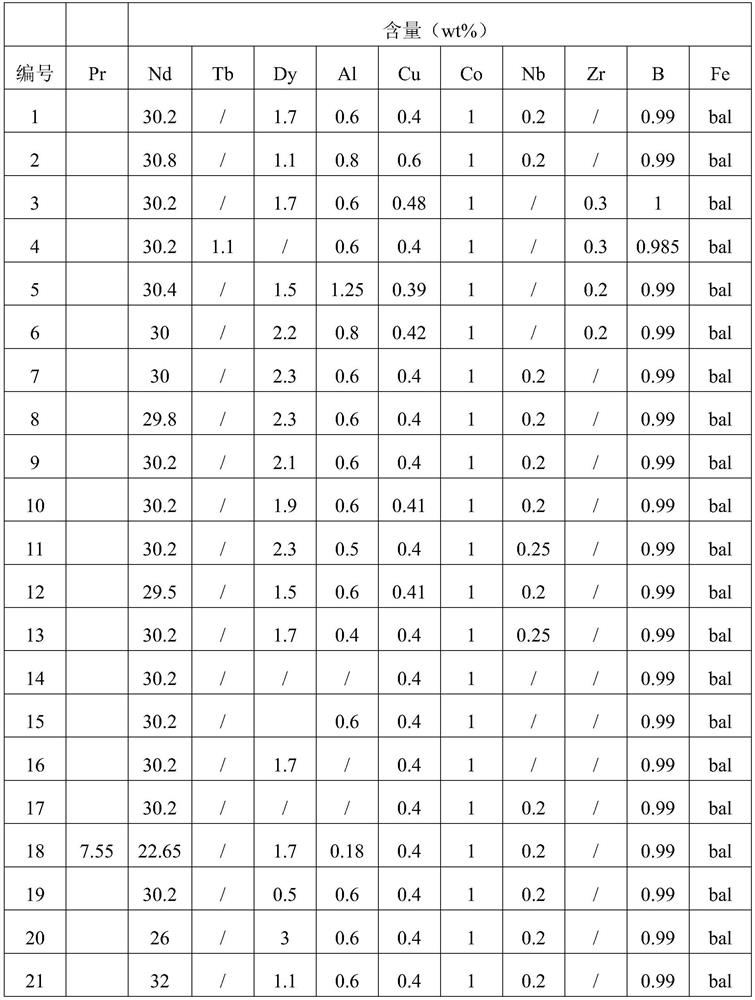

[0081] (1) Smelting: According to the mass percentages of elements in each embodiment and comparative example shown in Table 1, a raw material formula satisfying the mass percentages of the elements is configured. The raw materials are smelted, and a quick-setting casting method is adopted to obtain Nd-Fe-B alloy castings.

[0082] The average thickness of the NdFeB alloy cast sheet is 0.28mm.

[0083] (2) Hydrogen breaking: The hydrogen pressure in the hydrogen adsorption process of the NdFeB alloy cast sheet is 0.081 MPa; the temperature in the dehydrogenation process is 500 ° C to obtain NdFeB powder.

[0084] (3) Jet mill: Send the NdFeB powder into the jet mill for further crushing by the jet mill to obtain fine powder.

[0085] The oxygen content in the mill chamber of the jet mill is below 50ppm.

[0086] The rotating speed of the sorting wheel in the jet mill treatment is 4000rpm / min.

[0087] The parti...

Embodiment 2

[0096] The preparation method of NdFeB magnet is as follows:

[0097] Except the selected raw material formula is different and the average thickness of the NdFeB alloy casting in step (1) smelting is 0.30mm, the parameters in the other preparation process are the same as the preparation process of Example 1.

[0098] The parameters in the preparation process of Comparative Examples 18-21 are the same as those of Example 2 except that the selected raw material formulations are different.

Embodiment 3

[0100] The preparation method of NdFeB magnet is as follows:

[0101] Except that the selected raw material formula is different and the sintering temperature in step (5) sintering is 1040° C., the parameters in the other preparation process are the same as the preparation process of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com