Magnetic flux modulation stator structure using axial sectional hysteresis loop

A technology of magnetic flux modulation and axial segmentation, which is applied to the shape/style/structure of the magnetic circuit, the shape/style/structure of the winding conductor, the magnetic circuit, etc., and can solve the problem of low winding utilization, winding flux leakage, and inability to adapt. problems, to achieve the effect of reducing the aggravation of faults, increasing the adjustment range, and improving the scope and ability of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

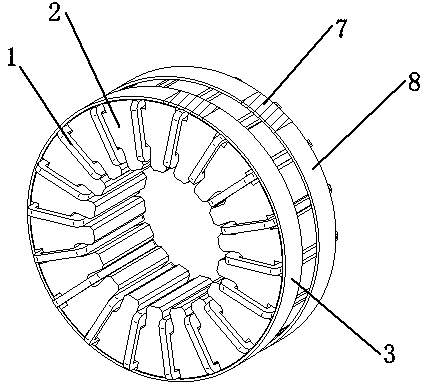

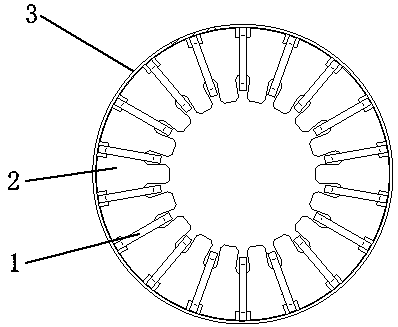

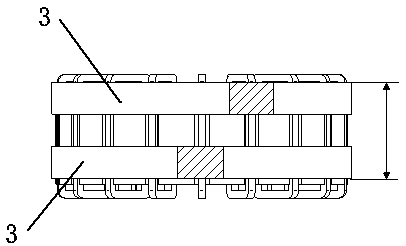

[0050] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a magnetic flux modulation stator structure using an axially segmented hysteresis loop, including a slotted stator 2, m-symmetrical wrap-around windings 1 and a hysteresis loop 3, wherein m is the number of phases of the motor.

[0051] Both sides of the slotted stator 2 are slotted, including a stator yoke 4 , a stator inner slot 5 and a stator outer slot 6 . The number of slots in the stator inner slot 5 is 2pmk, and the slots in the stator inner slot 5 are slotted at equal intervals in the circumferential direction. The stator outer slot 6 is slotted on the back of the stator, the number of the stator outer slot 6 is less than or equal to 2pmk, and the stator outer slot 6 is a radially outward opening structure. Among them, p is the number of pole pairs of the motor, and k is a positive integer.

[0052] The center line of the stator outer slot 6 can be in the same radial direction or form a certain...

Embodiment 2

[0069] Such as Figure 8 As shown, both the present embodiment and the first embodiment adopt a parallel winding method, but the difference between the two lies in that the hysteresis loops 3 are distributed at unequal intervals.

Embodiment 3

[0071] Such as Figure 9 As shown, both the present embodiment and the first embodiment adopt a parallel winding method, but the difference between them is that the back of the slotted stator 2 has hysteresis loops 3 with different axial lengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com