Electronic equipment subrack and assembling method thereof

A technology for electronic equipment and assembly methods, applied in assembly machines, metal processing equipment, printed circuit board sockets, etc., can solve the problems of difficulty in ensuring the assembly accuracy of guide rails, a large number of parts, and a large number of included parts, and achieve light weight and assembly accuracy. High, low part count effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

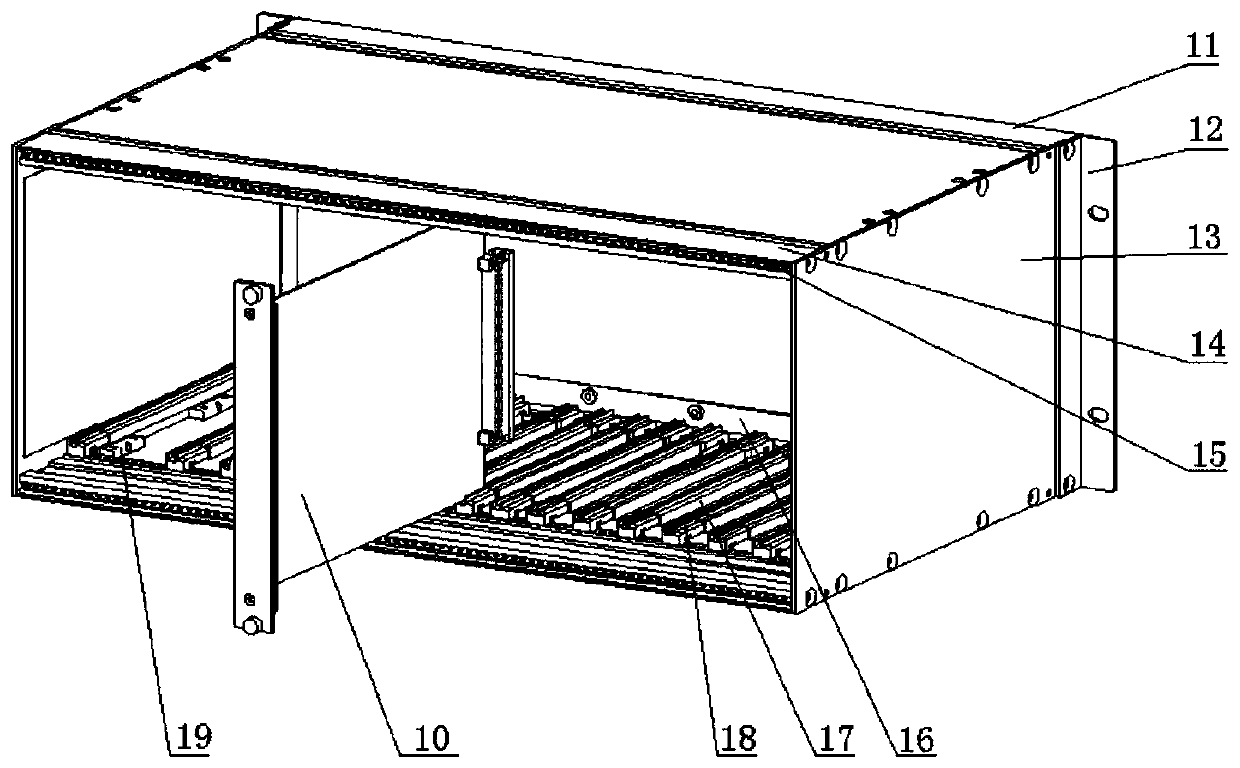

[0024] Such as figure 1 Shown is a schematic diagram of the overall structure of the existing electronic equipment sub-box. Most of the existing electronic equipment sub-boxes that meet the requirements of this standard are figure 1 The structural form shown in includes: front beam 11, side ear 12, side plate 13, rear beam 14, nut bar 15, motherboard mounting beam 16, profile guide rail 17, guide rail head 18, cover plate fixing block 19 and other main Parts, insert the universal board 10 into the profile guide rail 17 to complete the assembly of the equipment. The existing problems are: the number of parts is large; the parts need to be manufactured with molds or profiles; the critical dimension chain contains many parts, and it is difficult to ensure the assembly accuracy of profile guide rails; the assembly is difficult.

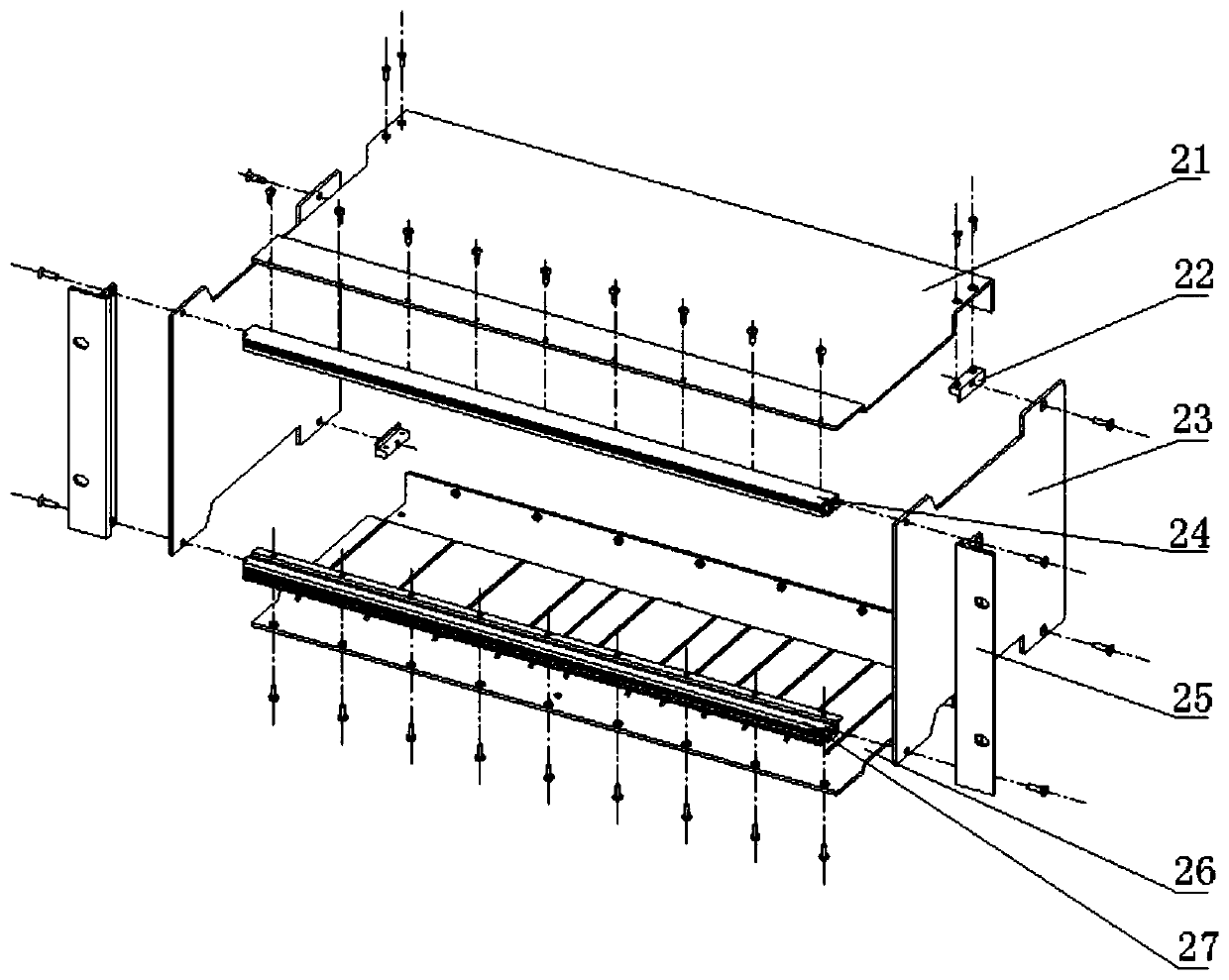

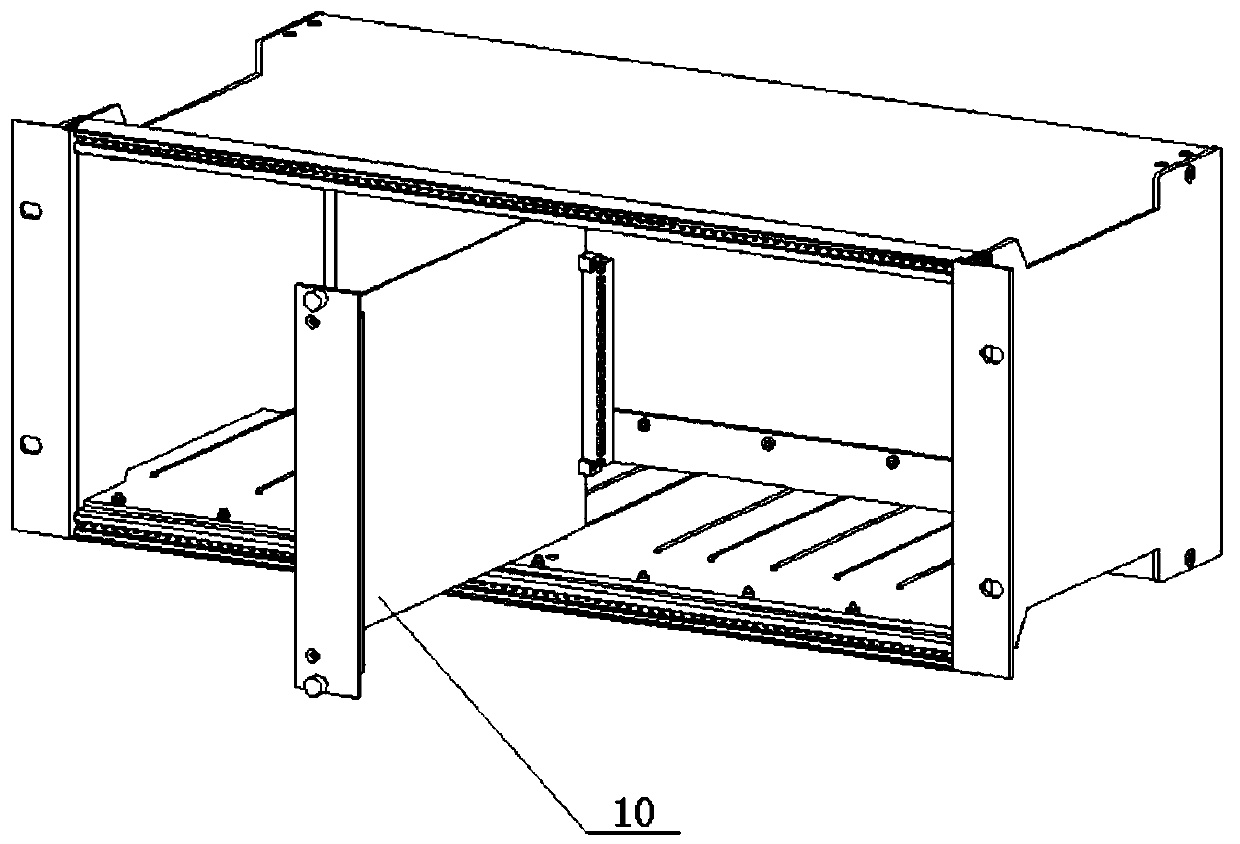

[0025] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com