Multistage wind power type plastic garbage dry-wet separation method

A technology of plastic waste, dry and wet separation, applied in solid separation, chemical instruments and methods, and separation of solids from solids by air flow, etc. The effect of external diffusion and prolonged contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described in conjunction with the following examples.

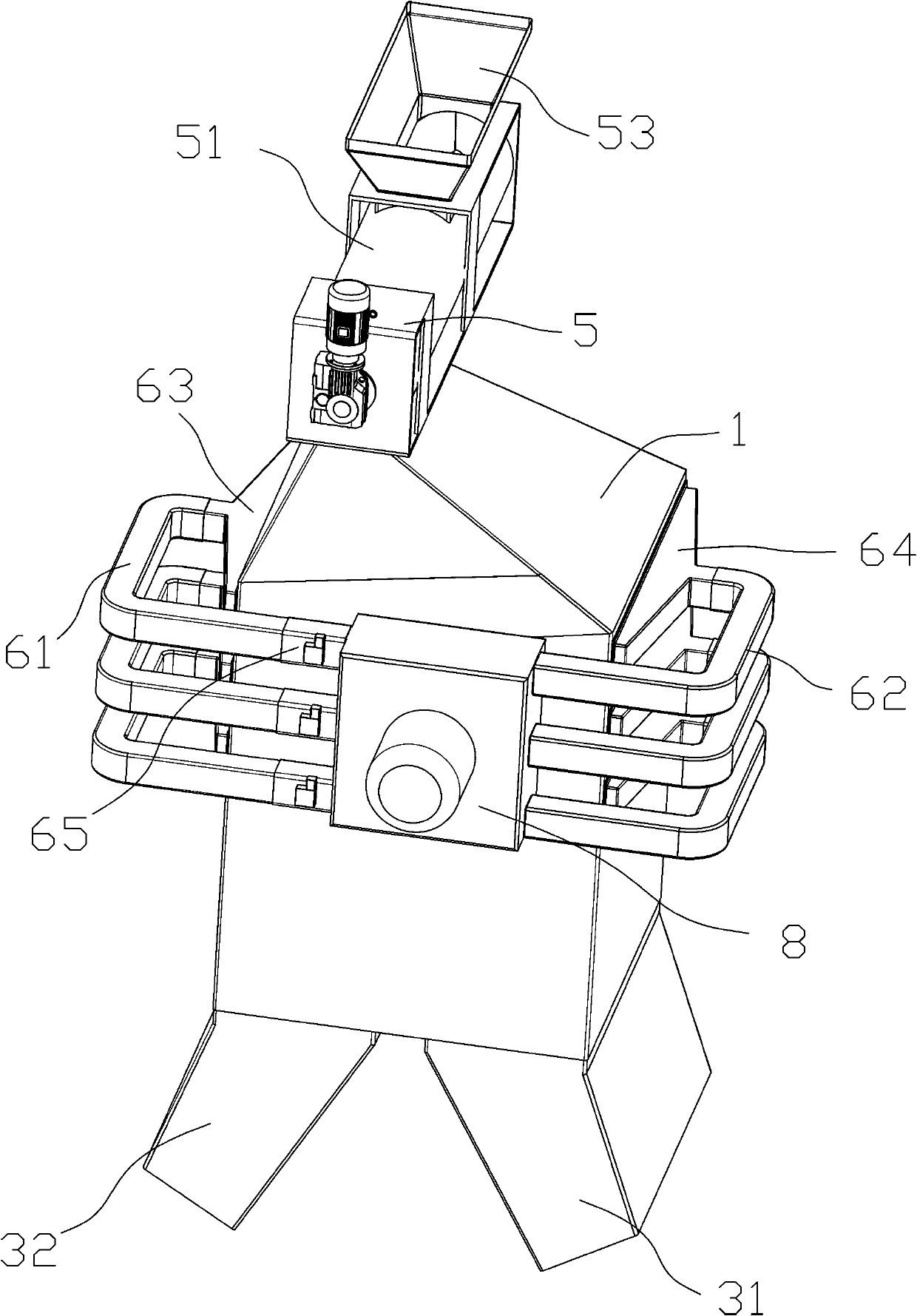

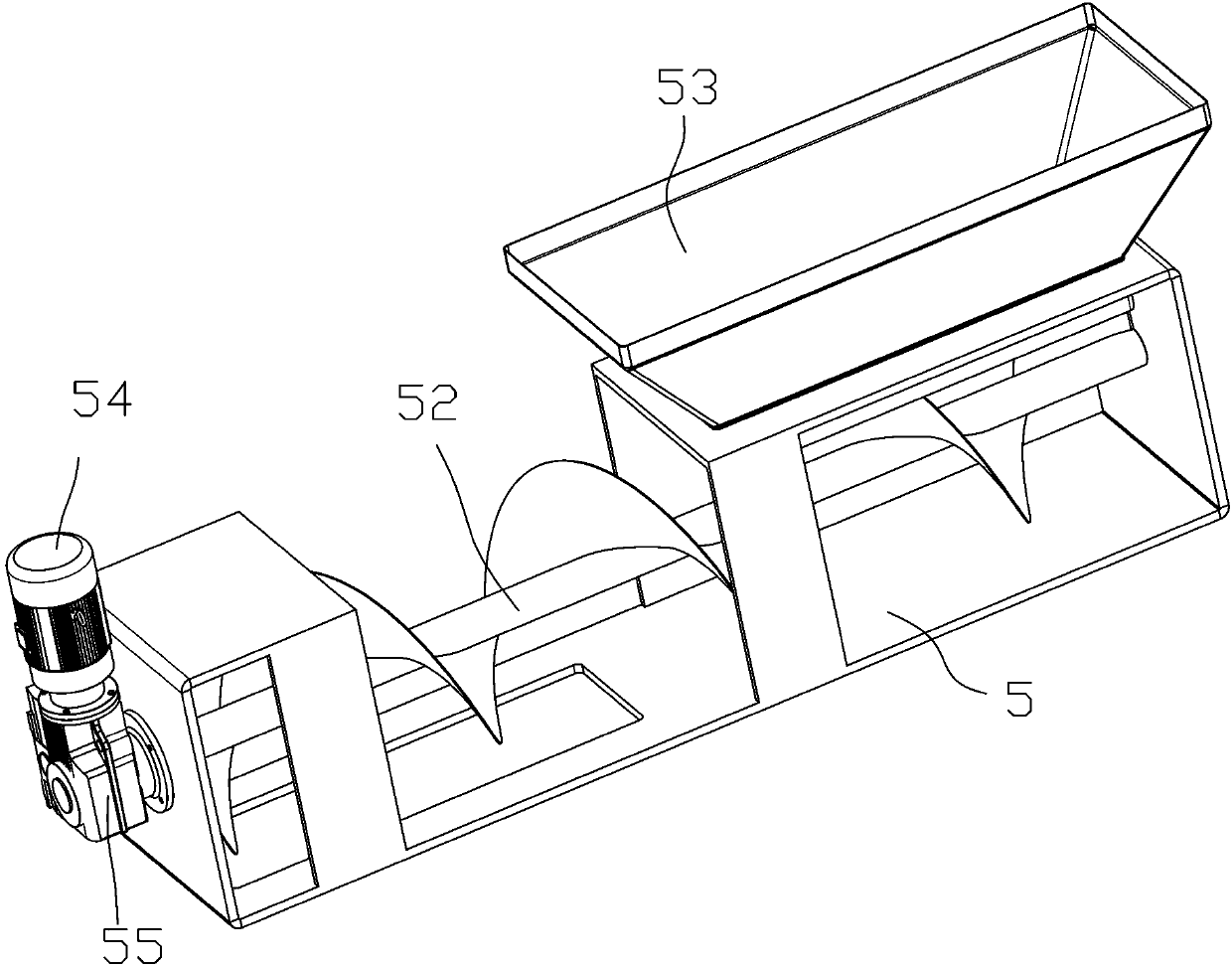

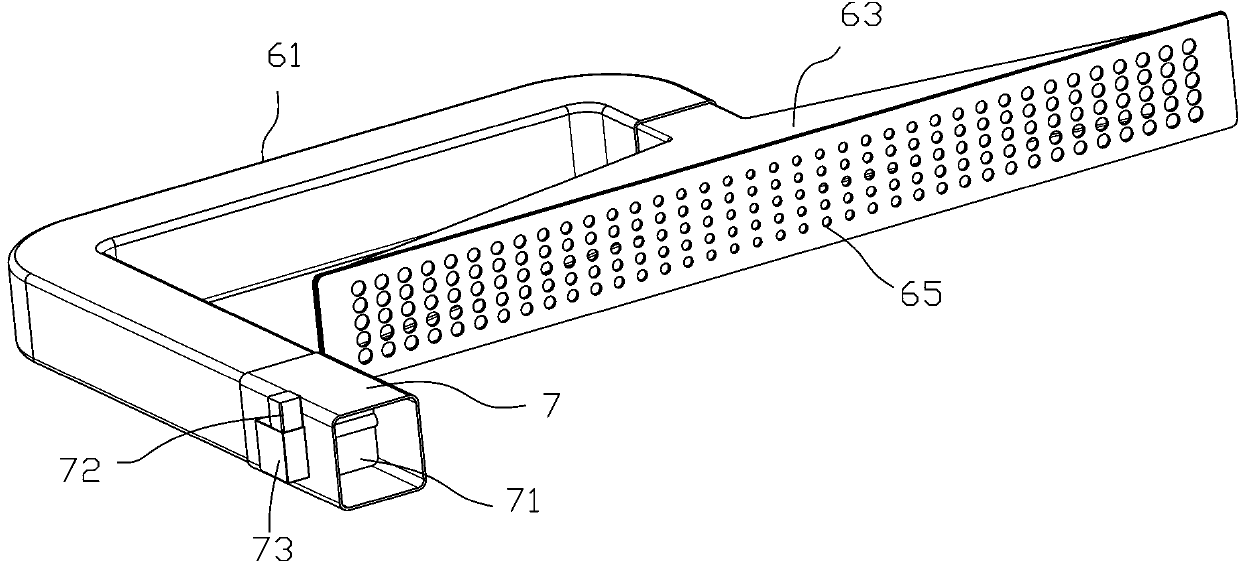

[0023] Depend on Figure 1 to Figure 4 It can be seen that a kind of multi-stage wind type plastic garbage dry-wet separation method described in this embodiment includes a sorting box 1; the top of the sorting box 1 is provided with a feed port 11; the top of the sorting box 1 A screw feeding mechanism connected to the feed port 11 is provided:

[0024] One side of the bottom of the sorting case 1 is provided with a first discharge port 12; the other side of the bottom of the sorting case 1 is provided with a second discharge port 13; A dividing plate 2 is provided between the port 12 and the second discharge port 13;

[0025] One side of the sorting box 1 is sequentially provided with a first air inlet 31, a second air inlet 32 and a third air inlet 33 along the height direction; the other side of the sorting box 1 is sequentially arranged along the height direction A first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com