Energy-saving cold-rolled steel coiled plate alkali liquor cleaning and degreasing equipment and using method thereof

A technology of coil lye and cold-rolled steel, which is applied in the field of cold-rolled steel coil processing, can solve the problems of cleaning effect, affecting the processing process, cleaning dead corners, etc., to ensure the effect of recycling, improve practicability, and ensure smooth sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

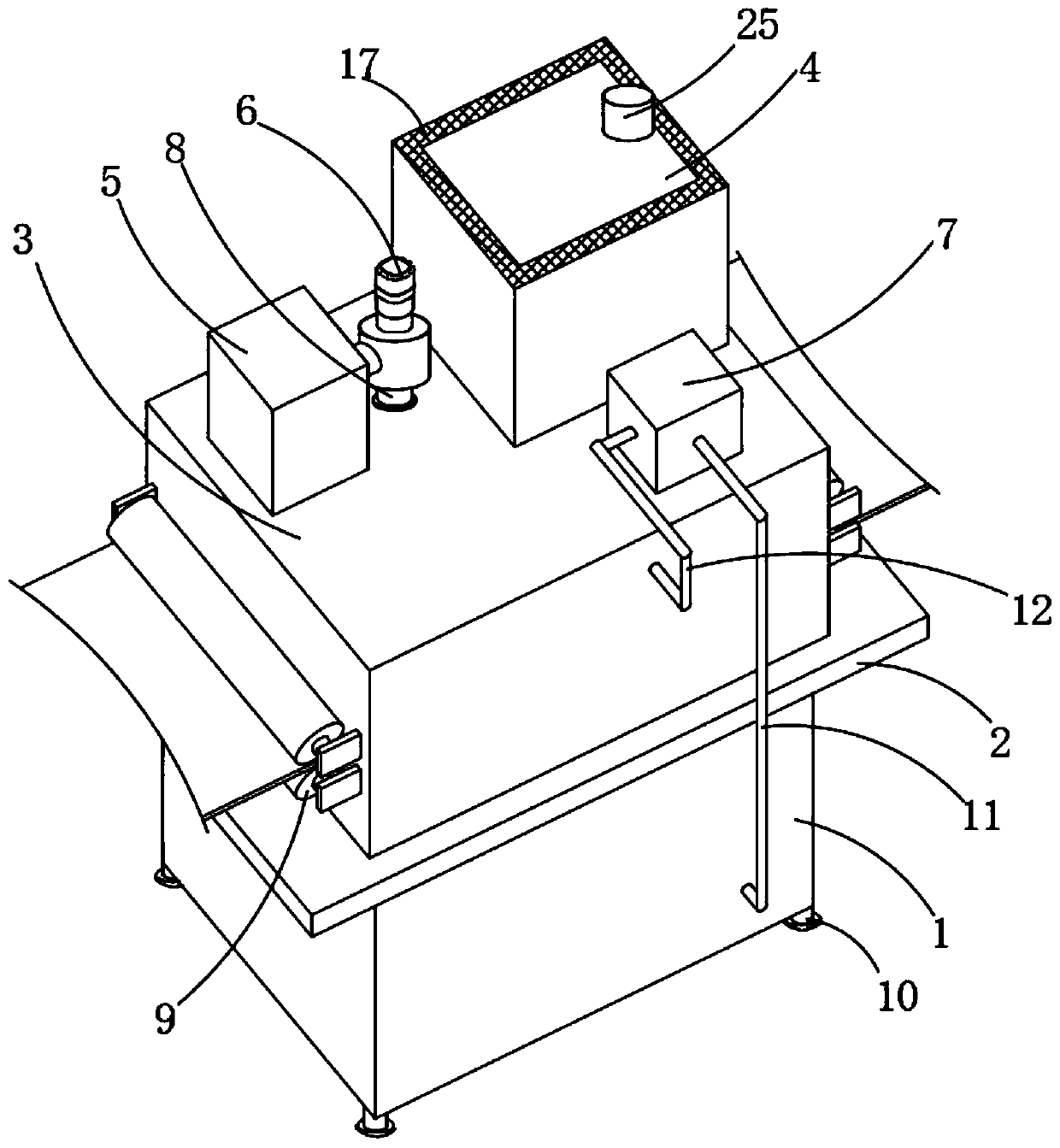

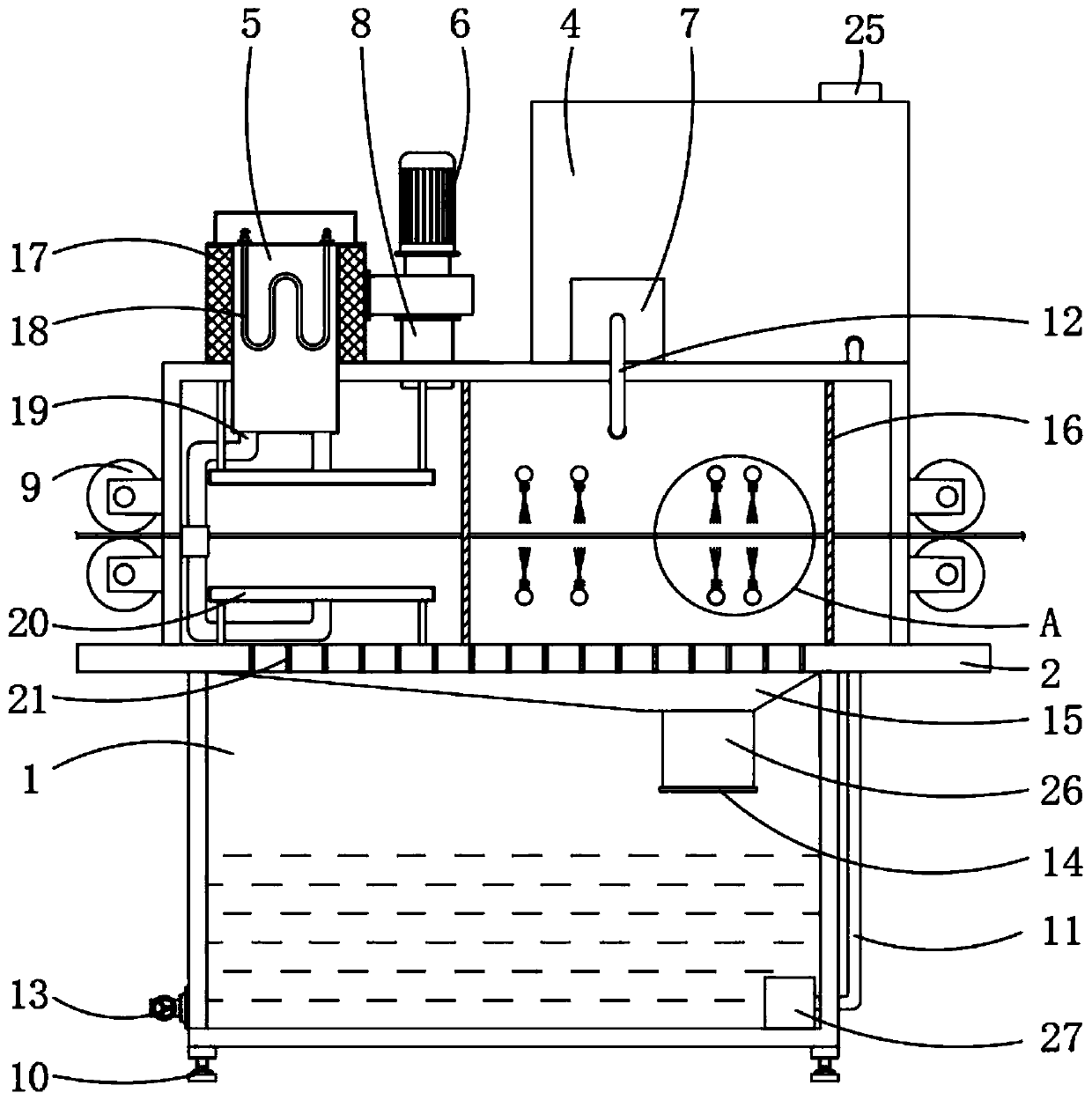

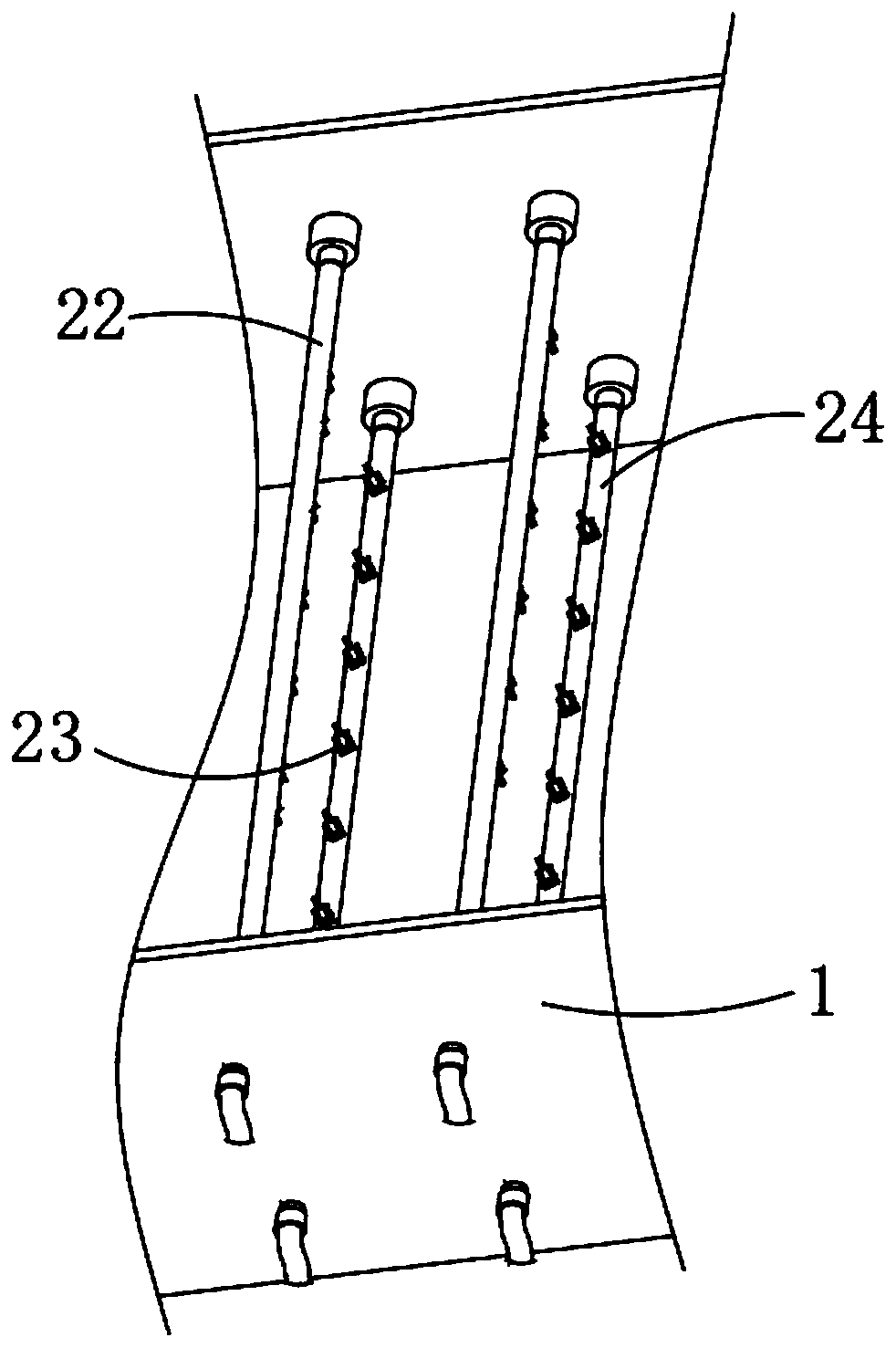

[0029] See Figure 1~4 In the embodiment of the present invention, an energy-saving cold-rolled steel coil lye cleaning and degreasing equipment includes a collecting tank 1 for collecting lye, and the top surface of the collecting tank 1 is an open structure and is fixedly connected with Platen 2, the upper surface of the platen 2 is fixedly connected with a mounting box 3, and the inner two sides of the mounting box 3 are fixedly connected with symmetrically arranged partitions 16, through which the interior of the mounting box 3 is formed from left to right Drying room, cleaning room and empty room. At the same time, both sides of partition 16 and collecting tank 1 are provided with through grooves for cold-rolled steel coils to pass through, so that cold-rolled steel coils can be self-contained from collecting tank 1. The right side enters the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com