Laser cutting machine

A laser cutting machine and frame technology, which is applied in laser welding equipment, abrasive jet machine tools, used abrasive processing devices, etc., can solve the problems of difficult cleaning and easy sticking of waste materials, and achieve the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

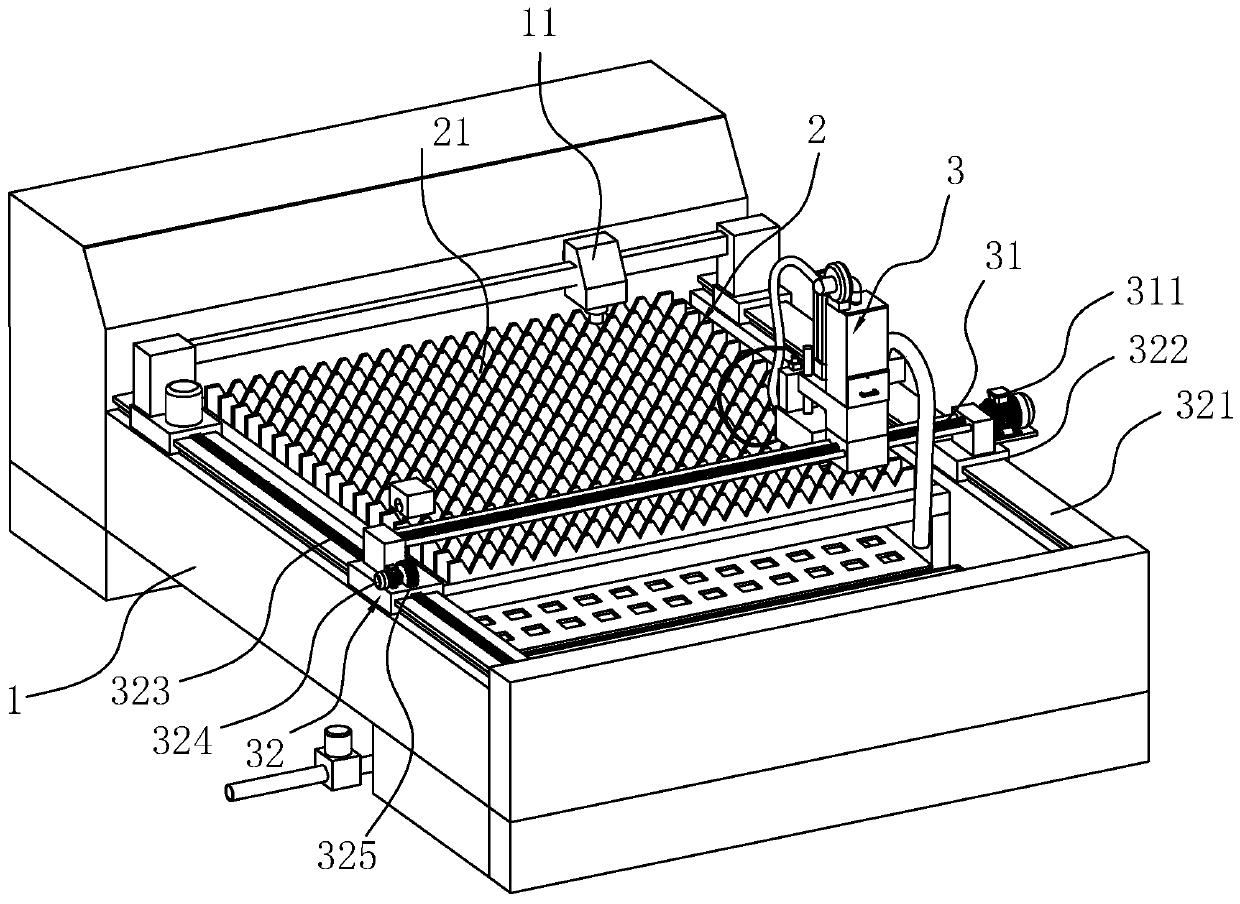

[0037] A laser cutting machine, see figure 1, including a frame 1, the top of the frame 1 is fixed with a horizontally placed support platform 2, and the support platform 2 is evenly fixed with a plurality of support plates 21 along the length direction of the frame 1, and a plurality of support plates 21 are formed between adjacent support plates 21. The gap, the top of the support plate 21 is tooth-like, the top of the frame 1 is horizontally slidably connected to the laser gun 11, and the top of the support platform 2 is provided with a cleaning mechanism 3 for cleaning the waste pasted on the support plate 21.

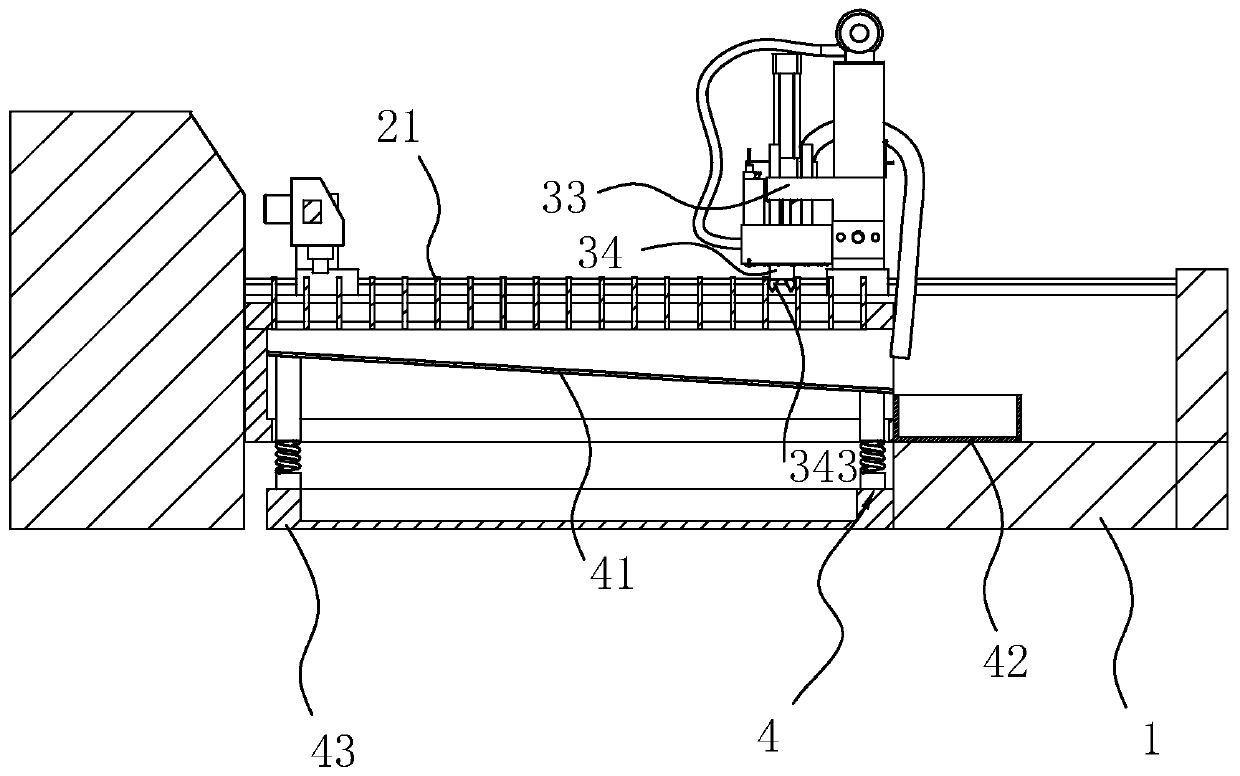

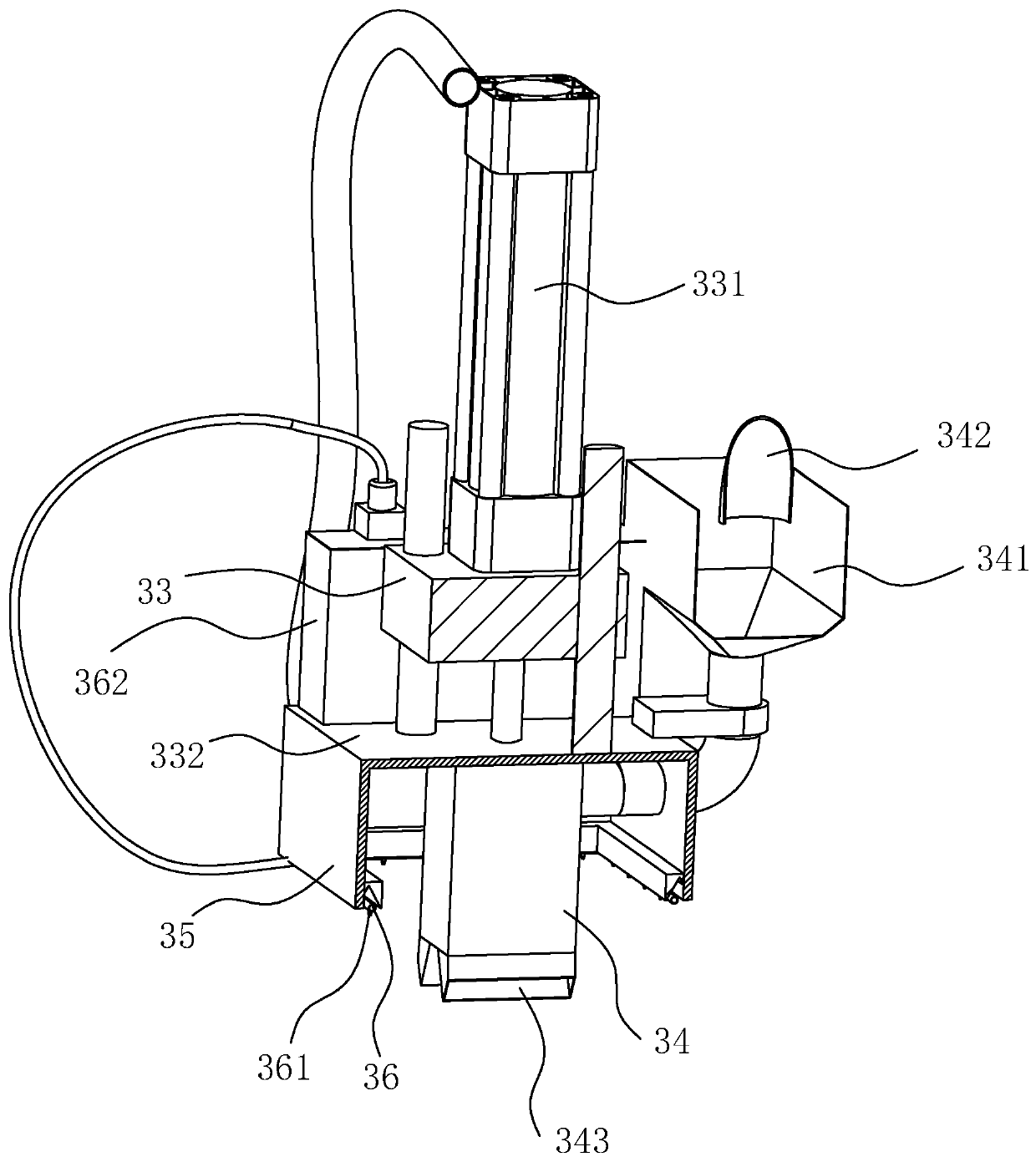

[0038] see figure 1 and figure 2 The cleaning mechanism 3 includes a screw rod 31 horizontally slidably connected to the top of the frame 1. The axial direction of the screw rod 31 is parallel to the extension direction of the support plate 21. Sliding drive assembly 32 . The driving assembly 32 includes a sliding plate 322 fixed on both ends of the screw rod 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap