High-transmittance high-definition anti-explosion polyester film and preparation method thereof

A polyester film and clear technology, applied in the field of polyester film, can solve the problems of high strength of polyester film, good anti-ultraviolet effect, poor anti-ultraviolet effect, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

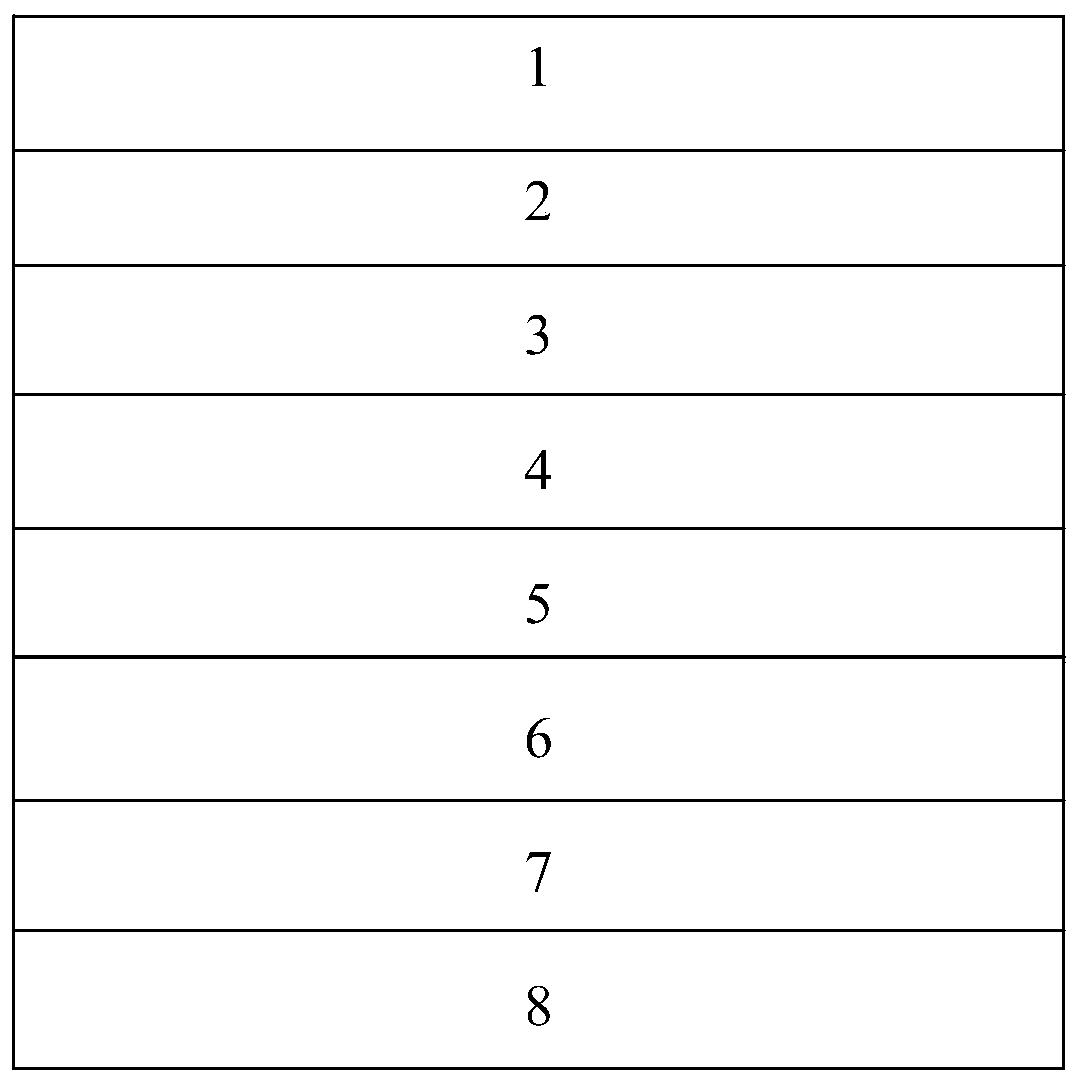

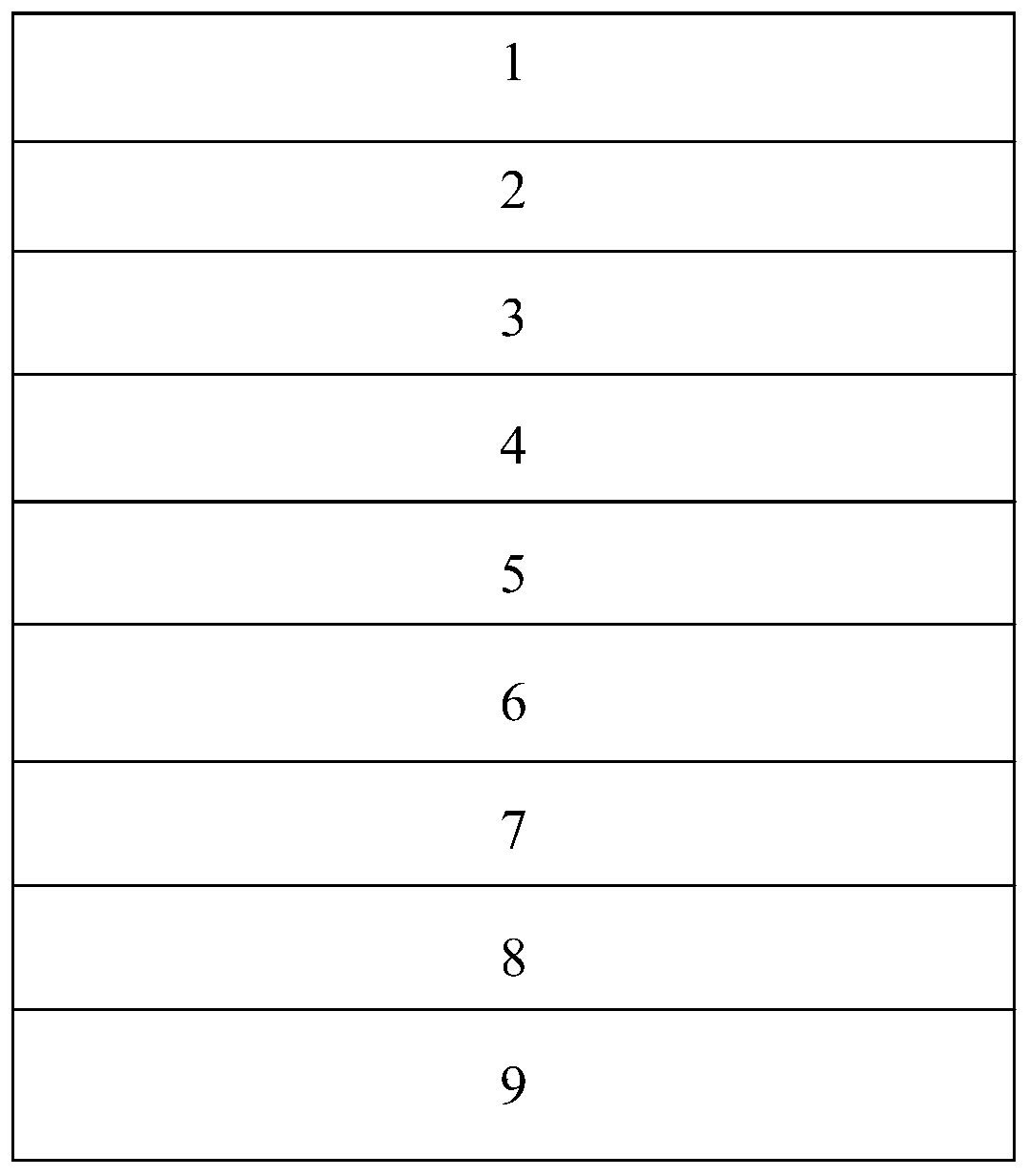

[0066] Such as figure 1 As shown, the present invention provides a high-transmittance and high-definition anti-explosion polyester film, which comprises a coating layer 1, a first functional layer 2, a core layer 3, a second functional layer 4, and a metal heat insulation layer in sequence. 5. Adhesive layer 6, PET base film layer 7, and adhesive layer 8.

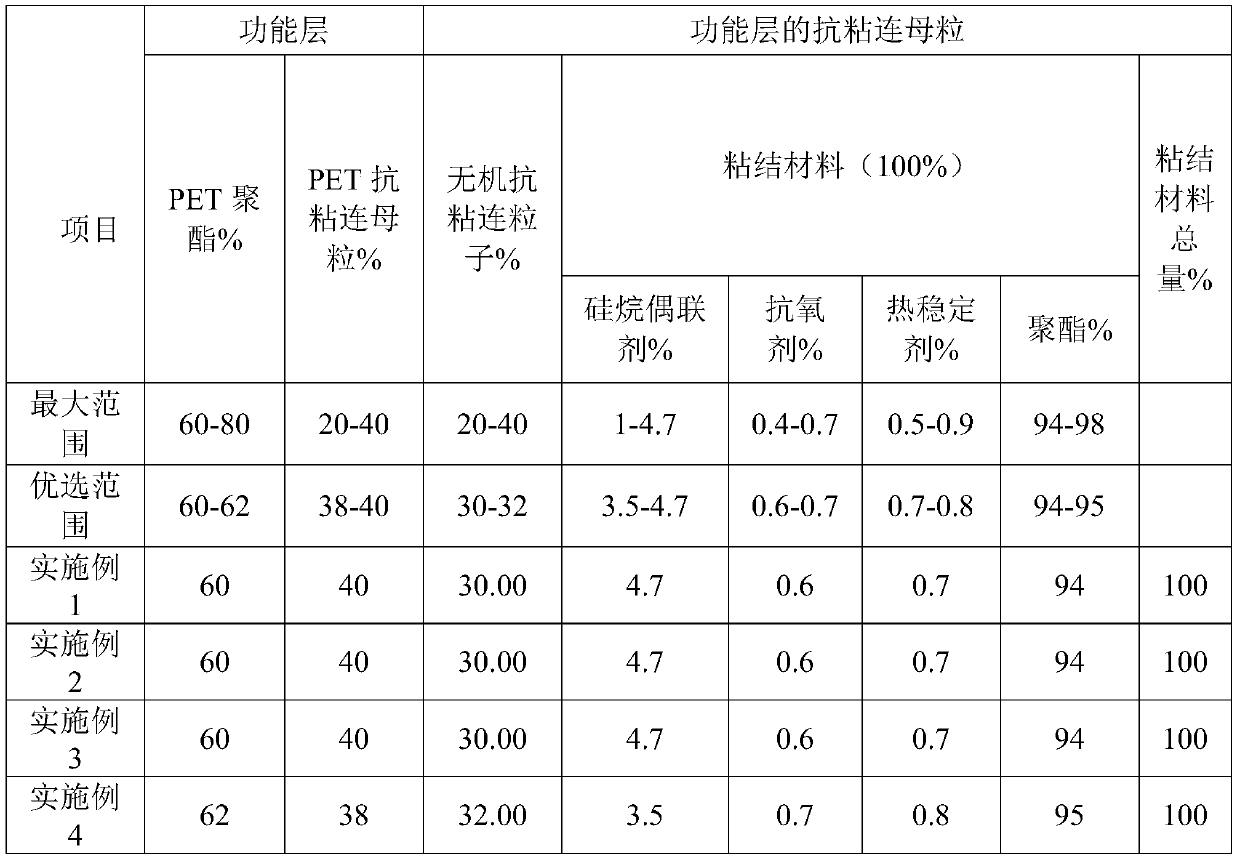

[0067] The core layer includes 98.8% PET polyester, 1.2% heat-insulating and anti-ultraviolet functional masterbatch; the first functional layer and the second functional layer are collectively referred to as functional layers, and the functional layer includes 60% PET polyester, 40% % PET anti-blocking masterbatch.

[0068] The anti-blocking master batch in the functional layer includes silicon dioxide inorganic anti-blocking particles and bonding material; the bonding material includes 4.7% of silane coupling agent, 0.6% of antioxidant, 0.7% of heat stabilizer, and PET The polyester is 94%; the total amount of the silan...

Embodiment 2

[0078] As the high-transparency high-definition anti-explosion polyester film provided in Example 1, wherein, the core layer includes 98.7% PET polyester, 1.3% heat-insulating and anti-ultraviolet functional masterbatch; the first functional layer includes: 60% PET polyester, 40% PET anti-blocking masterbatch.

Embodiment 3

[0080] As the high-transparency high-definition anti-explosion polyester film provided in Example 1, wherein, the core layer includes 98.6% PET polyester, 1.4% heat-insulating and anti-ultraviolet functional masterbatch; the first functional layer includes 60% PET polyester, 40% PET anti-blocking masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com