Drying, dewatering and impurity removing integrated device for fabric after finishing

A post-drying and fabric technology, which is applied in the processing of textile material equipment configuration, textile material processing, and textile material carrier processing. It can solve the problems of cumbersome processing procedures, increase the workload of workers, and single functions, so as to improve smoothness. And regularity, convenient for further processing, and improve the effect of drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

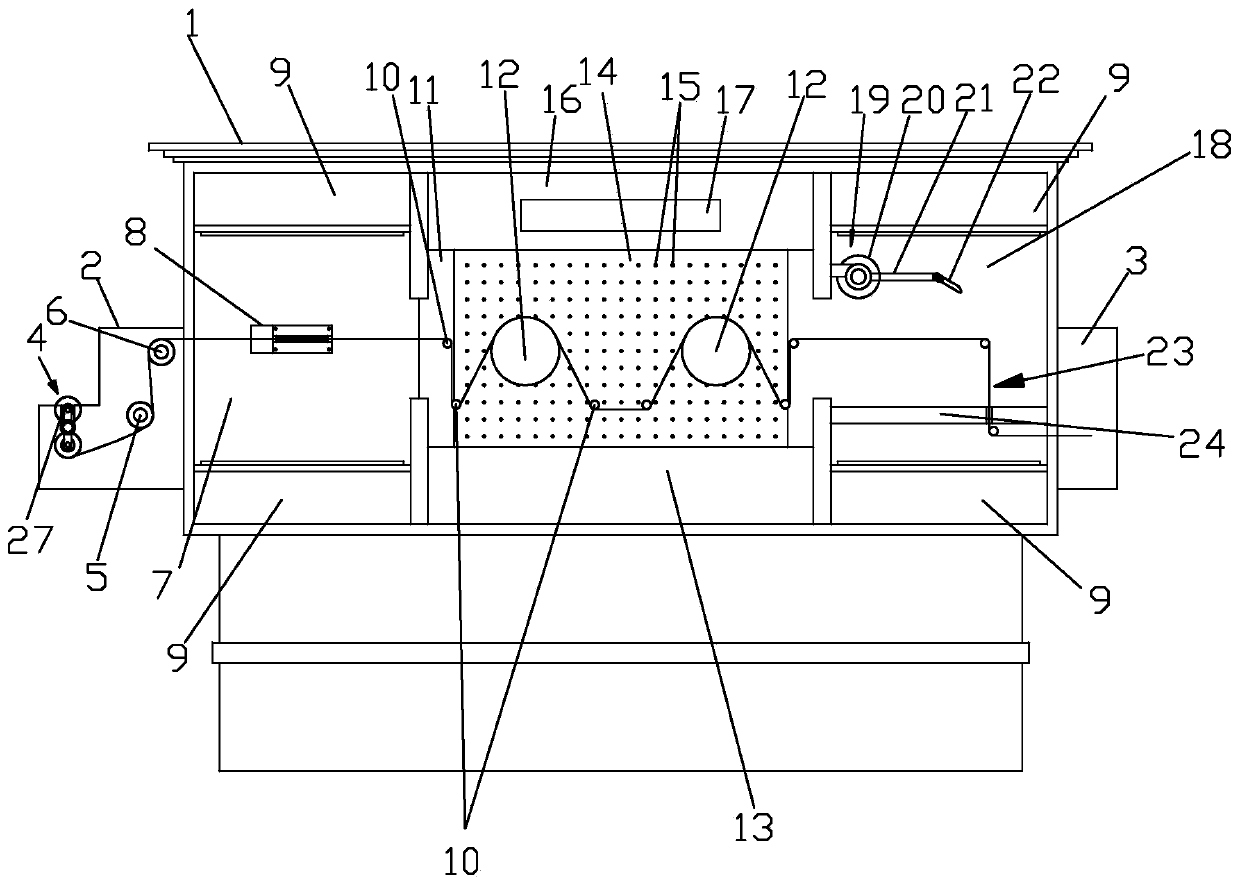

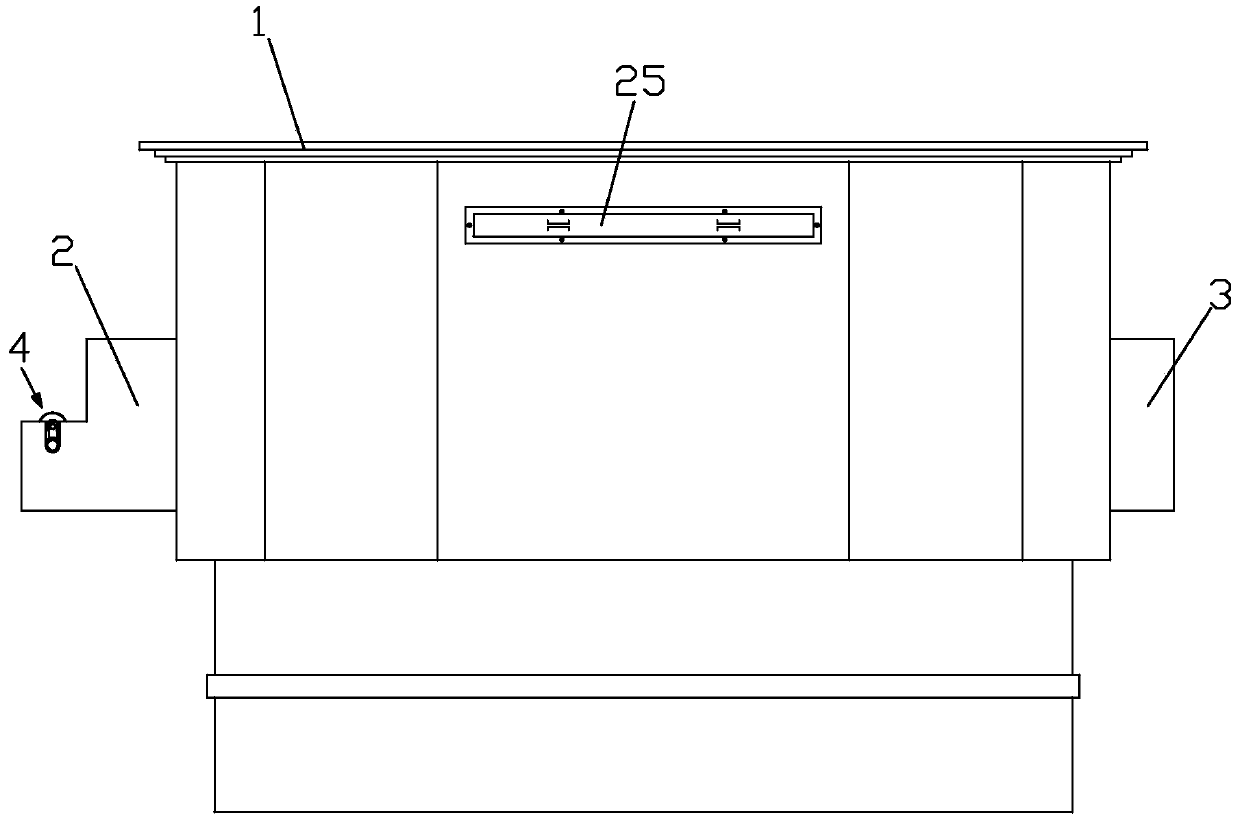

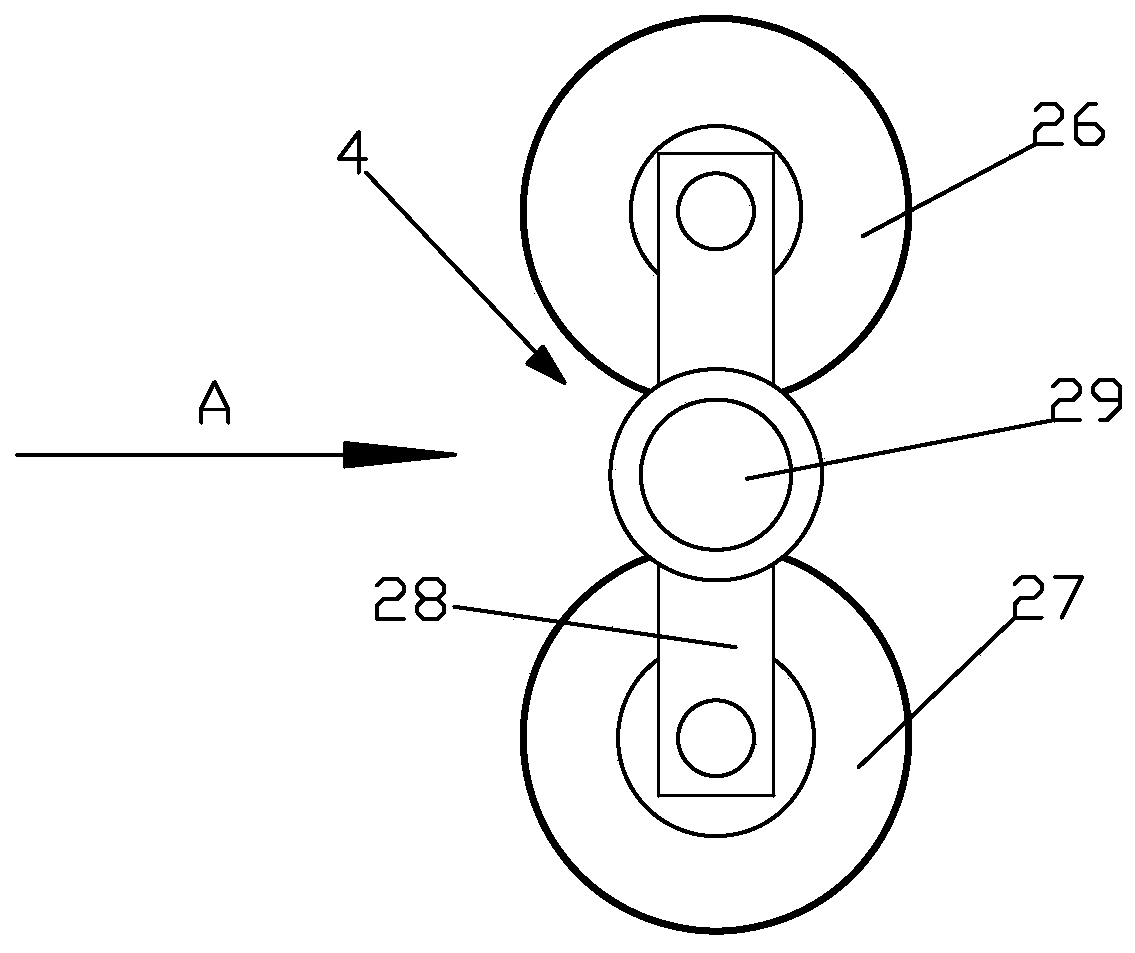

[0035] Such as Figure 1 to Figure 11As shown, an integrated equipment for drying, dehydrating and impurity removal after finishing fabrics, including a chassis 1, a cloth feeding frame 2 and a cloth discharging frame 3, the cloth feeding frame 2 is installed on the left side of the cabinet 1, and the cloth discharging frame is installed on the right side of the cabinet 1 frame 3, the fabric enters from the cloth inlet frame 2, and is exported from the cloth outlet frame 3 after going through the chassis 1. A cloth feeding guide roller 10 and a heating assembly 9 are arranged inside the cabinet 1, the cloth feeding guide roller 10 is used for conveying fabrics, and the heating assembly 9 heats the entire inner cavity of the cabinet 1 to achieve the purpose of drying. The heating assembly 9 of the present invention is equipped with a corresponding temperature sensor and a constant temperature controller, and the constant temperature in the cabinet 1 is kept constant by means of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com