Dip-to-gentle-dip medium-thickness ore body multi-aperture combined application mining method

A kind of technology with gentle slope and medium thickness, mining method, applied in surface mining, underground mining, special mining, etc., can solve the problems of increasing ore dilution rate, large roof exposed area, high waste hole rate, etc., and achieve stope structure layout The effect of flexibility, reduction of dilution rate, and reduction of construction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

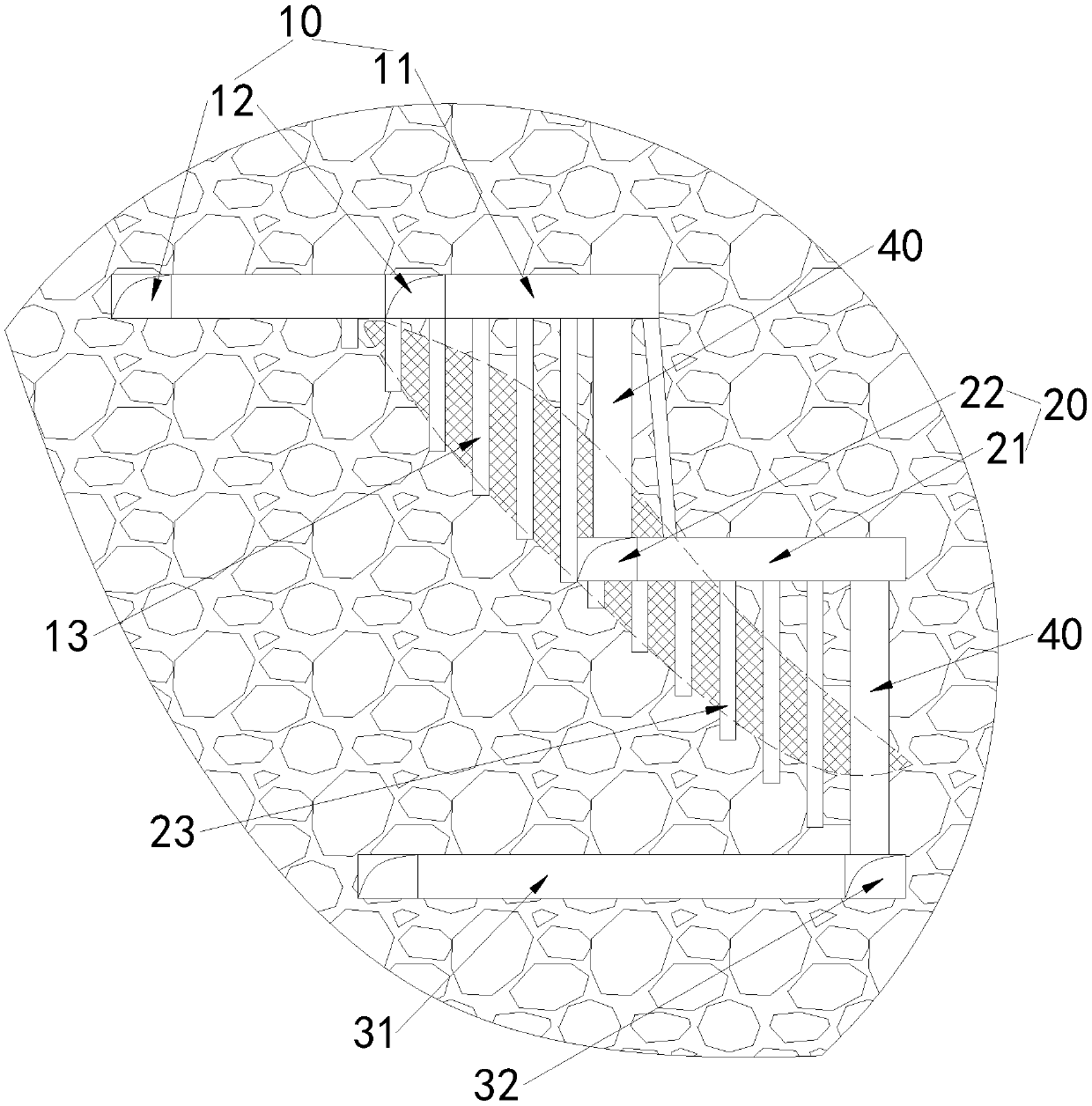

[0028] Such as figure 1 As shown, the present embodiment provides a mining method for combination application of multiple apertures of inclined to gently inclined medium-thick ore bodies, and the method includes the following steps:

[0029] S1 delineated ore body

[0030] The first subsection 10 is constructed from the top rock drilling layer, and the first subsection 10 includes: the first connecting road 11 and the first rock drilling chamber 12; during the construction process of the first subsection 10, geological technicians track the ore body change, adjust the specification and position of the first rock drilling chamber 12 in time; in this embodiment, the section specification of the first rock drilling chamber 12 is set to the specification of the deep hole (aperture φ90mm) rock drilling chamber, that is, 3.6 Meters wide and 3.3 meters high; at the same time, the ore access road 31 and the cutting ditch 32 are constructed at the bottom ore layer, and the ore body of...

Embodiment 2

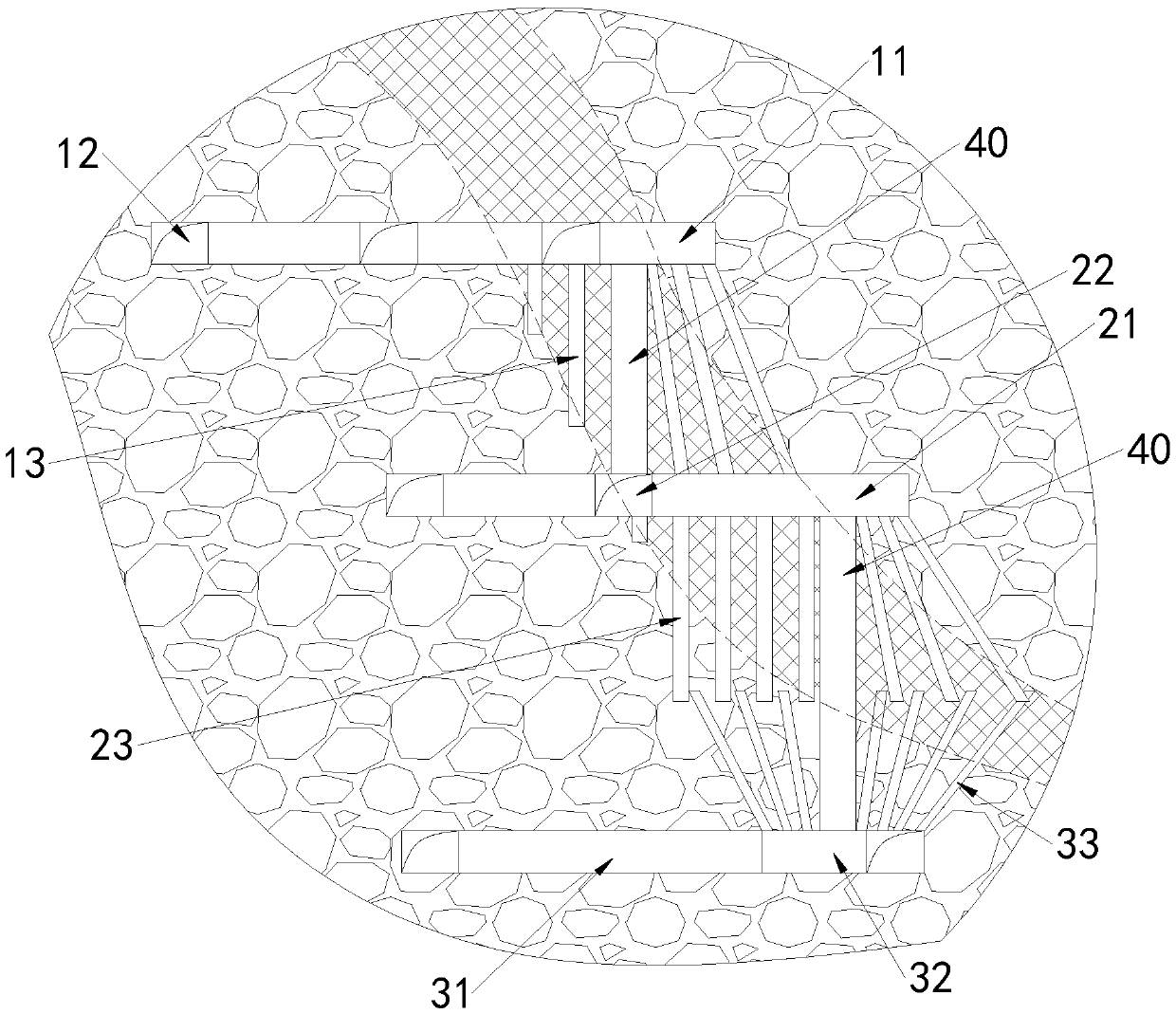

[0043] Such as figure 2 As shown, when the height difference between the second subsection 20 and the trench 32 at the bottom is greater than 30 meters, and the top plate in the trench 32 is stable and does not collapse, a divergent middle hole 33 is constructed upward from the top plate of the trench 32 , the diameter of the middle hole 33 is 65 mm, the middle hole 33 is connected with the second deep hole 23, and the middle hole 33, the second deep hole 23, and the first deep hole 13 are arranged in the order of the medium-thick ore that is inclined to the gentle slope. body for rock drilling and blasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com