Method for ultrasonic nondestructive testing of non-uniform hooping constraint force of concrete-filled square steel tubular column

A technology for concrete-filled steel tube columns and concrete columns, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of low precision, cumbersome testing, and reduced sensitivity, and achieve simple testing devices, The effect of intuitive measurement results and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme of the present invention and the accompanying drawings.

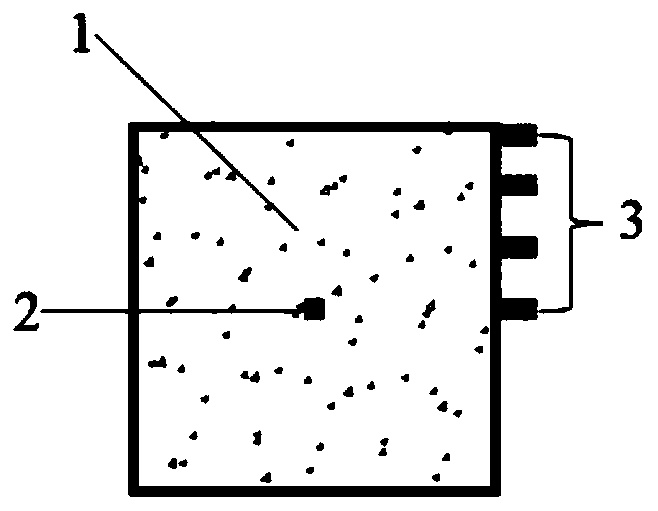

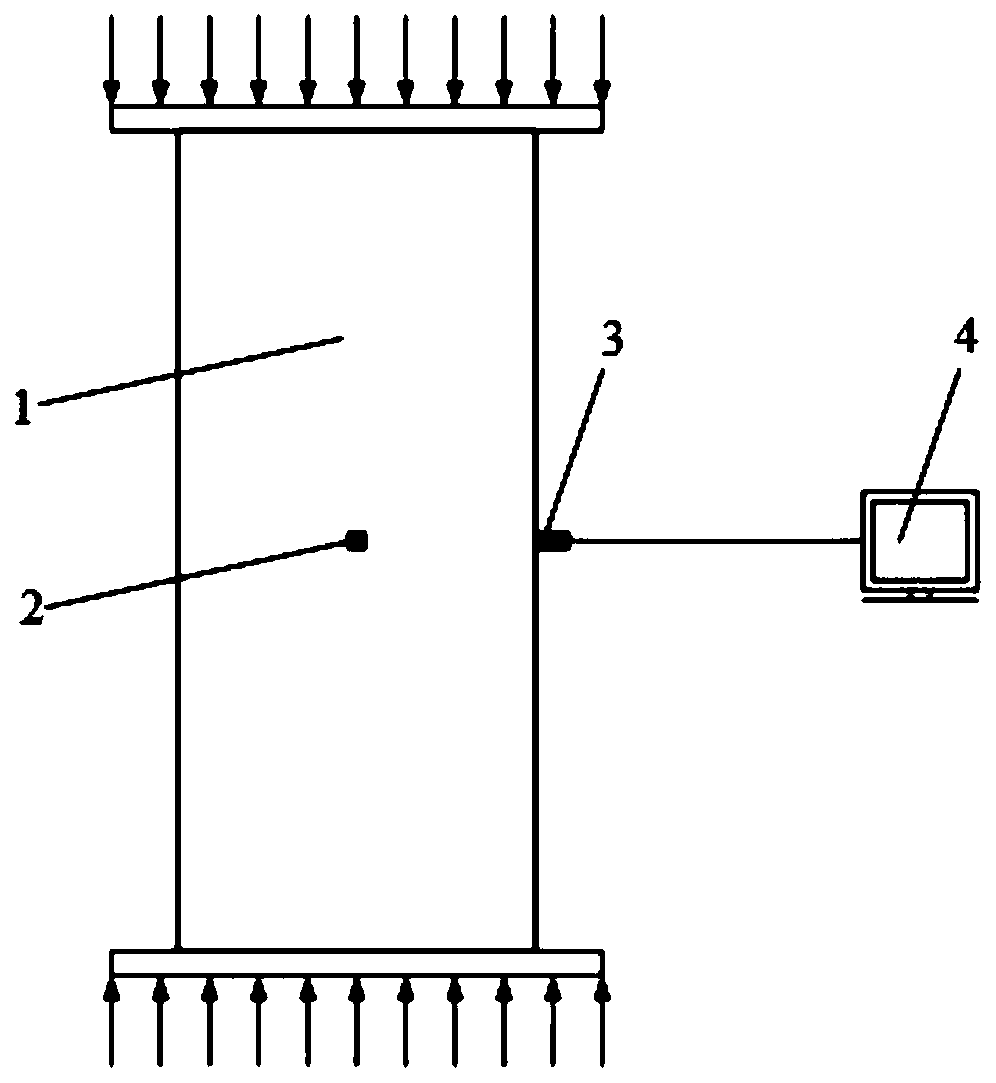

[0023] As shown in the figure, the embodiment of the present invention provides a detection device corresponding to the ultrasonic non-destructive detection method for the uneven hoop binding force of a square steel tube concrete column. The detection device includes a square steel tube concrete column to be tested 1 , an ultrasonic transmitting sensor 2 , a signal amplifier device, a plurality of ultrasonic receiving devices 3 and a computer 4 . Wherein, the square concrete-filled steel tube column 1 to be tested is preferably formed by pouring self-compacting concrete, and the ultrasonic transmitting sensor 2 is embedded in the central position of the required measurement section in the column before the core concrete is poured. The direction is close to the outer surface of the steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com