Detection method for calcitriol soft capsule production equipment cleaning verification

A detection method and production equipment technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as incompatibility, low content of active ingredients, and large damage to instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

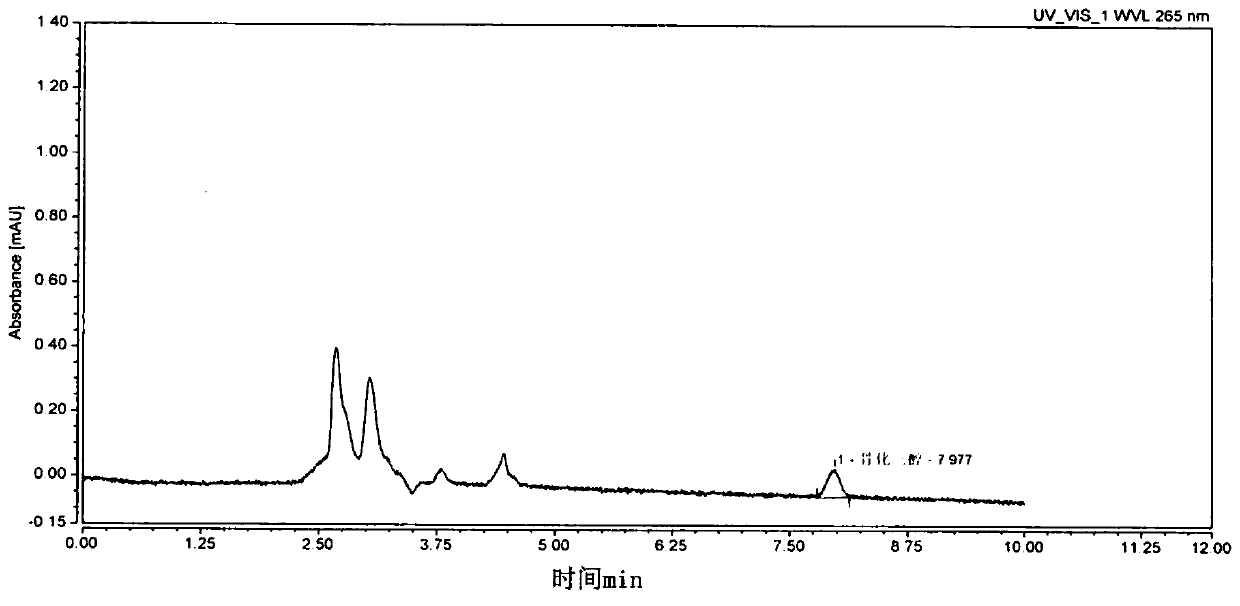

[0041] Prepare the test product according to the preparation process of the test product solution in the scheme, and take 100 μl into the chromatographic system. Chromatographic conditions: Chromatographic column: COSMOSIL 5SL-Ⅱ, 250mm×4.6mm, mobile phase: n-hexane: ethyl acetate: methanol: n-propanol = 60:40:2:1, UV detection wavelength is 265nm, flow rate is 1.2ml / min, column temperature: 30°C.

Embodiment 2

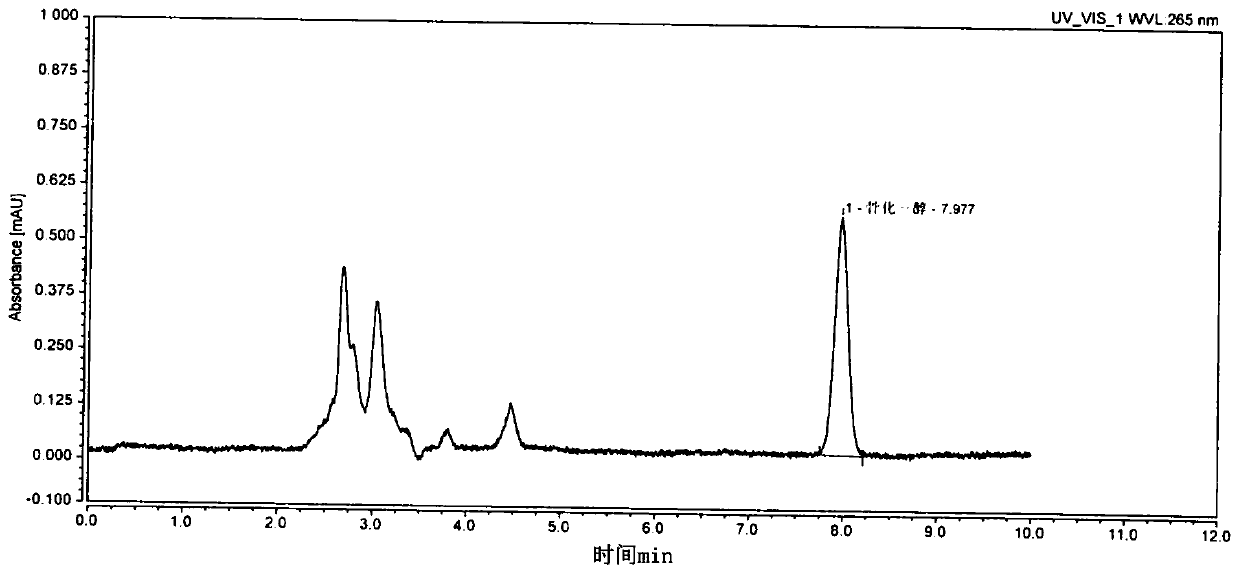

[0043] Prepare the test product according to the preparation process of the test product solution in the scheme, and take 100 μl into the chromatographic system. Chromatographic conditions: Chromatographic column: COSMOSIL 5SL-Ⅱ, 250mm×4.6mm, mobile phase: n-hexane: ethyl acetate: methanol: n-propanol = 60:40:2:1, UV detection wavelength is 267nm, flow rate is 1.2ml / min, column temperature: 30°C.

Embodiment 3

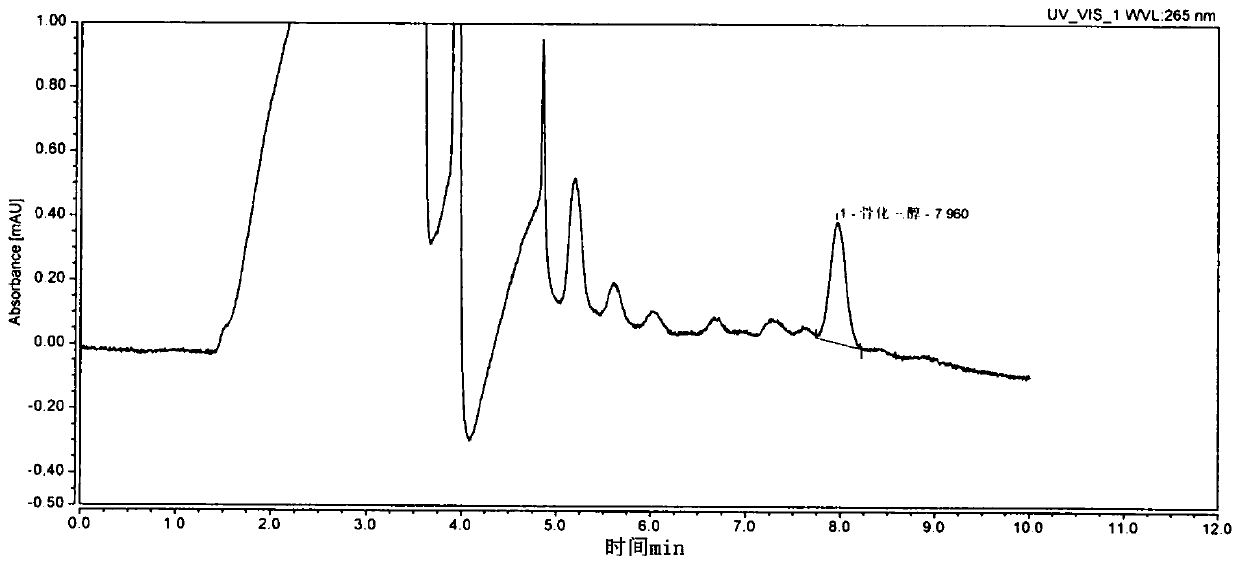

[0045] Prepare the test product according to the preparation process of the test product solution in the scheme, and take 100 μl into the chromatographic system. Chromatographic conditions: Chromatographic column: COSMOSIL 5SL-Ⅱ, 250mm×4.6mm, mobile phase: n-hexane: ethyl acetate: methanol: n-propanol = 60:40:2:1, UV detection wavelength is 263nm, flow rate is 1.2ml / min, column temperature: 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com