A Transformer Winding Deformation Fault Location Detection Method

A transformer winding and fault location technology, which is applied in transformer testing, electric winding testing, electric/magnetic solid deformation measurement, etc., can solve the problem that transformer faults cannot detect winding deformation fault locations, and achieve the effect of preventing power grid accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

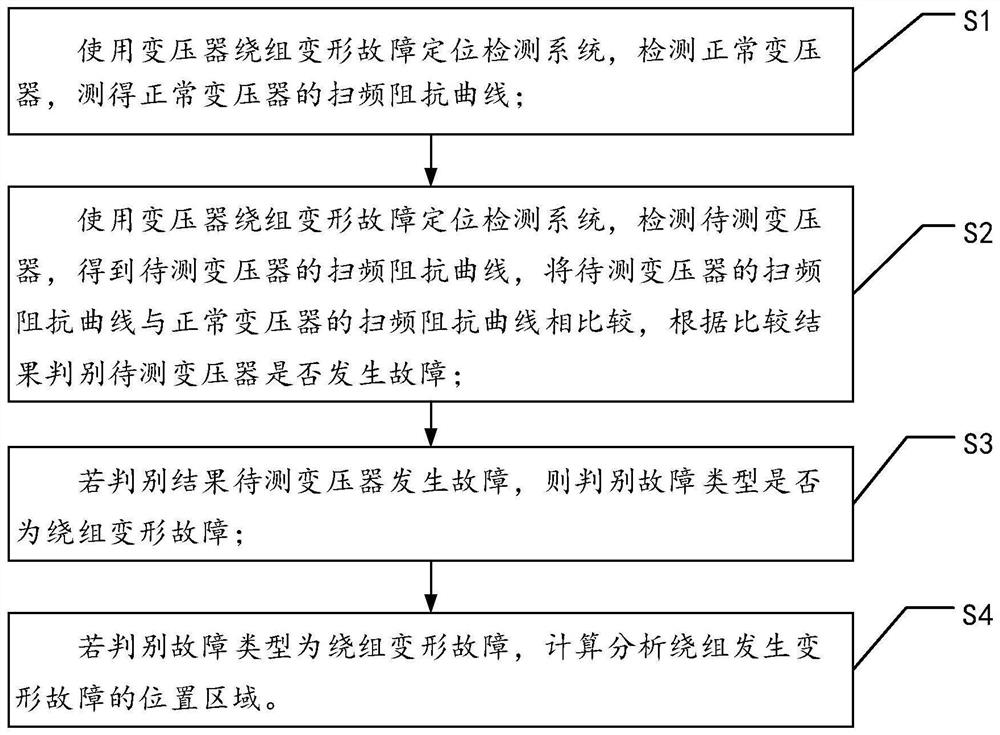

[0041] see figure 1 ,figure 1 It is a method flowchart of a transformer winding deformation fault location detection method provided by an embodiment of the present invention.

[0042] A transformer winding deformation fault location detection method provided by the present invention comprises the following steps:

[0043] Step S1: Short-circuit the winding on one side of the normal transformer, and connect the winding on the other side to the transformer winding deformation fault location detection system, use the transformer winding deformation fault location detection system to detect the normal transformer, and measure the normal transformer in a specific frequency band (10hz-1Mhz) The short-circuit impedance of the normal transformer is drawn according to the frequency change and impedance value;

[0044] Step S2: Use the transformer winding deformation fault location detection system to detect the transformer to be tested, obtain the frequency sweep impedance curve of t...

Embodiment 2

[0063] In this embodiment, it is specifically described how the transformer winding deformation fault location detection system solves the frequency sweep impedance;

[0064] Short-circuit the outgoing line of the high-voltage side or low-voltage side of the transformer, and load the frequency sweep signal at the first end of the non-short-circuit side winding After the signal passes through the winding, the output signal at the end of the winding is obtained by using the grounding resistor R According to the above data, the frequency sweep impedance value of the transformer can be obtained as:

[0065]

[0066] in, To detect the current, ω is the angular frequency of the injected signal; R is the resistance of the transformer; X is the reactance of the transformer.

[0067] Thus, the frequency sweep impedance value can be obtained as:

[0068]

[0069] Since the nameplate value of the transformer is generally represented by impedance voltage, the frequency sweep i...

Embodiment 3

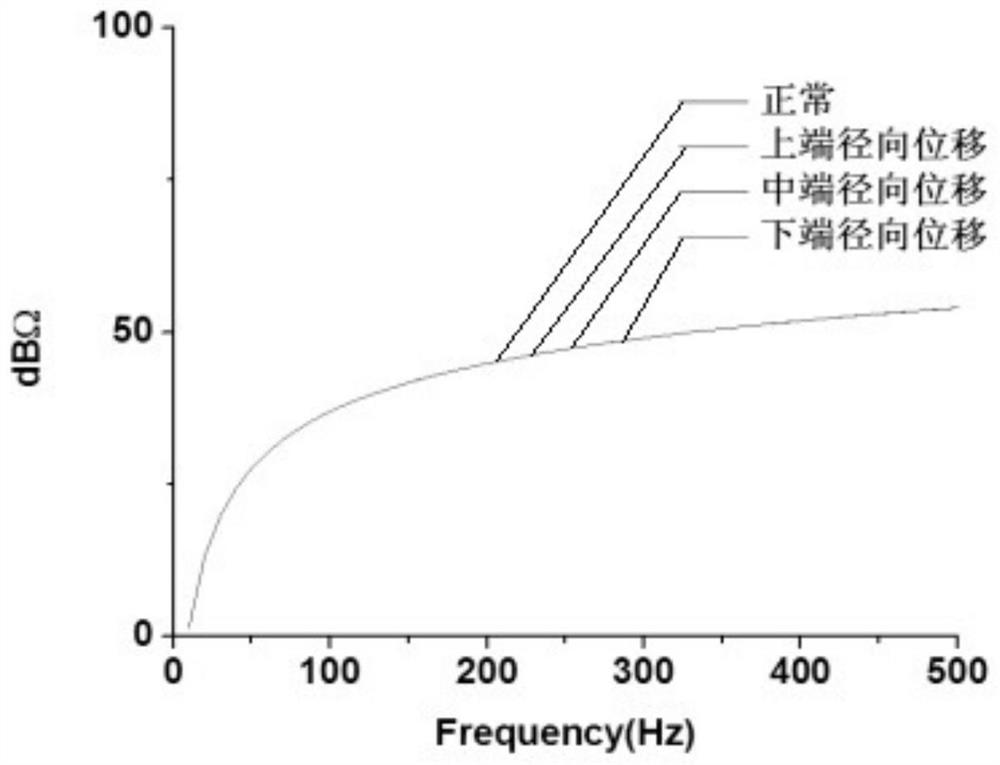

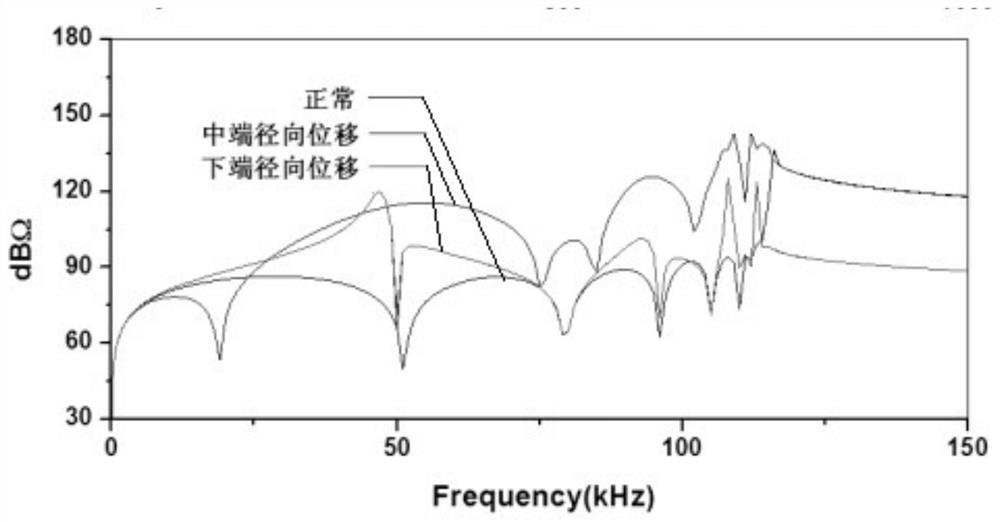

[0092] In this embodiment, when studying the radial displacement fault experiment of the winding, capacitors of 5.8pF, 18.3pF, 35.8pF and 220pF were selected (each grade of capacitance represents different degrees of winding deformation, wherein, 5.8pF: very slight deformation; 18.3pF: slight deformation; 35.8pF: moderate deformation; 220pF: large deformation), connected to the upper, middle and lower ends of the two-phase high-voltage windings of transformers A and B through wires (simulating faults at the upper, middle and lower terminals They are respectively placed in the two-phase 8 cake room, 24 cake room and 39 cake room). Experiments are carried out to obtain the frequency sweep impedance curves of each end and the experimental verification is carried out.

[0093] Such as Figure 4 as shown, Figure 4 It is the frequency sweep impedance curve under the radial displacement fault at the upper end. When the radial displacement of the transformer occurs at the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com