Welding method of superconducting film material

A welding method and superconducting thin film technology, applied in the direction of connecting contact materials, connections, electrical components, etc., can solve the problems of performance degradation of superconducting strips, damage to YBCO layers, etc., to improve performance, improve bending performance and mechanical strength , The effect of reducing the current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0033] An embodiment of a welding method of a superconducting thin film material of the present invention specifically includes the following steps:

[0034] S10, the surface of the superconducting bare strip is cleaned to remove impurities and oil stains on the surface of the superconducting bare strip, so as to facilitate the adhesion of the coating, enhance the weldability of the solder at the joint and the strip body 11, and also improve the mechanical properties of the welded joint Intensity, cleaning solutions such as alcohol or acetone can be selected for use during cleaning in this embodiment;

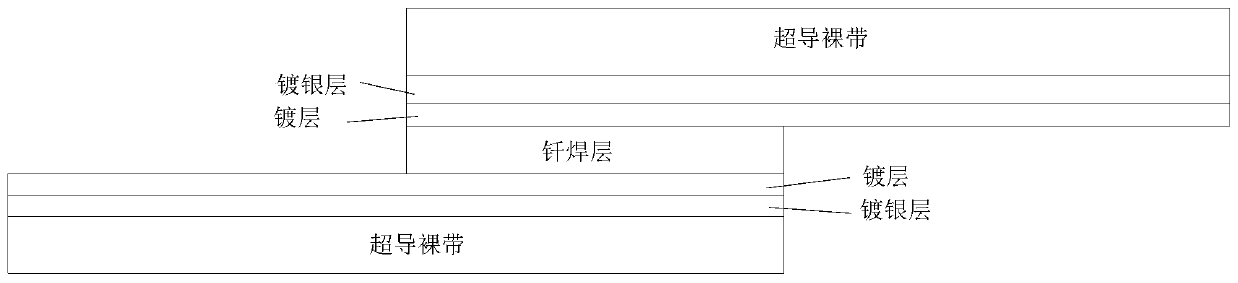

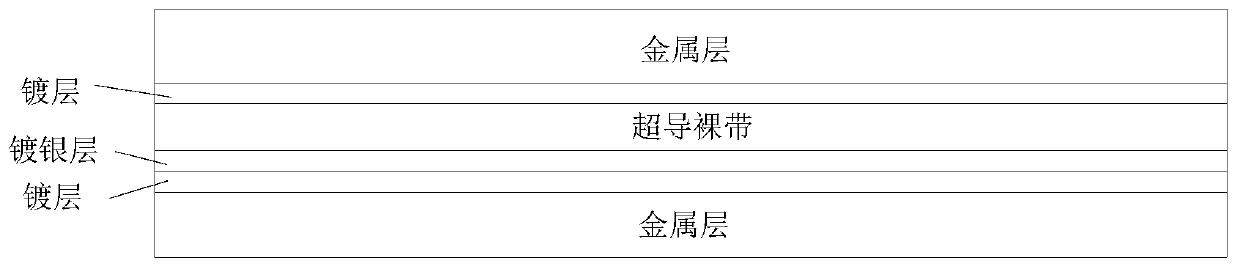

[0035] S11. The silver-plated layer of the bare superconducting strip covers t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com