Bulk acoustic wave resonator, filter and electronic device

A bulk acoustic wave resonator and resonator technology, applied to electrical components, impedance networks, etc., can solve the problems of reduced Q value and large energy loss of resonators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0052]A bulk acoustic wave resonator according to the present invention will be described below with reference to the drawings. It should be pointed out that, in the embodiments of the present invention, although the thin film bulk acoustic resonator is used as an example for illustration, these descriptions can be applied to other types of bulk acoustic wave resonators.

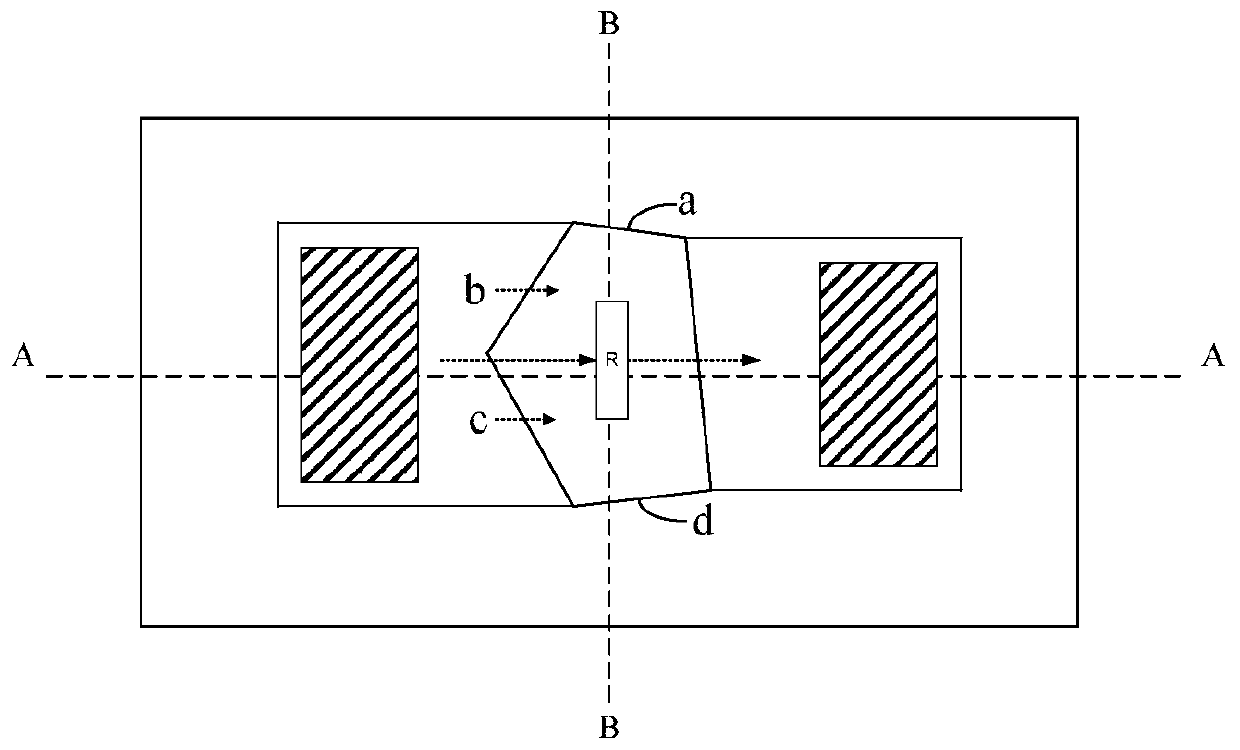

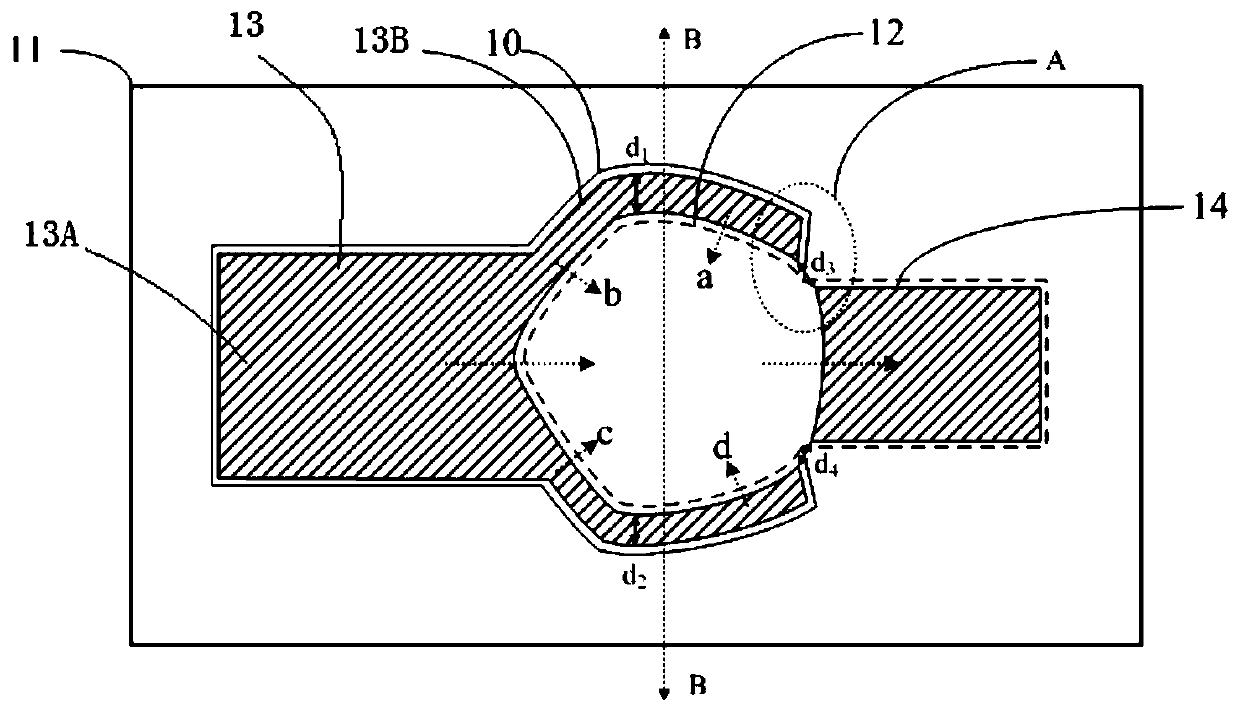

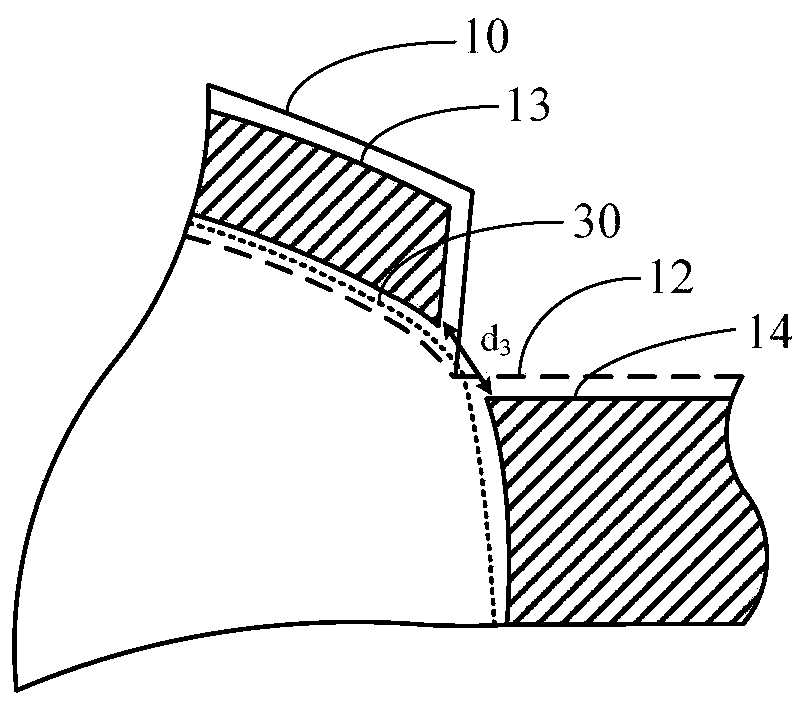

[0053] figure 2 is a schematic top view of a bulk acoustic wave resonator according to an exemplary embodiment of the present invention.

[0054] figure 2 In the shown e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap