Vapor chamber-type heat dissipation device

A technology of heat dissipation device and vapor chamber, which is applied in cooling/ventilation/heating transformation, modification using liquid cooling, electrical components, etc. It can solve problems such as poor operation of electronic equipment, and achieve enhanced convective heat transfer and circulation speed. , the effect of increasing the area of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

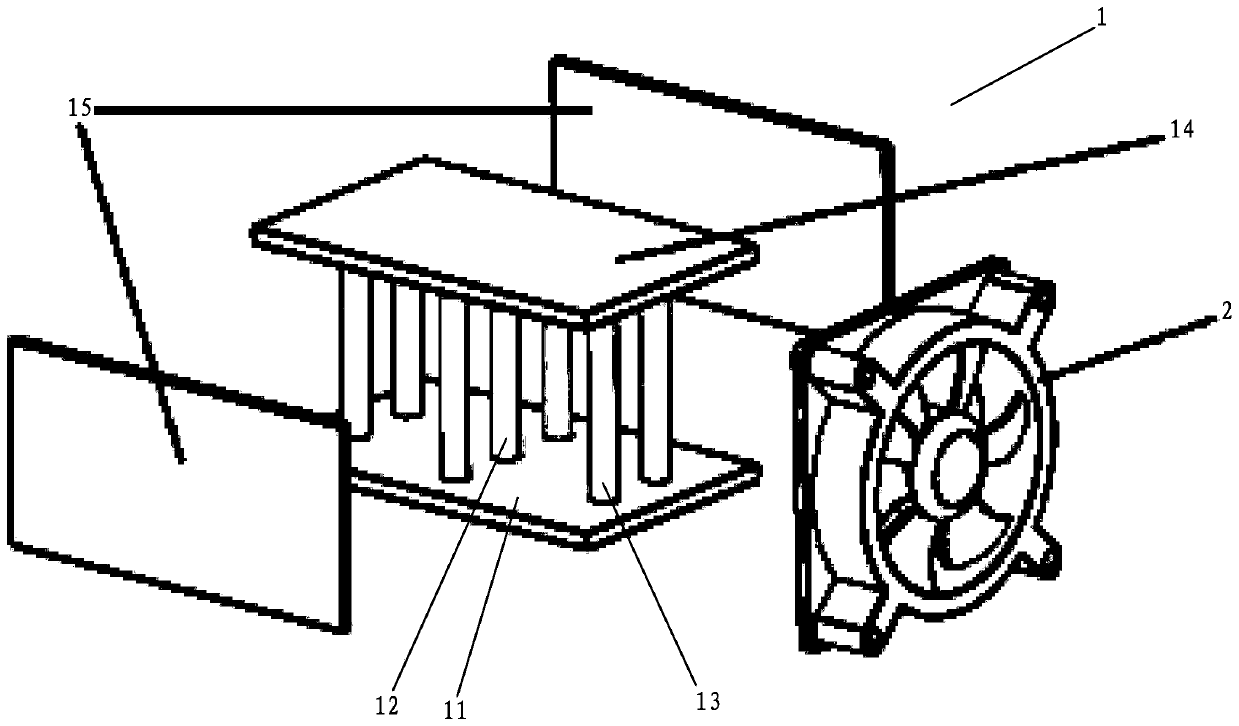

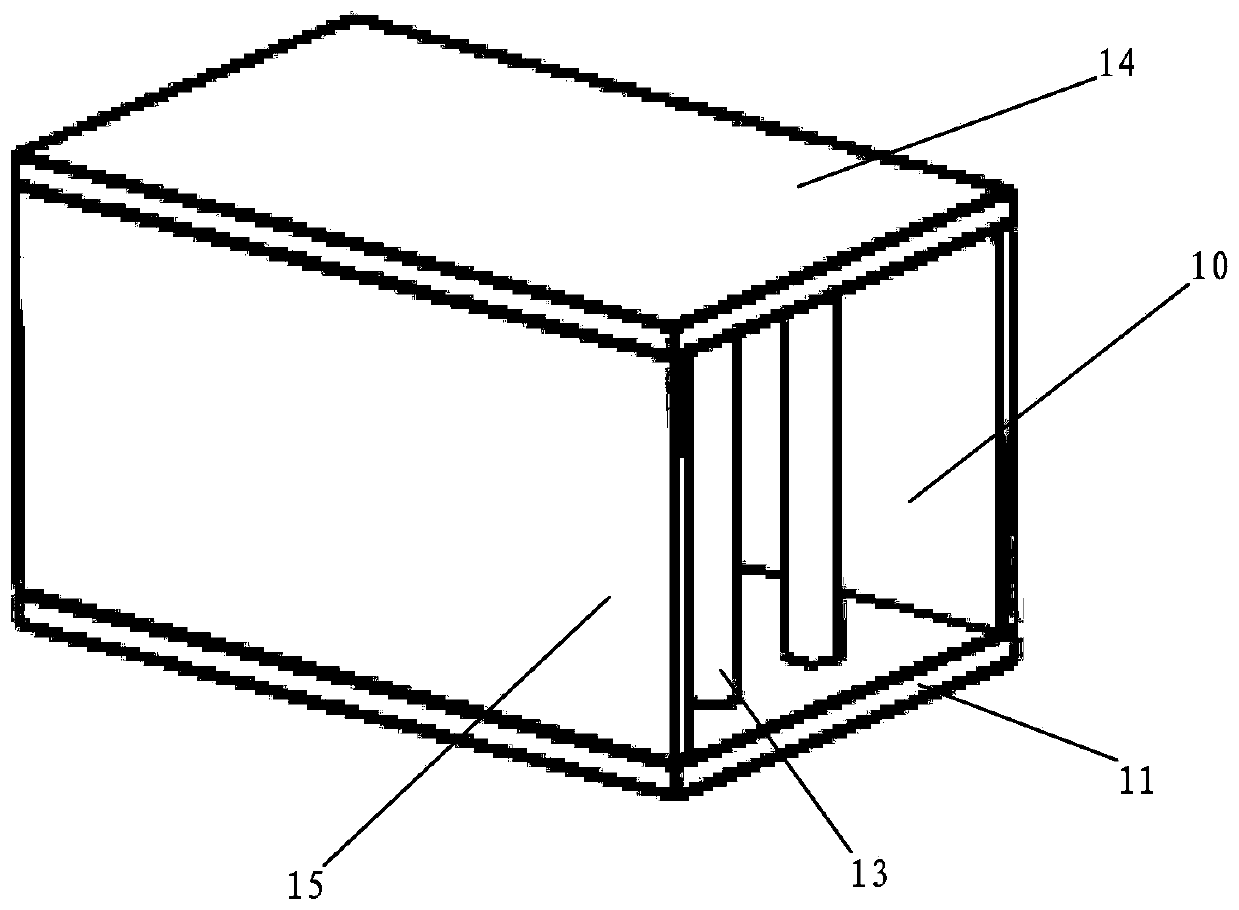

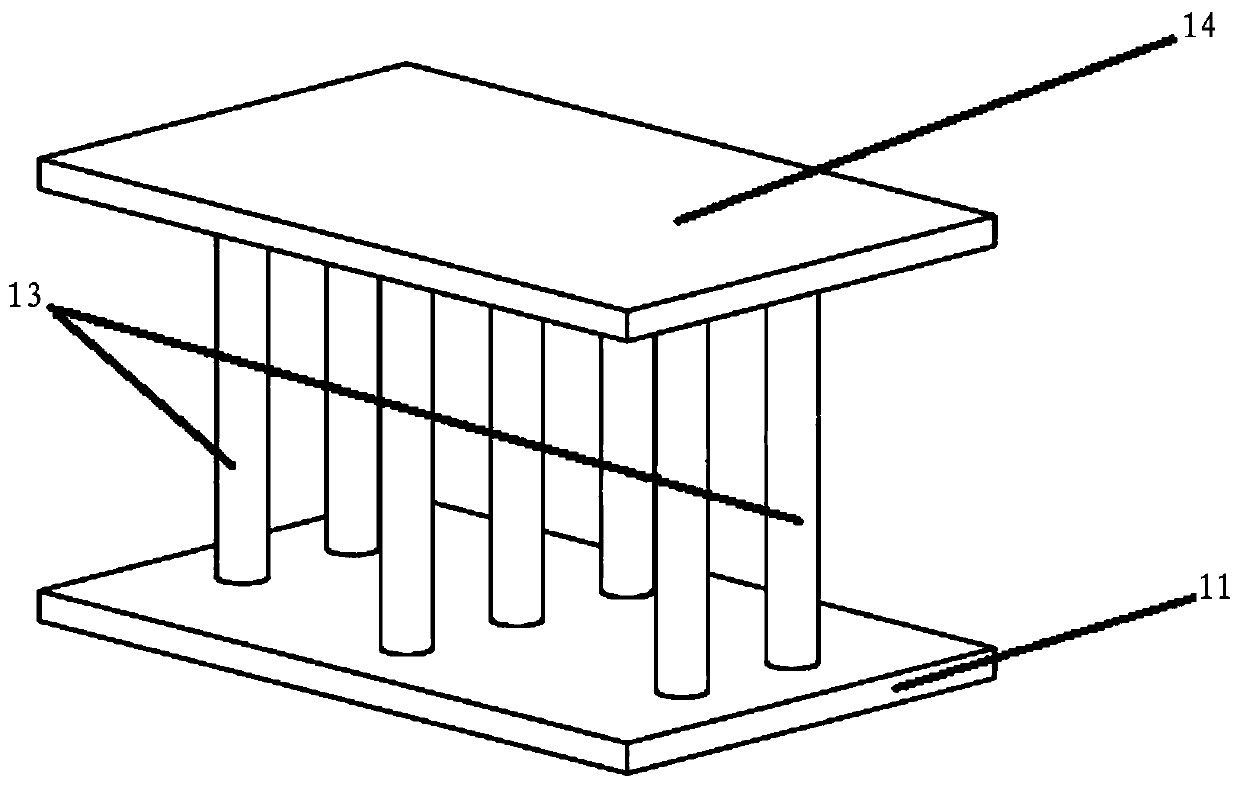

[0023] refer to Figure 1 to Figure 3 ,as well as Figure 5 , this embodiment relates to a vapor chamber heat dissipation device, including a heat conductor 1 and a fan 2, the heat conductor 1 is provided with an air duct 10, and the fan 2 is arranged on one end of the air duct 10; the heat conductor 1 includes an evaporation plate 11. Steam pipe 12, return pipe 13, condensing plate 14 and side plate 15. The evaporating plate 11 is in contact with the heat source to absorb the heat of the heat source. The evaporating plate 11 and the condensing plate 14 are hollow structures. The steam pipe 12 and the Both ends of the return pipe 13 are respectively connected and communicated with the evaporating plate 11 and the condensing plate 14 to form a sealed space; the side plates 15 are set to two and are respectively arranged on two opposite sides of the evaporating plate 11 and the condensing plate 14. On the side; the steam pipe 12 is arranged in the middle of the evaporating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com