Decontamination device used for cultivation

A high-pressure tank and air flotation technology, applied in application, fish farming, water pollutants, etc., can solve the problems of low removal efficiency of fine particles and proteins, adsorption capacity of large particles and proteins, and full utilization of ozone residues. Achieve the effect of improving ozone utilization efficiency and sterilization efficiency, easy application and low renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

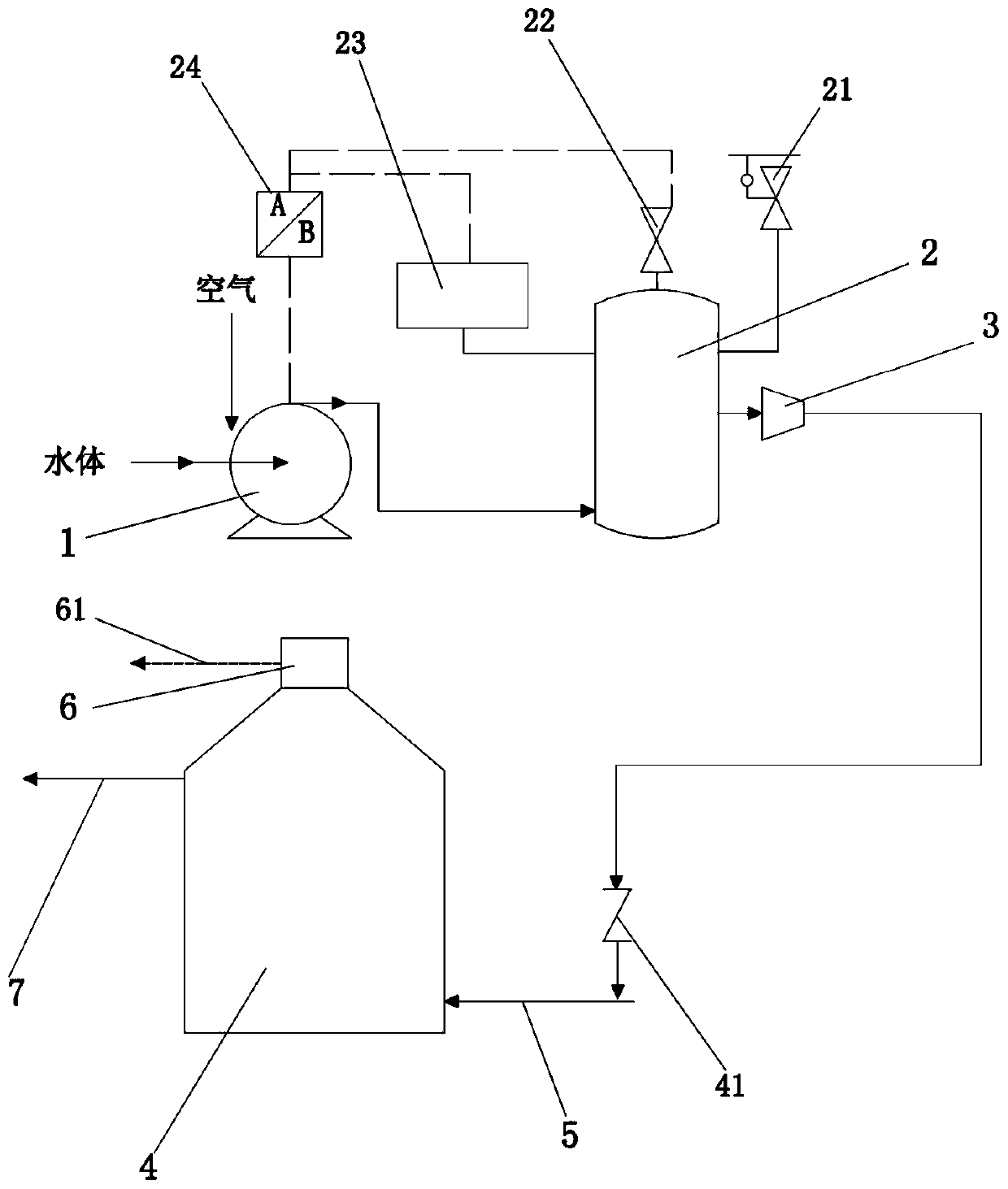

[0016] A kind of aquaculture decontamination device, such as figure 1 As shown, it includes a booster pump 1, a high-pressure tank body 2, and an air flotation bucket 4. The booster pump 1 is provided with a clean water suction port and an air suction port, and the outlet of the booster pump 1 is connected to the bottom inlet of the high-pressure tank body 2. Pass; the outlet of the high-pressure tank 2 is connected with a pressure release device 3, and the outlet end of the pressure release device 3 communicates with the water inlet pipeline 5 of the air float bucket 4 through a connecting pipeline; the air float bucket 4 The top is connected with a bubble collector 6; the bubble collector 6 is provided with a sewage pipe 61, and the upper part of the air flotation bucket 4 is provided with a drain pipe 7.

[0017] In this embodiment, a safety relief valve 21 is connected to the high-pressure tank body 2 .

[0018] In this embodiment, the high pressure tank 2 is connected wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com