Pipeline-type combined automatic sewage filtering device and method thereof

An automatic filtration and combined technology, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of on-site installation and layout restrictions of filters, failure to meet oil field production and operation, and affect sewage treatment, etc., to save labor time, The effect of reducing pollution and load intensity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

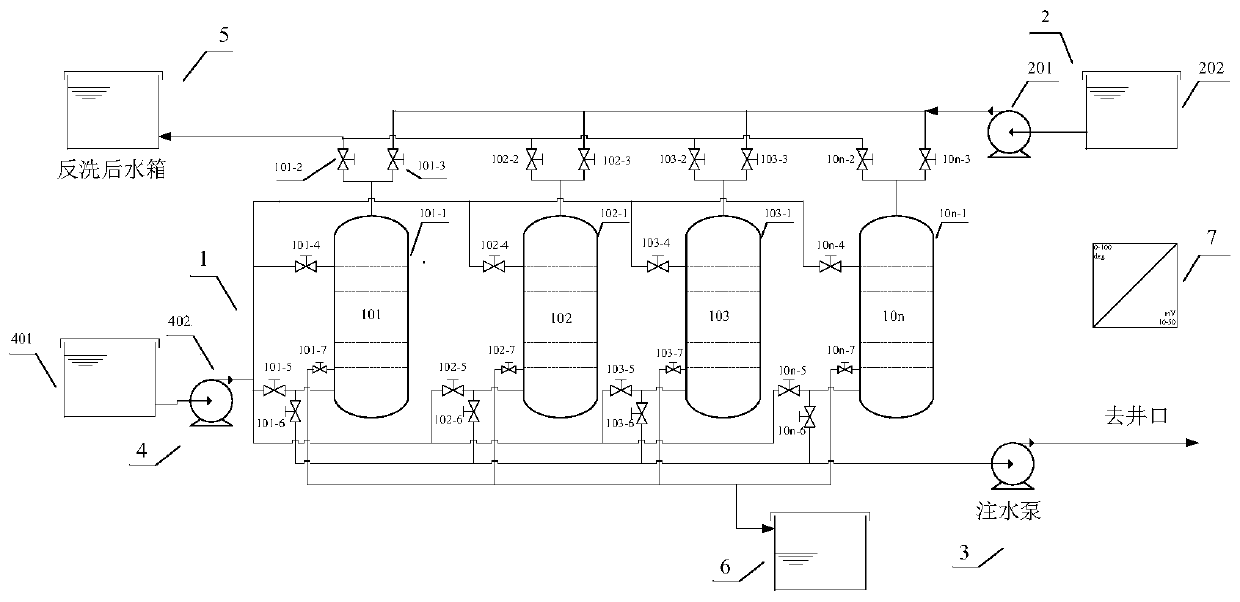

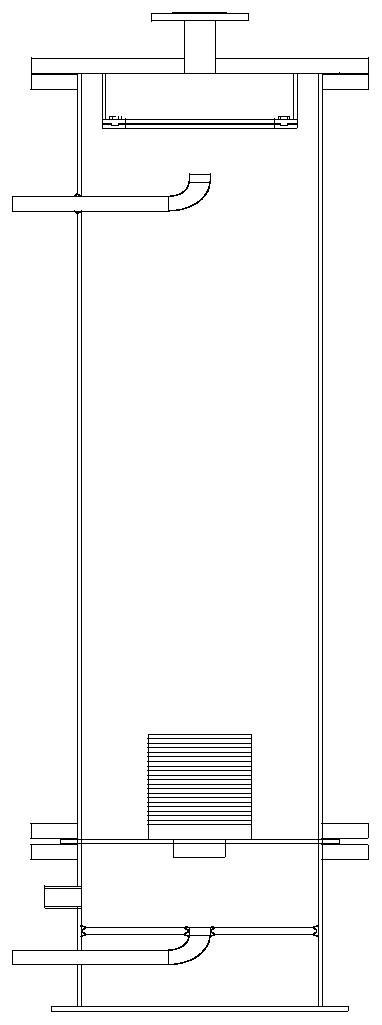

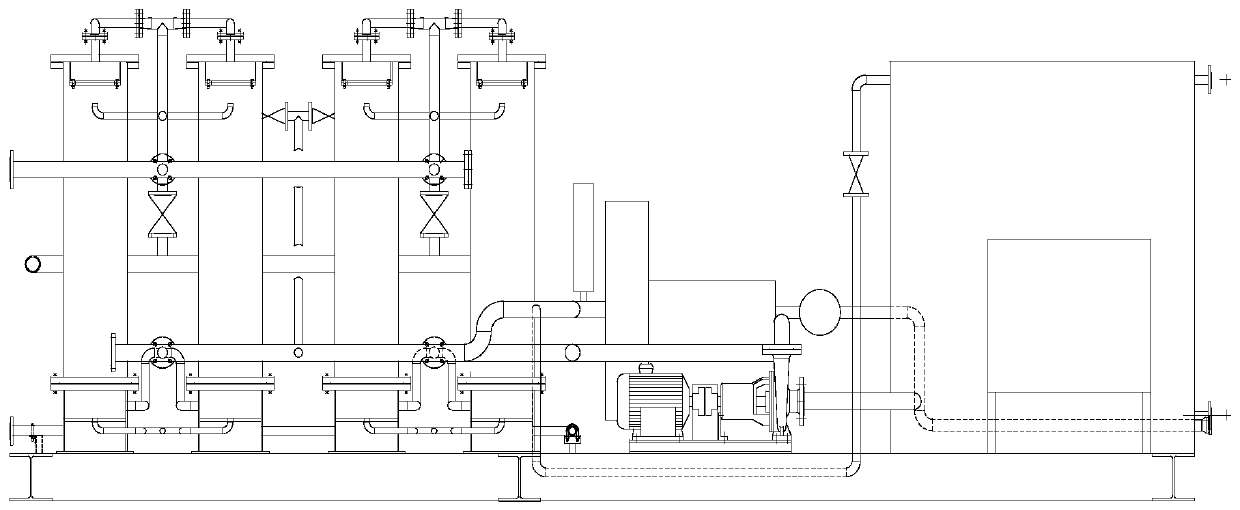

[0039] Such as figure 1 and figure 2 As shown, a pipeline-type combined sewage automatic filter device is characterized in that the device includes a filter unit 1, a filter water inlet unit 2, a filter water outlet unit 3, a backwash water inlet unit 4, and a backwash water outlet unit 5 , blowdown unit 6 and control unit 7; described filter water inlet unit 2, filter water outlet unit 3, backwash water inlet unit 4, backwash water outlet unit 5 and blowdown unit 6 are connected with filter unit 1 respectively, controller 7 Control the filter unit 1 , the filter water inlet unit 2 , the filter water outlet unit 3 , the backwash water inlet unit 4 , the backwash water outlet unit 5 and the sewage discharge unit 6 .

[0040] Preferably, the filter unit 1 is composed of a first filter unit 101 , a second filter unit 102 , a third filter unit 103 , .

[0041] The first filter unit 101 is composed of a first tubular filter 101-1, a first backwash water outlet electric valve 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com