Automatic control method for acyl chloride synthesis reaction

A synthesis reaction and acid chloride technology, applied in the field of automatic control that can realize fully automatic reaction, can solve the problems of inaccurate control, long reaction time, stable gas flow, etc., and achieve the effect of ensuring equipment safety, shortening reaction time and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

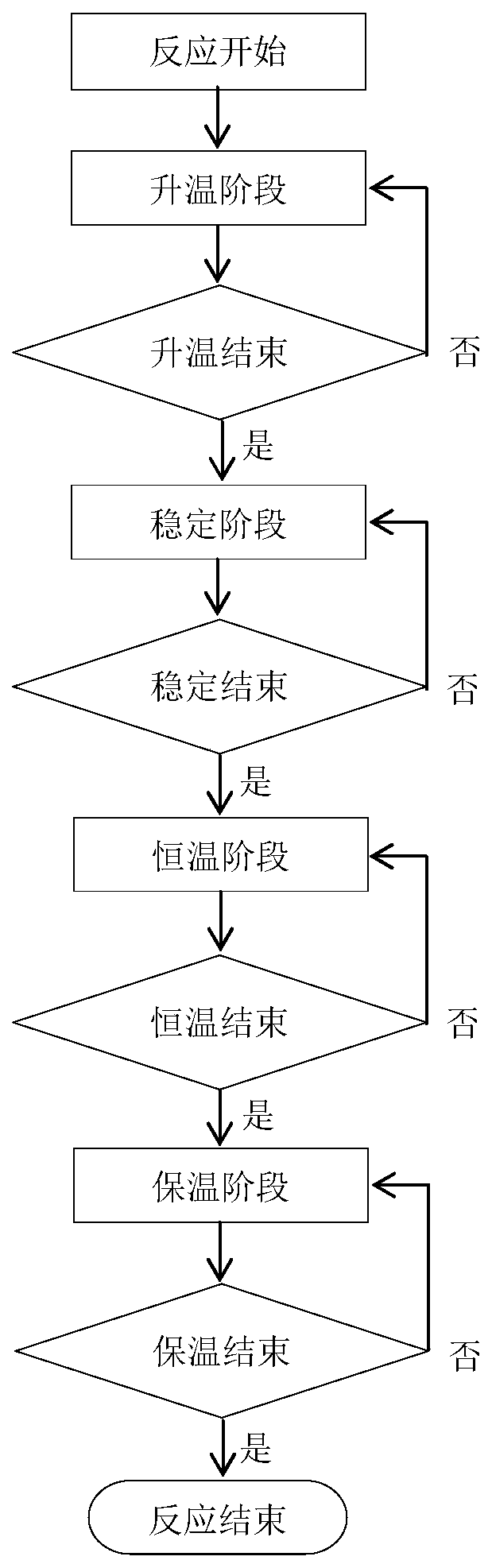

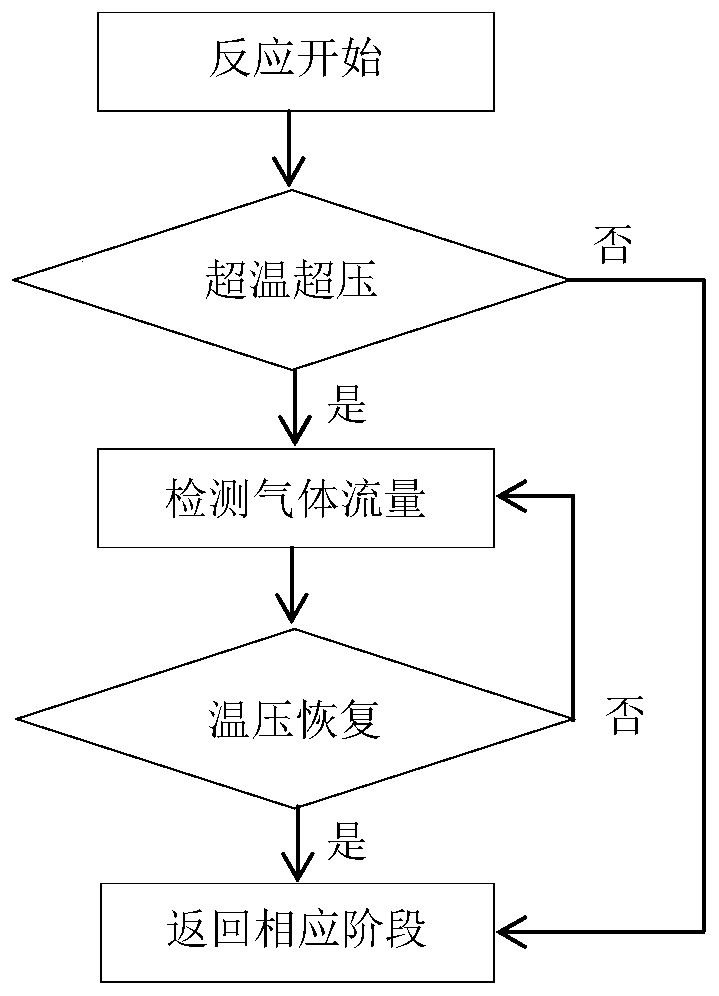

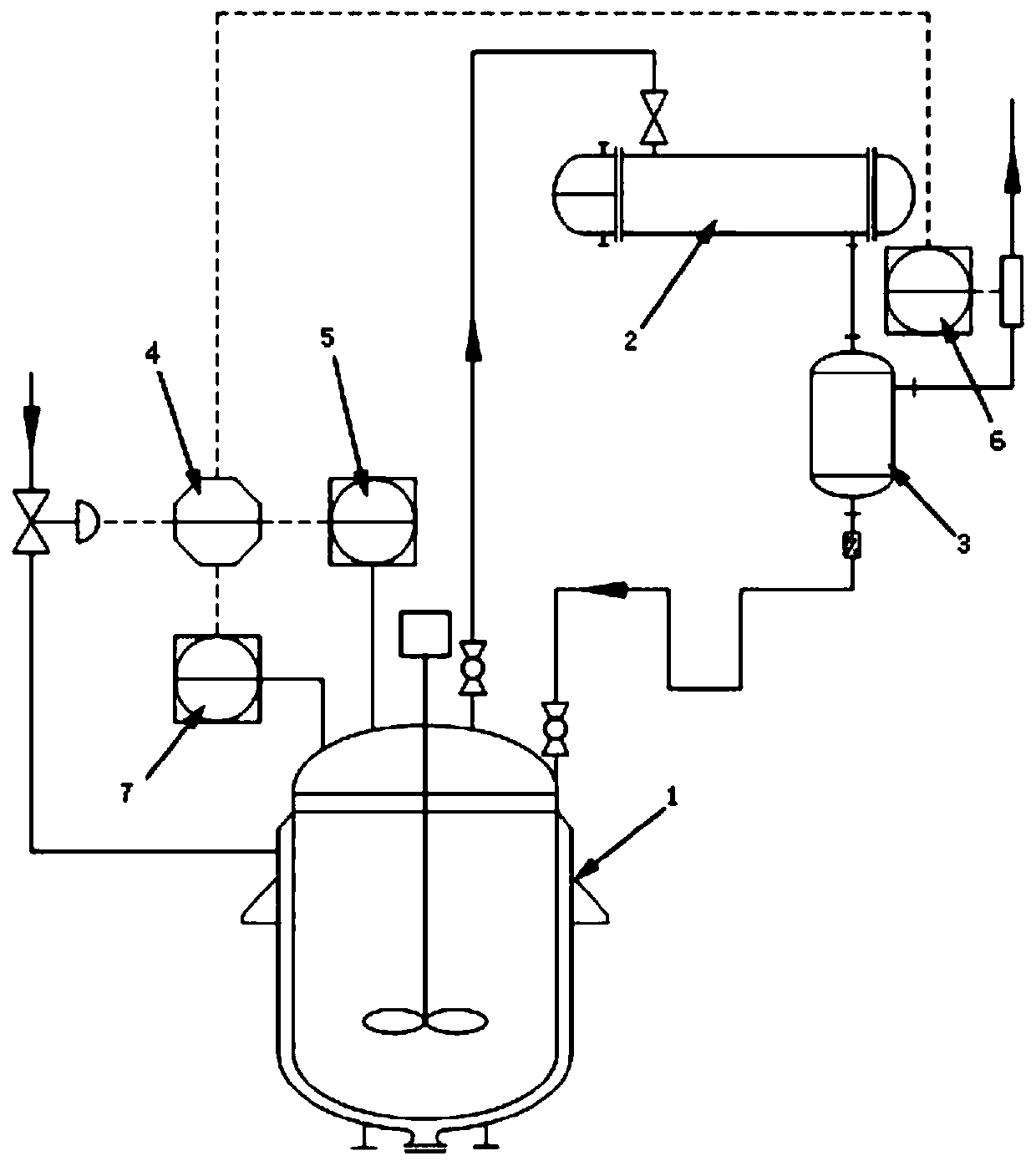

[0027] Such as Figure 1 to Figure 3 As shown, the automatic control method of the acid chloride synthesis reaction, the DCS control system terminal 4 is connected to the temperature detector 7, the flow detector 6 and the pressure detector 5, the jacket of the reactor 1 is provided with a steam regulating valve, and the steam regulating valve is connected to the DCS Control system terminal 4, reactor 1 is connected with heat exchanger 2 via gas-liquid separator 3, gas-liquid separator 3 is connected with flow detector 6, pressure detector 5 and temperature detector 7 are both connected with reactor 1, temperature The detector 7 is used to detect the temperature in the reactor 1. The reaction gas in the reactor 1 is separated by the gas-liquid separator 3 and the gas flow is detected by the flow detector 6, and the pressure detector 5 is carried out in the reactor 1. Pressure detection, the steam regulating valve is used to adjust and control the parameters of the flow, pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com