Grinding Monitoring Method Based on Thermal-Mechanical Coupling

A heat-mechanical coupling and grinding technology, which is applied in the direction of automatic grinding control devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of large fluctuations in grinding temperature and grinding force, falling off, and affecting grinding Surface quality and other issues to achieve the effect of ensuring the grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

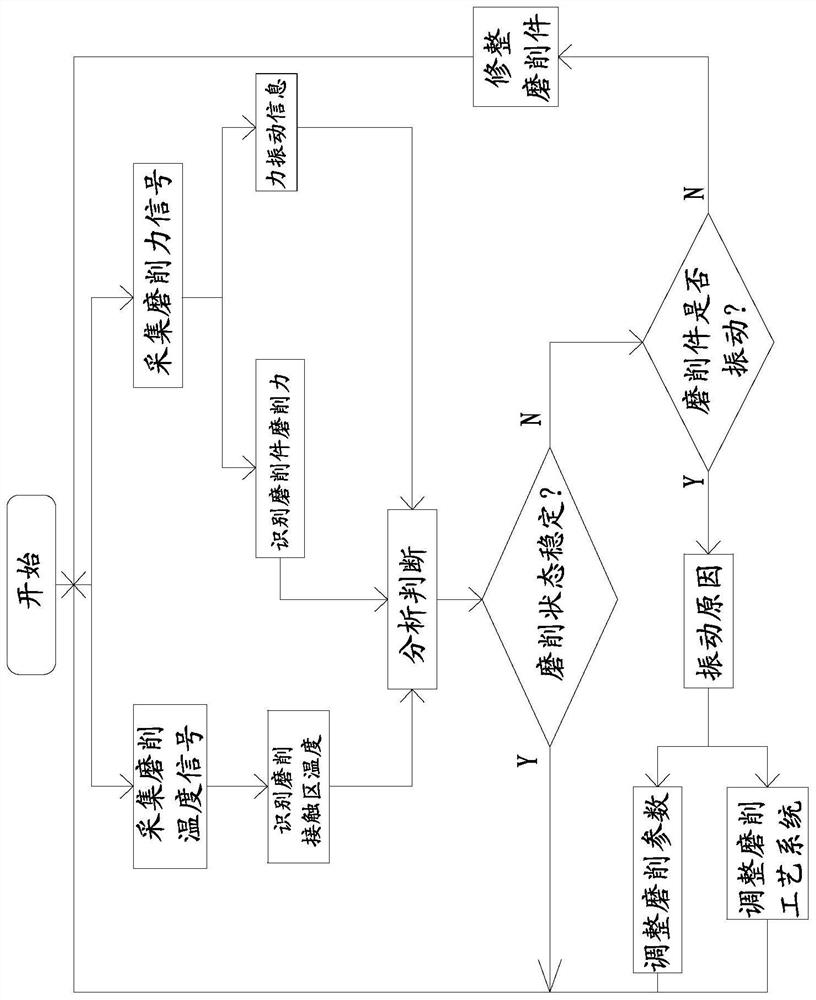

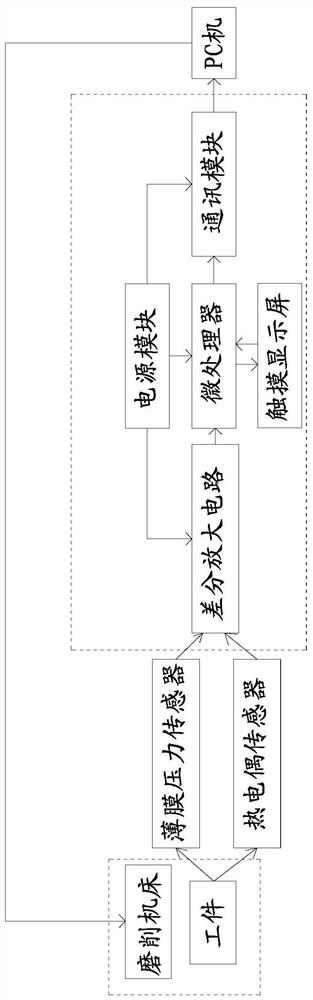

[0038] A grinding monitoring method based on thermal-mechanical coupling, such as Figure 1-4 shown, including the following steps:

[0039] A1: Setting the threshold: determine the grinding force threshold for grinding cracks, the temperature threshold for burns on the surface of the grinding part, and the fluctuation threshold for vibration of the grinding part:

[0040] A2: Collecting information of grinding parts: during the grinding process of grinding parts, the grinding temperature signals are collected at intervals per unit time, and the grinding signals collected per unit time form a temperature signal set, and then every Collect the generated grinding force signals at intervals, and the collected grinding force signals per unit time form a force signal set;

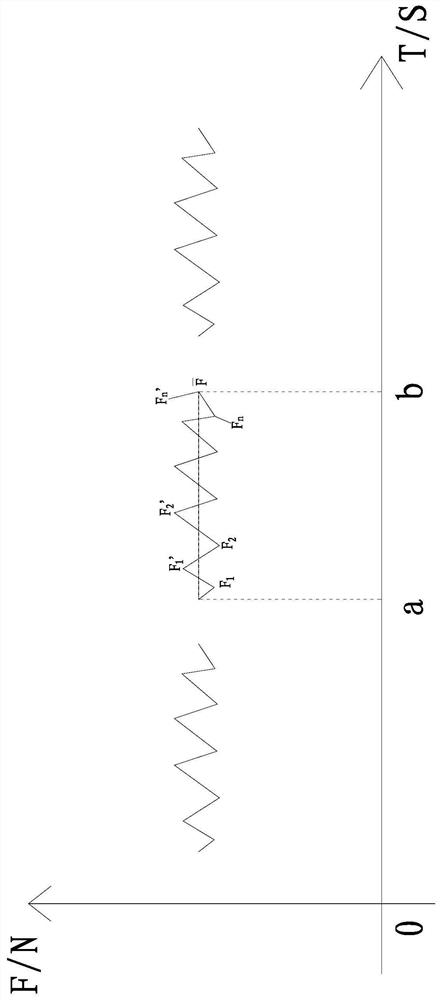

[0041] A3: Obtain the grinding piece dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com