Variable-interval suction head assembly

A technology of components and suction cups, which is applied in the field of automatic pick-and-place devices, can solve the problems of unfavorable production control, easy leakage, and high production costs, so as to improve production efficiency and product yield, high stability and reliability, The effect of saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

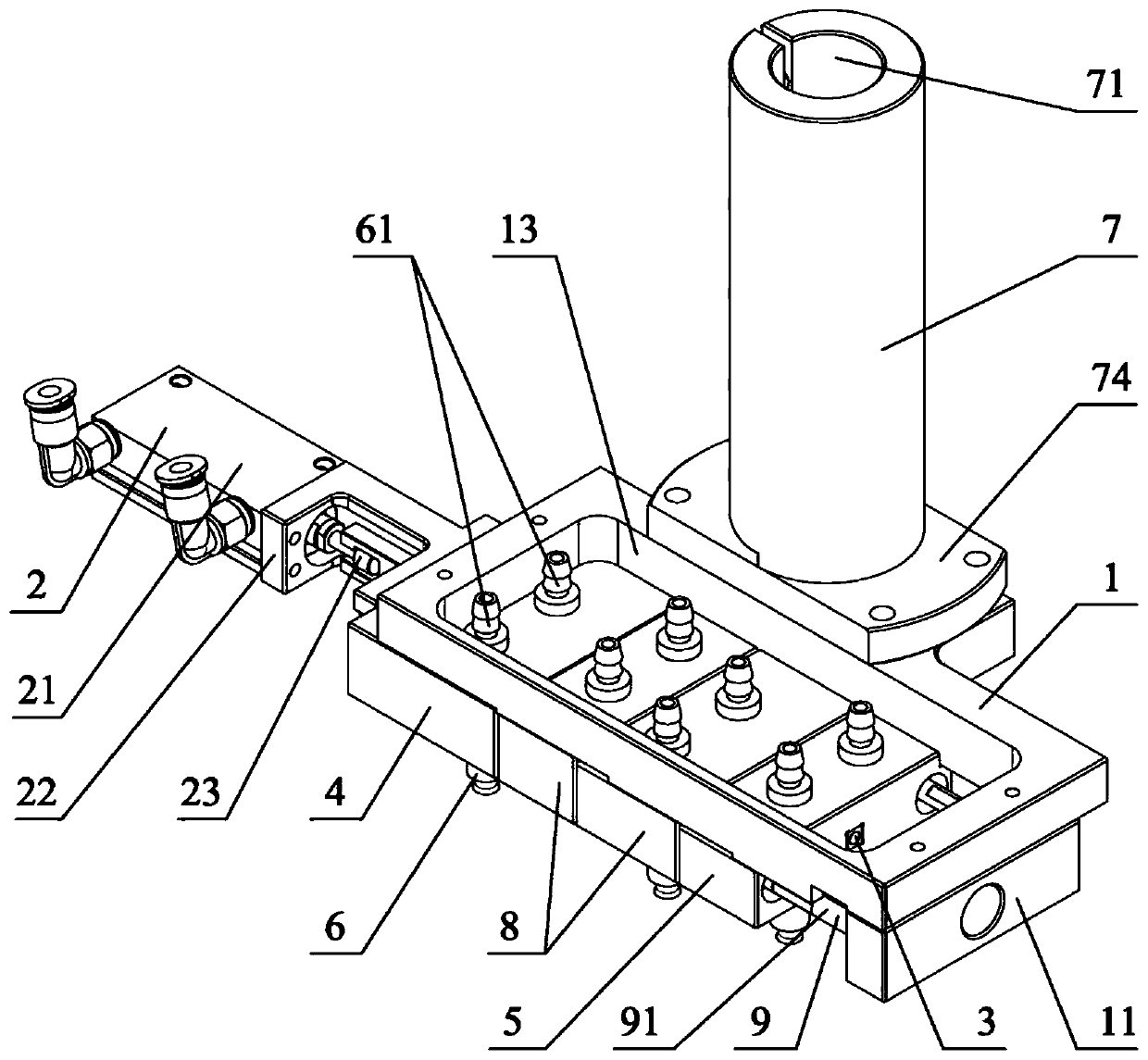

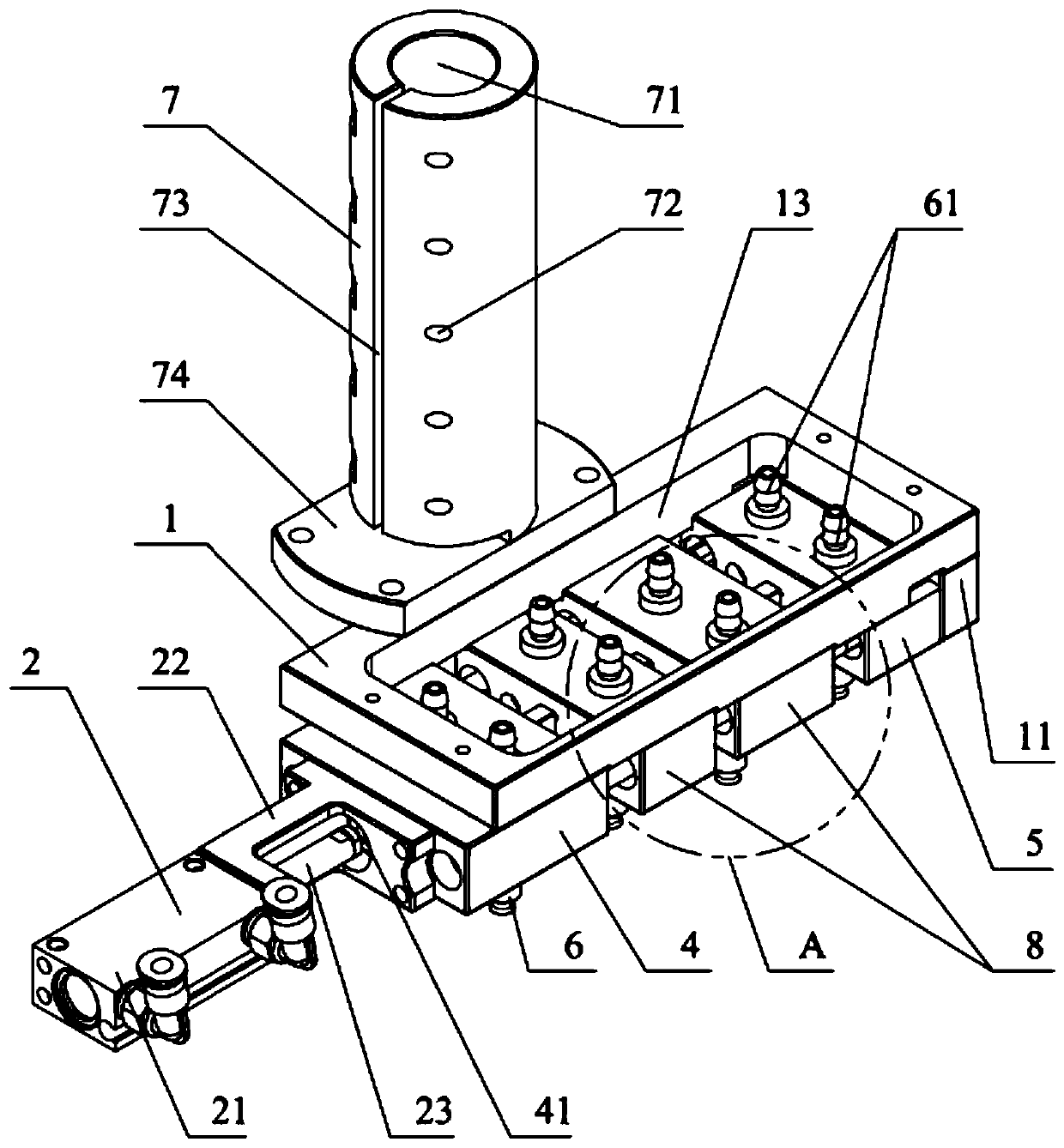

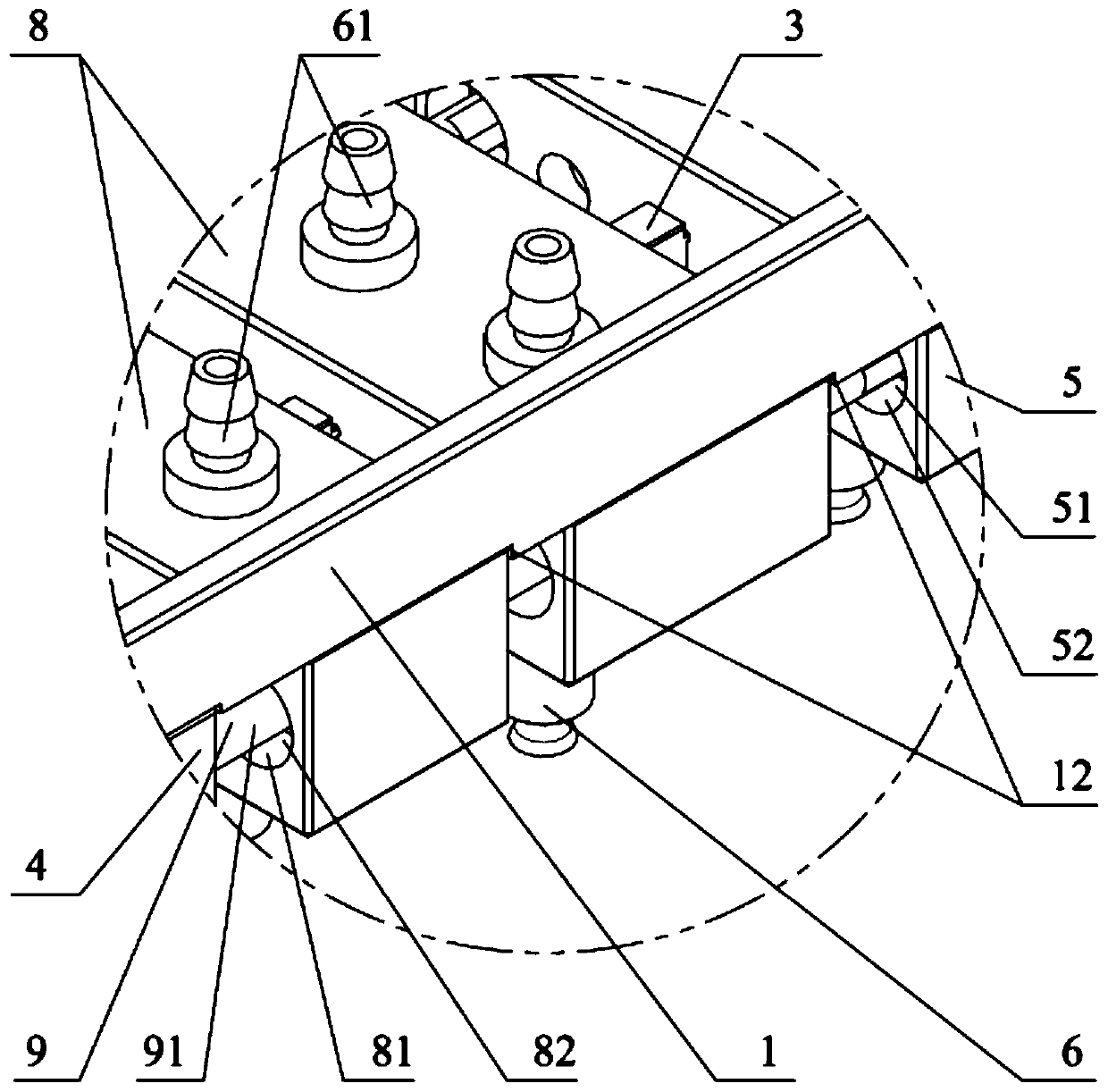

[0029] Such as Figure 1~4 As shown, a variable-pitch suction head assembly includes a fixed seat 1, on which a pushing mechanism 2, a push rod 3 driven by the pushing mechanism 2, and a fixed block 4 and a first sliding block arranged sequentially along the push rod 3 are arranged on the fixed seat 1. Block 5, the fixed block 4 is provided with the first through hole 41 for the push rod 3 to pass through, the fixed block 4 is located between the push mechanism 2 and the first slider 5, the first slider 5 is fixedly connected with the push rod 3, The fixed seat 1 is also provided with a limit plate 11 that limits the sliding distance of the first slider 5, and a group of suction cups 6 are arranged on the fixed block 4 and the first slider 5, and the suction cups 6 are used to suck corresponding products. The quantity and arrangement of 6 are determined according to specific conditions, and one set of suction cups 6 includes one, two or more suction cups 6 . The manipulator a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com