Ejection seat HTY-6 type packaging box and manufacturing method

A HTY-6, ejection seat technology, applied in the direction of transportation and packaging, to prevent mechanical damage, containers, etc., can solve the problems of poor cushioning effect, inconvenient disassembly and hoisting of packaging boxes, and improve stability, Convenient hoisting process, transportation process, and simple and fast disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

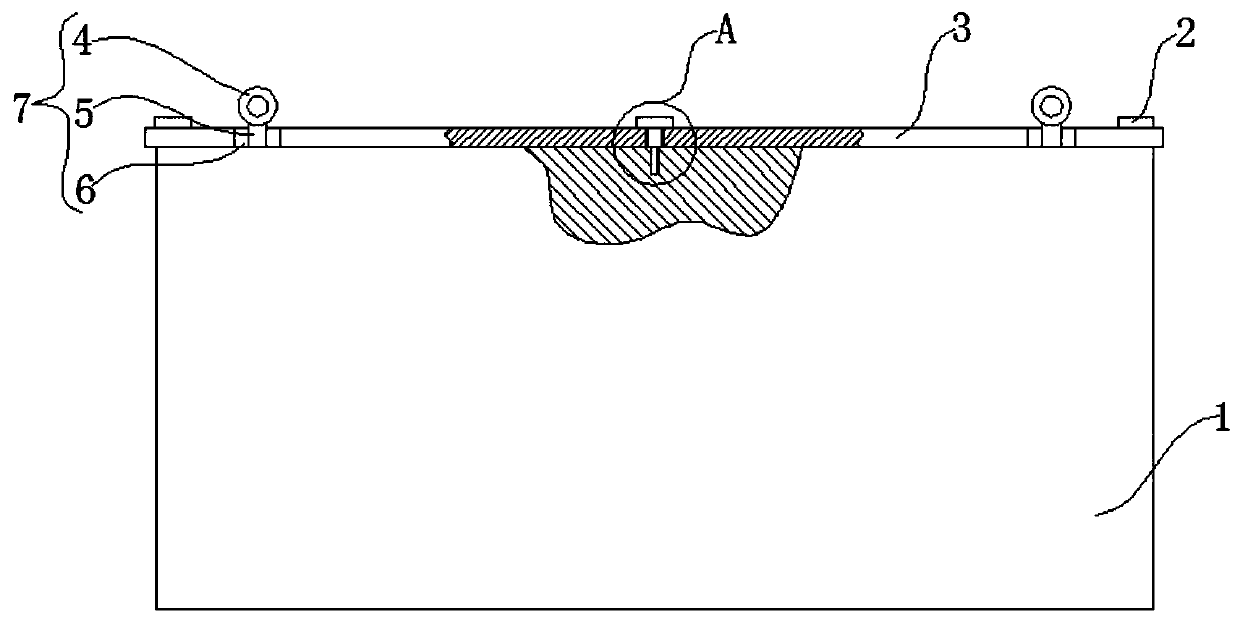

[0030] refer to Figure 1-5 , an ejection seat HTY-6 packaging box and a preparation method thereof, comprising a box body 1, the upper end of the box body 1 is evenly fixed with several fastening mechanisms 2, and the upper end of the box body 1 is fixedly connected by several fastening mechanisms 2 There is a cover 3, and the middle part of the lower surface of the cover 3 is bonded with a cushioning layer 23, and the cushioning layer 23 is a rubber pad. By using the cushioning layer 23 of the rubber pad, the cushioning and protection of the packaged seat can be effectively performed. role.

[0031] Four hoisting mechanisms 7 are arranged between the cover 3 and the upper end of the box body 1, and the four hoisting mechanisms 7 are respectively arranged at the four corners of the upper end of the box body 1, and a rubber base 14 is bonded to the middle part of the inner bottom of the box body 1, and the rubber base 14 is placed on the upper surface of the seat body 15, and...

Embodiment 2

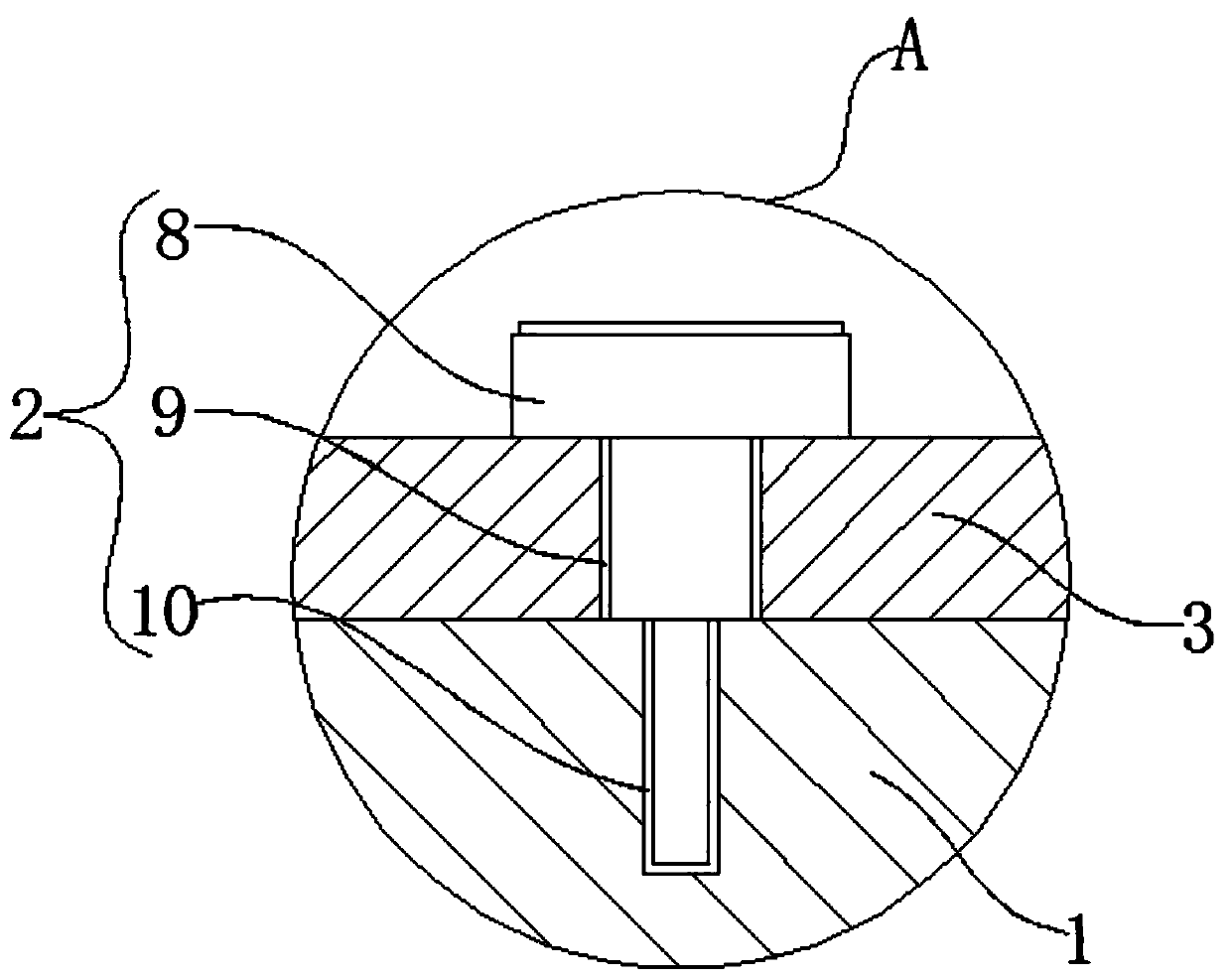

[0033] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the fastening mechanism 2 includes a manual fastening screw 8, a port 9 and a threaded hole 10, the port 9 is opened on the cover 3, and the threaded The hole 10 is set on the upper end of the box body 1, and the manual fastening screw 8 runs through the port 9 and the threaded hole 10 at the same time. Through this design, the cover 3 can be quickly and conveniently fastened and installed on the box body 1, and the disassembly process It is also simple and fast, and the whole process of disassembly and assembly can be completed by only one person, and it only needs to be done manually without the help of other auxiliary tools.

Embodiment 3

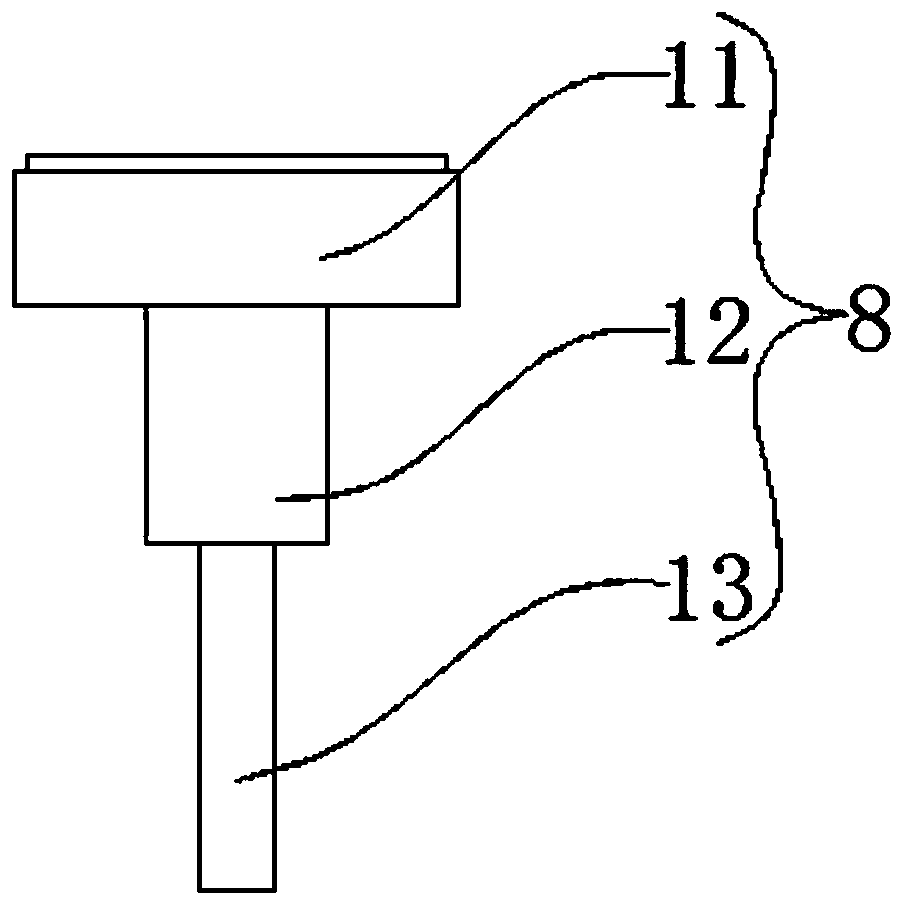

[0035] refer to Figure 2-3, as another preferred embodiment of the present invention, the difference from Embodiment 2 is that the manual fastening screw 8 includes a bolt head 11, and the middle part of one end of the bolt head 11 is fixedly connected with a positioning post 12, and the positioning post 12 is rotatably inserted into the Located in the port 9, the middle part of one end of the positioning column 12 is fixedly connected with a threaded rod 13, and the threaded rod 13 is threaded in the threaded hole 10. Through this design, during the assembly process of the cover 3 and the box body 1, the positioning column 12 is always rotated in the port 9, so that the accuracy of installation and positioning between the cover 3 and the box body 1 can be improved, and the stability of its assembled structure can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com