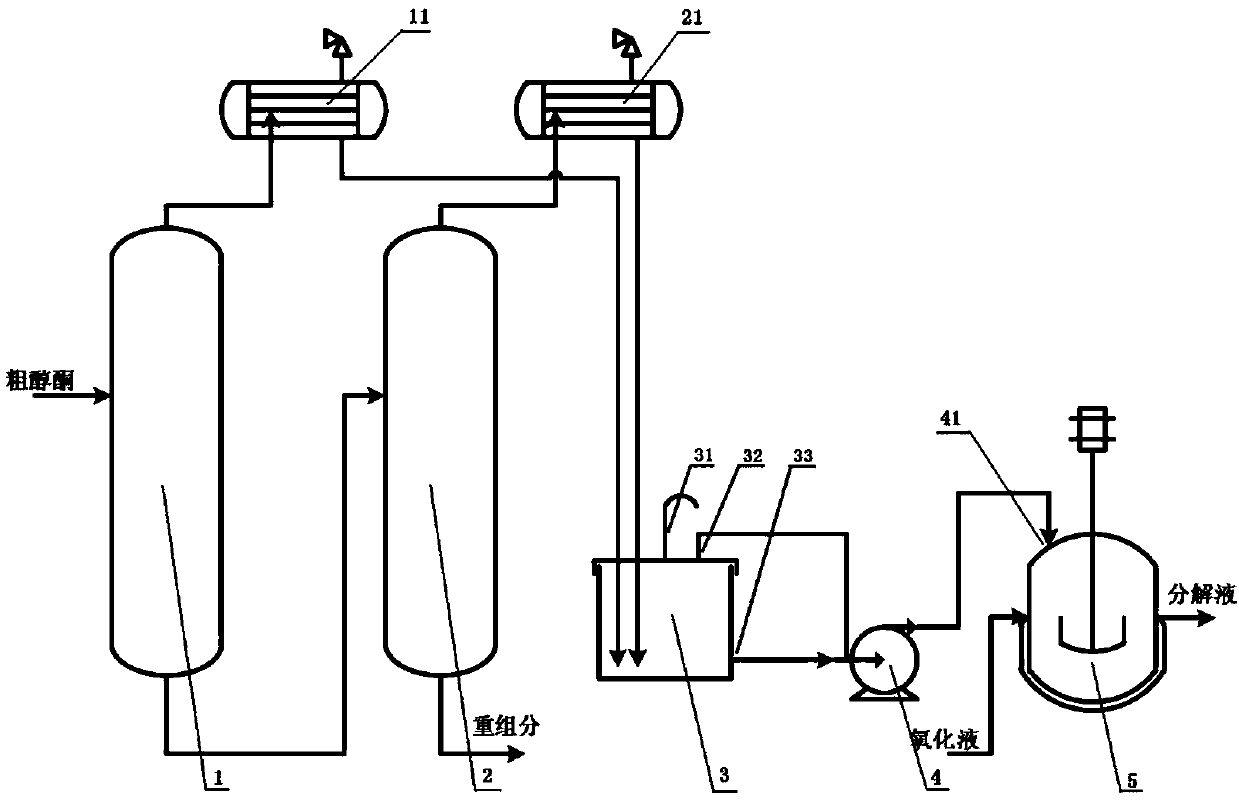

Method for reducing COD content in discharged wastewater of cyclohexanone device

A cyclohexanone, a technology outside the device, applied in the field of cyclohexanone production, can solve the problems of incomplete separation of condensate, large amount of waste water discharged, and high COD content, so as to reduce the discharge of gas phase, save consumption, and reduce organic matter. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A cyclohexanone plant with an annual output of 80,000 tons, the ventilation volume is about 13200Nm 3 / h, the vacuum condensate of the cyclohexanone tower / cyclohexanol tower is about 2t / h, and the organic matter content is 5.67%. The vacuum condensate of the cyclohexanone tower / cyclohexanol tower is treated by the technical scheme of the present invention, and the COD content in the waste water discharged from the stripping process is 2159 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com