Water-based two-component epoxy paint and preparation method thereof

A two-component epoxy paint technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of insufficient wetting of water-based coatings, unsatisfactory effects, and high requirements for substrate surface treatment, so as to improve the paint quality. Film compactness and adhesion, and the effect of improving protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

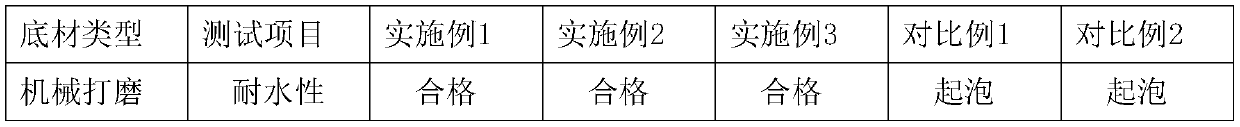

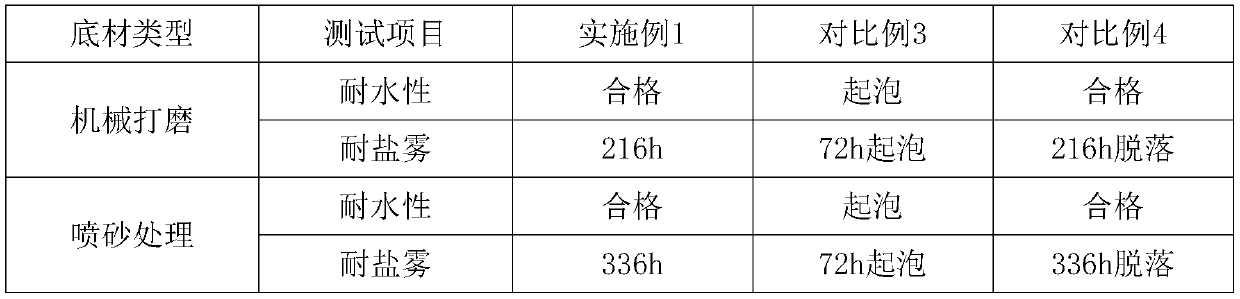

Embodiment 1

[0063] The present embodiment provides a kind of waterborne two-component epoxy paint with excellent anticorrosion effect, and its preparation method is as follows:

[0064] To prepare water-based resin-free anti-corrosion color paste, put pure water, dispersant (LUCRAMUL DA 130), pigment wetting agent (Surfynol AD01), defoamer (BYK011) into the container in sequence, and add anti-corrosion pigments (aluminum zinc phosphate, Aluminum tripolyphosphate, iron phosphorus powder, water-based aluminum powder) coloring pigments (titanium white, carbon black) fillers (sericite powder, precipitated barium sulfate) are dispersed at high speed, and after grinding, the color paste is obtained; the above ratios are water 35%, dispersant 1%, pigment wetting agent 0.5%, defoamer 0.5%, anticorrosion pigment 48%, coloring pigment 10%, filler 5%.

[0065] Prepare water-based two-component epoxy primer A component, epoxy emulsion ( PZ 3961-1) into the container, add substrate wetting agent (TEGO...

Embodiment 2

[0070] The present embodiment provides a kind of waterborne two-component epoxy paint with excellent anticorrosion effect, and its preparation method is as follows:

[0071] To prepare water-based resin-free anti-corrosion color paste, put pure water, dispersant (NUOSPERSE 2000), dipropylene glycol butyl ether, propylene glycol propyl ether, defoamer (BYK011) into the container in sequence, and add anti-corrosion pigment strontium calcium phosphate (HALOX_SZP- 391TDS), ion-exchanged silica antirust pigment (SHIELDEX C303), ferrophosphorus powder, coloring pigment (titanium white, iron oxide black), filler (sericite powder, precipitated barium sulfate) are dispersed at high speed, and after grinding, the Obtain the color paste; the above-mentioned ratios are respectively 30% of water, 2% of dipropylene glycol butyl ether, 3% of propylene glycol propyl ether, 1% of dispersant, 0.5% of defoamer, 48% of anticorrosion pigment, 10% of colored pigment, and 5% of filler.

[0072] To p...

Embodiment 3

[0077] The present embodiment provides a kind of waterborne two-component epoxy paint with excellent anticorrosion effect, and its preparation method is as follows:

[0078] To prepare water-based resin-free anti-corrosion color paste, put pure water, dispersant (TANEMUL DA345 C), pigment wetting agent (Surfynol AD01), defoamer (BYK011) into the container in sequence, and add anti-corrosion pigments (aluminum zinc phosphate, Aluminum tripolyphosphate, ferrophosphorus powder, water-based aluminum powder) coloring pigment (titanium white, iron oxide black) filler (sericite powder, precipitated barium sulfate) are dispersed at high speed, and after grinding, the color paste is obtained; the above ratios are respectively 35% water, 1% dispersant, 0.5% pigment wetting agent, 0.5% defoamer, 48% anti-corrosion pigment, 10% colored pigment, 5% filler.

[0079] Prepare water-based two-component epoxy primer A component, epoxy emulsion ( PZ 3961-1) into the container, add substrate we...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap