Shield machine hob alloy material

A technology of alloy materials and shield machines, which is applied in mining equipment, earthwork drilling, tunnels, etc., and can solve problems such as the short service life of hobs and the difficulty in meeting the technical specifications of high-quality hobs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

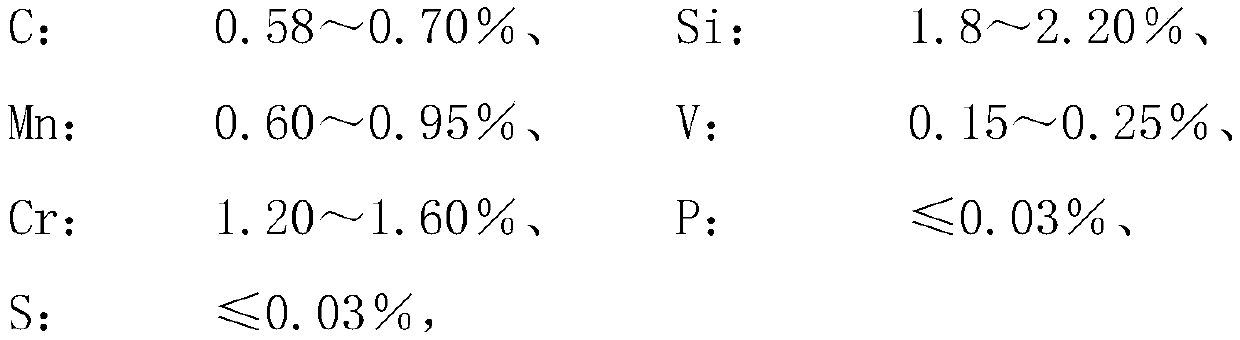

[0025] Example 1. A shield machine hob alloy material is composed of the following elements in terms of weight ratio:

[0026]

[0027] The rest is Fe and trace elements.

[0028] The above-mentioned alloy material is treated according to the following heat treatment method: keep the material at 880°C for 30 minutes, then put it in 50°C quenching oil to cool for 18s, then keep it in a salt bath at 270°C for 60 minutes, and finally cool it with water to room temperature.

[0029] The alloy obtained above has a hardness of 56HRC and an impact energy of 26J.

Embodiment 2

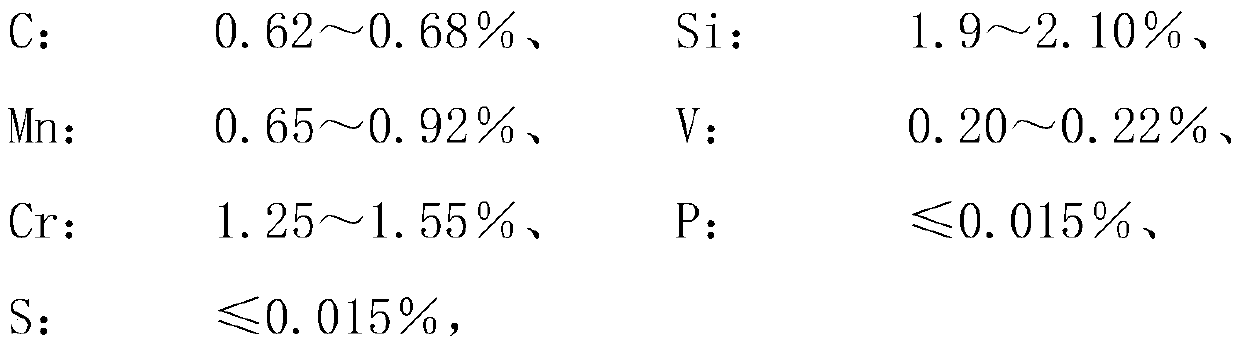

[0030] Example 2. A shield machine hob alloy material is composed of the following elements in terms of weight ratio:

[0031]

[0032] The rest is Fe and trace elements.

[0033] Heat treatment method is with embodiment 1.

[0034] The alloy obtained above has a hardness of 57HRC and an impact energy of 25J.

Embodiment 3

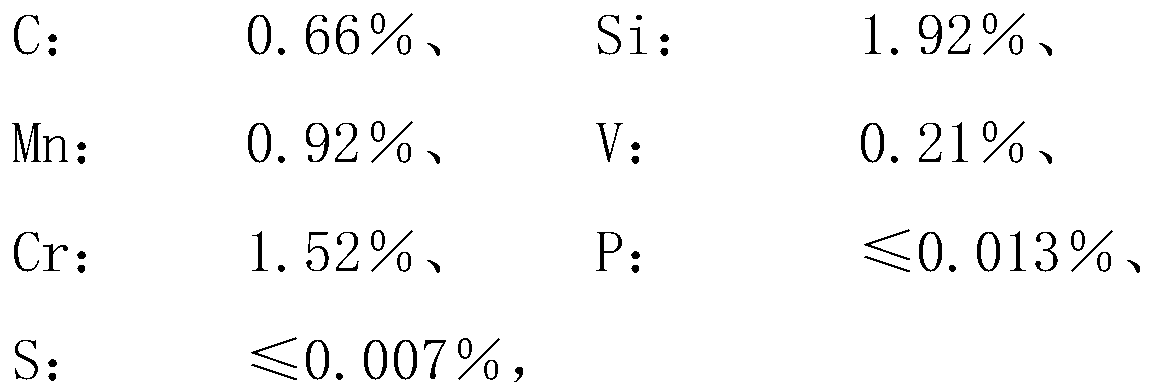

[0035] Example 3. A shield machine hob alloy material is composed of the following elements in terms of weight ratio:

[0036]

[0037] The rest is Fe and trace elements.

[0038] Preferably, the aforementioned shield machine hob alloy material is composed of the following elements by weight ratio:

[0039]

[0040] The rest is Fe and trace elements.

[0041] Heat treatment method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com