Metallized vanadium-titanium pellet and preparation method thereof

A technology of pelletizing and metallization, which is applied in the field of iron and steel metallurgy, can solve problems such as poor fluidity, high iron loss, and high melting temperature of slag, and achieve the effects of reducing fuel consumption, reducing ironmaking costs, and strengthening blast furnace smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

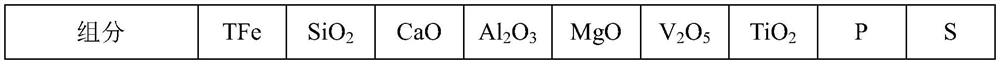

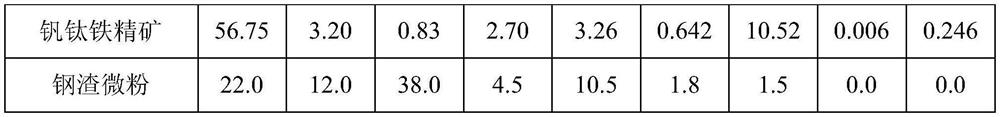

[0015] The invention provides a method for preparing metallized vanadium-titanium pellets. In the method, the raw material structure is "vanadium-titanium iron concentrate+dust dust+steel slag micropowder". Among them, the vanadium ilmenite concentrate is a high-titanium type vanadium ilmenite concentrate in the Panxi area, and the composition of the vanadium ilmenite concentrate contains not less than 56% TFe and less than 4% SiO by weight. 2 , 0.5~1% CaO, 2~3% Al 2 O 3 , 0.5~0.8% of V 2 O 5 , 9~11% TiO 2 , less than 0.01% of P, less than 0.5% of S, and FeO content of 20 to 30%. Dust removal ash is the dust removal dust produced in the coke production process, including coal charging dust removal dust, coke dry quenching dust dust removal and coke sieving dust removal dust, etc. The composition of dust removal dust contains not less than 75% C by weight percentage, and does not contain iron. Steel slag micropowder is the powder of vanadium-containing steel slag produced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com