Oil soluble corrosion inhibitor for oil pipe of gas well and preparation method thereof

An oil-soluble corrosion inhibitor and tubing technology, which is applied in the fields of petroleum and petrochemical, gas well tubing and equipment protection, can solve the problems affecting the stability and anti-corrosion effect of corrosion inhibitors, and achieve good planar spreadability, good compatibility, and no corrosion resistance. The effect of easy desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

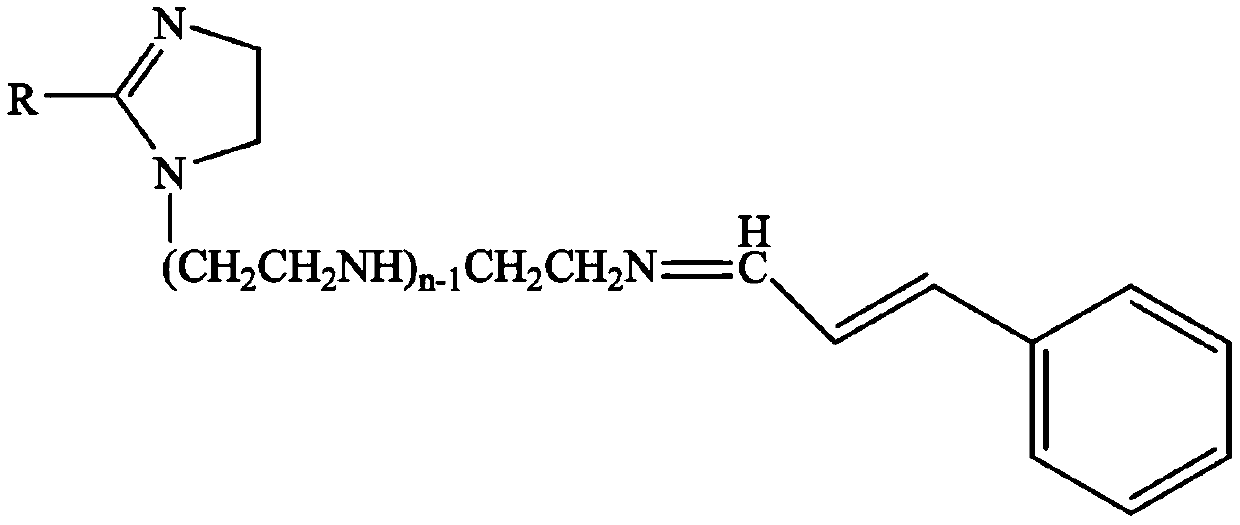

[0031] Embodiment 1 of the present invention provides an oil-soluble corrosion inhibitor for gas well tubing. According to the mass fraction, its raw material is composed of 25% of the main agent and 75% of the compound, wherein the main agent is imidazoline Schiff base, and the compound The compound is based on the total mass of the oil-soluble corrosion inhibitor for gas well tubing, and the compound is composed of 10% benzotriazole, 7% hydroxyethyl thiosuccinic acid, and 58% solvent naphtha 200#.

[0032] Specifically, the preparation method of an oil-soluble corrosion inhibitor for gas well tubing comprises the following steps:

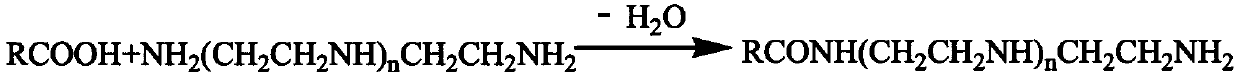

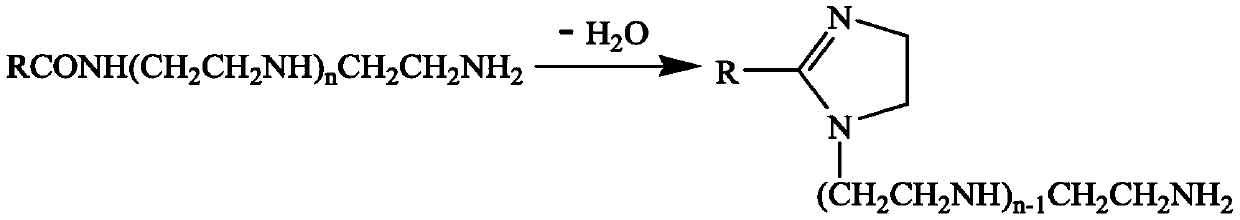

[0033] (1) Aspartic acid and diethylenetriamine are added into the reaction kettle according to the molar ratio of 1:1.2 for reaction, and water-carrying agent xylene is added at the same time, wherein the xylene water-carrying agent is oil for gas well tubing 10% of the total mass of the soluble corrosion inhibitor, heating and stirring to 150-16...

Embodiment 2

[0045] Embodiment 2 of the present invention provides an oil-soluble corrosion inhibitor for gas well tubing. According to the mass fraction, its raw material is composed of 20% of the main agent and 80% of the compound, wherein the main agent is imidazoline Schiff base, and the compound The compound is based on the total mass of the oil-soluble corrosion inhibitor for gas well tubing, and the compound is composed of 15% aromatic azole, 10% hydroxyethyl thiosuccinic acid and 55% solvent.

[0046] Wherein, the aromatic azole is selected from mercaptobenzothiazole, and the solvent is selected from solvent naphtha 100#.

[0047] Specifically, the preparation method of an oil-soluble corrosion inhibitor for gas well tubing comprises the following steps:

[0048] (1) Aspartic acid and triethylenetetramine are added to the reaction kettle according to the molar ratio of 1:1.5 to react, and xylene water-carrying agent is added at the same time, wherein the water-carrying agent xylene...

Embodiment 3

[0060] Embodiment 3 of the present invention provides an oil-soluble corrosion inhibitor for gas well tubing. According to the mass fraction, its raw materials are composed of 20% of the main agent and 80% of the compound, wherein the main agent is imidazoline Schiff base, and the compound The compound is based on the total mass of the oil-soluble corrosion inhibitor for gas well tubing, and the compound is composed of 10% aromatic azole, 5% hydroxyethyl thiosuccinic acid and 65% solvent.

[0061] Wherein, the aromatic azole is selected to be methyl benzotriazole, and the solvent is selected mineral spirits 100#.

[0062] Specifically, the preparation method of an oil-soluble corrosion inhibitor for gas well tubing comprises the following steps:

[0063] (1) Aspartic acid and tetraethylenepentamine are added to the reaction kettle according to the molar ratio of 1:1.5 to react, and xylene water-carrying agent is added at the same time, wherein the water-carrying agent xylene i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com