System and method for continuously preparing carbon nano tube fibers based on floating catalytic CVD method

A technology of carbon nanotube fiber and floating catalysis, applied in chemical instruments and methods, fiber chemical characteristics, inorganic chemistry, etc. Unstable carbon source and catalyst supply, etc., to achieve continuous production, uniform speed, precise and controllable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

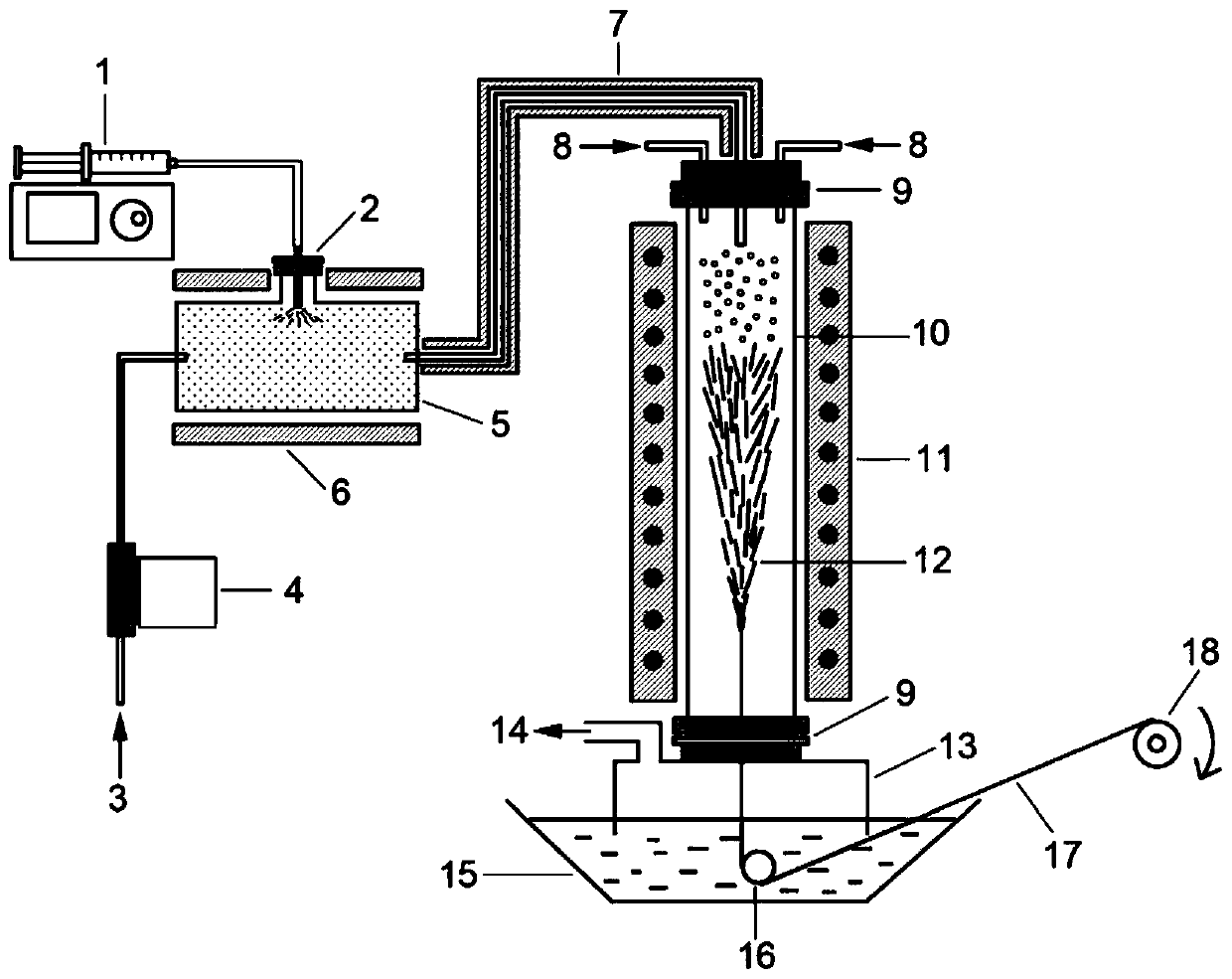

[0027] The system for continuously preparing carbon nanotube fibers based on the floating catalytic CVD method provided by the embodiment of the present invention uses a heating gasification system independent of the high-temperature growth zone to vaporize and gasify the liquid carbon source / catalyst and mix it with the carrier gas evenly, and then pass The temperature-controllable pipeline is transported into the high-temperature growth area, so as to realize the stable and continuous supply of carbon source and catalyst and the continuous preparation of carbon nanotube fibers with high uniformity.

[0028] An embodiment of the present invention provides a system for continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com