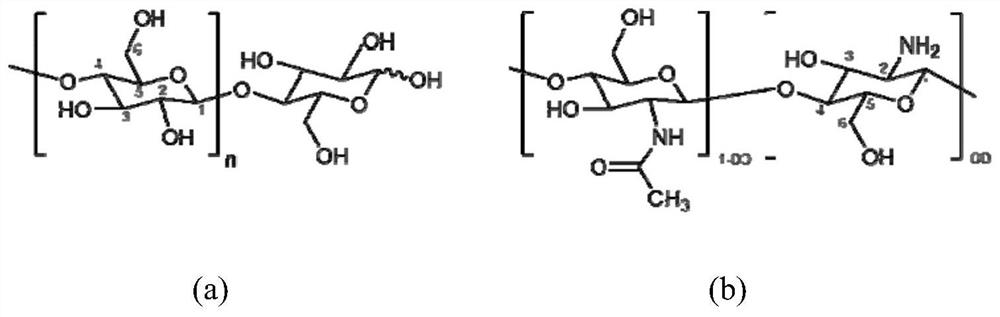

A paper-making filling method based on in-situ growth of gel-coated MOFs

An in-situ growth and gel technology, which is applied in the field of paper filling, can solve the problems of impact, little increase in the retention rate of retention aids and fillers, and poor results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

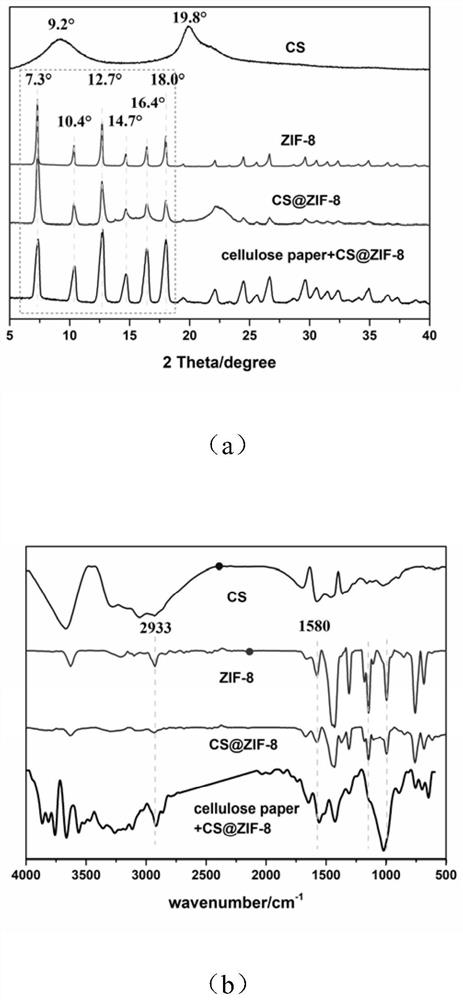

Image

Examples

Embodiment 1

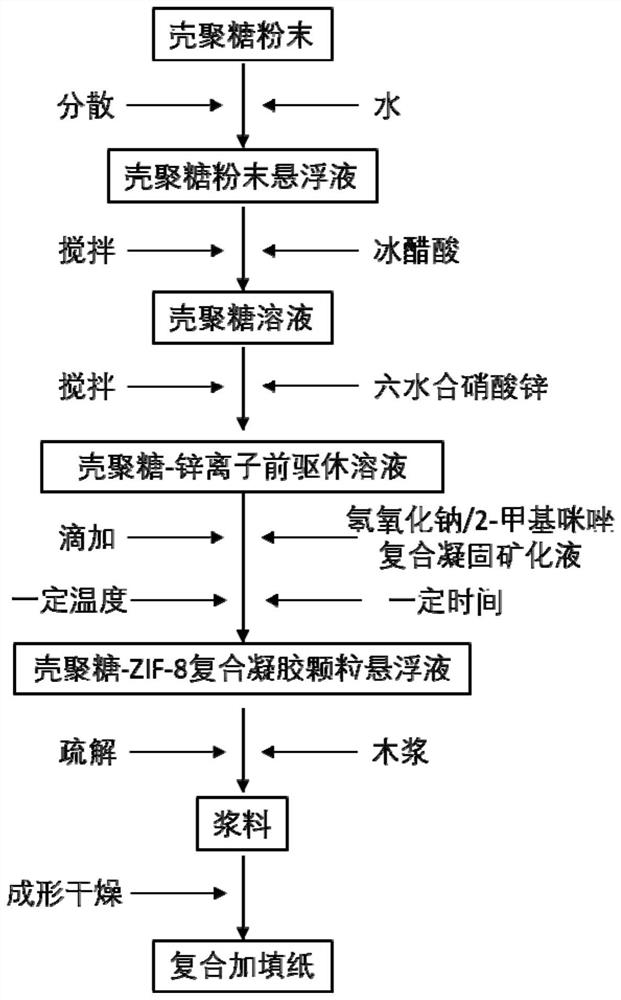

[0038] (1) Prepare chitosan-metal ion solution: take 0.1g chitosan powder, fully disperse in 99.9mL deionized water, obtain chitosan powder suspension; add 2mL glacial acetic acid, stir and dissolve to obtain chitosan solution; add 0.9g zinc nitrate hexahydrate again, stir and dissolve fully, obtain chitosan-zinc ion precursor solution;

[0039] (2) Prepare chitosan-metal ion-ligand gel: prepare (5.0%) sodium hydroxide and 2-methylimidazole (5%) composite coagulation bath, under 1000r / min stirring effect, to sodium hydroxide Add the chitosan-zinc ion precursor solution dropwise to the 2-methylimidazole composite coagulation bath until the chitosan completely forms a gel to obtain the chitosan-metal ion-ligand composite flocculent gel suspension;

[0040] (3) Preparation of chitosan-ZIF-8 composite gel particles: the chitosan-metal ion-ligand composite flocculent gel suspension obtained in the collection step (2) is transferred to a polytetrafluoroethylene reactor. At room tem...

Embodiment 2

[0043] (1) Prepare chitosan-metal ion solution: weigh 0.2g chitosan powder, fully disperse in 99.8mL deionized water to obtain chitosan powder suspension; add 2mL glacial acetic acid, stir and dissolve to obtain chitosan solution; add 1.2g zinc nitrate hexahydrate again, stir and dissolve fully, obtain chitosan-zinc ion precursor solution;

[0044] (2) Prepare chitosan-metal ion-ligand gel: prepare (8.0%) sodium hydroxide and 2-methylimidazole (5.0%) composite coagulation bath, under 1000r / min stirring effect, to sodium hydroxide Add the chitosan-zinc ion precursor solution dropwise to the 2-methylimidazole composite coagulation bath until the chitosan completely forms a gel to obtain the chitosan-metal ion-ligand composite flocculent gel suspension;

[0045] (3) Preparation of chitosan-ZIF-8 composite gel particles: the chitosan-metal ion-ligand composite flocculent gel suspension obtained in the collection step (2) is transferred to a polytetrafluoroethylene reactor. At 40°...

Embodiment 3

[0048] (1) Prepare chitosan-metal ion solution: weigh 0.2g chitosan powder, fully disperse in 99.8mL deionized water to obtain chitosan powder suspension; add 2mL glacial acetic acid, stir and dissolve to obtain chitosan solution; add 0.8g zinc nitrate hexahydrate again, stir and dissolve fully, obtain chitosan-zinc ion precursor solution;

[0049] (2) Prepare chitosan-metal ion-ligand gel: prepare (10.0%) sodium hydroxide and 2-methylimidazole (5.0%) composite coagulation bath, under 1000r / min stirring effect, to sodium hydroxide Add the chitosan-zinc ion precursor solution dropwise to the 2-methylimidazole composite coagulation bath until the chitosan completely forms a gel to obtain the chitosan-metal ion-ligand composite flocculent gel suspension;

[0050] (3 prepare chitosan-ZIF-8 composite gel particles: the chitosan-metal ion-ligand composite flocculent gel suspension that collection step (2) obtains is transferred in polytetrafluoroethylene reactor, at 60 Under the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com