A construction method for wall anti-alkali

A construction method and wall technology, applied in covering/lining, construction, building components, etc., can solve the problems of house maintenance work, white hair on the wall, ugly wall, etc., so as to avoid wall anti-alkali and simple process , Reduce the effect of post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

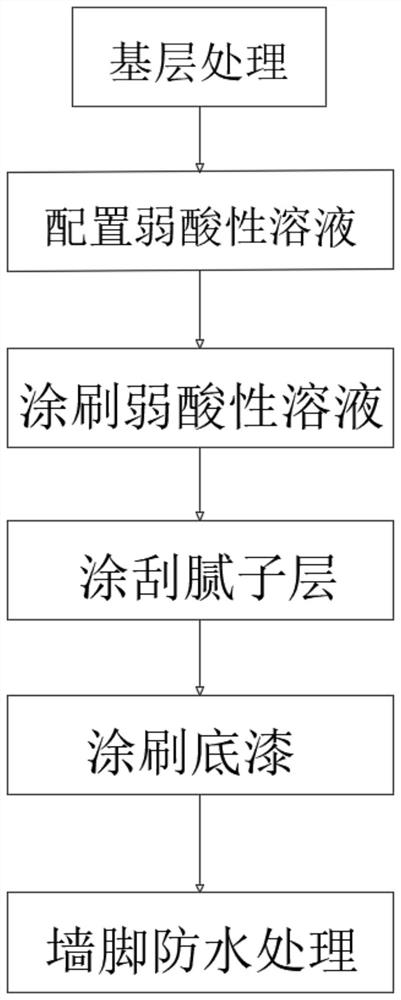

[0041] like figure 1 As shown, the present embodiment provides a construction method for anti-alkali wall, comprising the following steps:

[0042] S1. Basic-level processing; basic-level processing includes the following steps:

[0043] S101. Preparation of moisture-proof materials:

[0044] Take cement and sand at a weight ratio of 1:2.5, add water, mix and stir to make cement mortar, and the amount of water added to prepare cement mortar is common knowledge, so I won’t repeat it here.

[0045] Then take an inorganic aluminum salt waterproofing agent according to 3% of the total weight of the prepared cement mortar, add it into the cement mortar, stir and mix evenly, and obtain a moisture-proof material.

[0046] S102. Take the moisture-proof material and paint it on the wall, and form a moisture-proof layer after natural drying to obtain a moisture-proof wall surface. The thickness of the moisture-proof layer is 20mm, so as to keep the wall surface dry and make the moistu...

Embodiment 2

[0053] like figure 1 As shown, the present embodiment provides a construction method for anti-alkali wall, comprising the following steps:

[0054] S1. Basic-level processing; basic-level processing includes the following steps:

[0055] S101. Preparation of moisture-proof materials:

[0056] Take cement and sand at a weight ratio of 1:2.5, add water, mix and stir to make cement mortar, and the amount of water added to prepare cement mortar is common knowledge, so I won’t repeat it here.

[0057] Then take an inorganic aluminum salt waterproofing agent according to 5% of the total weight of the prepared cement mortar, add it into the cement mortar, stir and mix evenly, and obtain a moisture-proof material.

[0058] S102. Take the moisture-proof material and paint it on the wall, and form a moisture-proof layer after natural drying to obtain a moisture-proof wall surface. The thickness of the moisture-proof layer is 20mm, so as to keep the wall surface dry and make the moistu...

Embodiment 3

[0065] like figure 1 As shown, the present embodiment provides a construction method for anti-alkali wall, comprising the following steps:

[0066] S1. Basic-level processing; basic-level processing includes the following steps:

[0067] S101. Preparation of moisture-proof materials:

[0068] Take cement and sand at a weight ratio of 1:2.5, add water, mix and stir to make cement mortar, and the amount of water added to make cement mortar is common knowledge, so I won’t repeat it here.

[0069] Then take a higher fatty acid waterproofing agent according to 4% of the total weight of the prepared cement mortar, add it into the cement mortar, stir and mix evenly, and obtain a moisture-proof material.

[0070] S102. Take the moisture-proof material and paint it on the wall, and form a moisture-proof layer after natural drying to obtain a moisture-proof wall surface. The thickness of the moisture-proof layer is 20mm, so as to keep the wall surface dry and make the moisture content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com