Pipe truss processing bed-jig and pipe truss manufacturing process

A technology of tube truss and tire frame, which is applied in the field of tube truss processing tire frame and tube truss manufacturing technology, which can solve the problems of inability to connect to another chord, inefficiency, high labor cost, etc., and achieve control tool cost, accurate processing and production, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

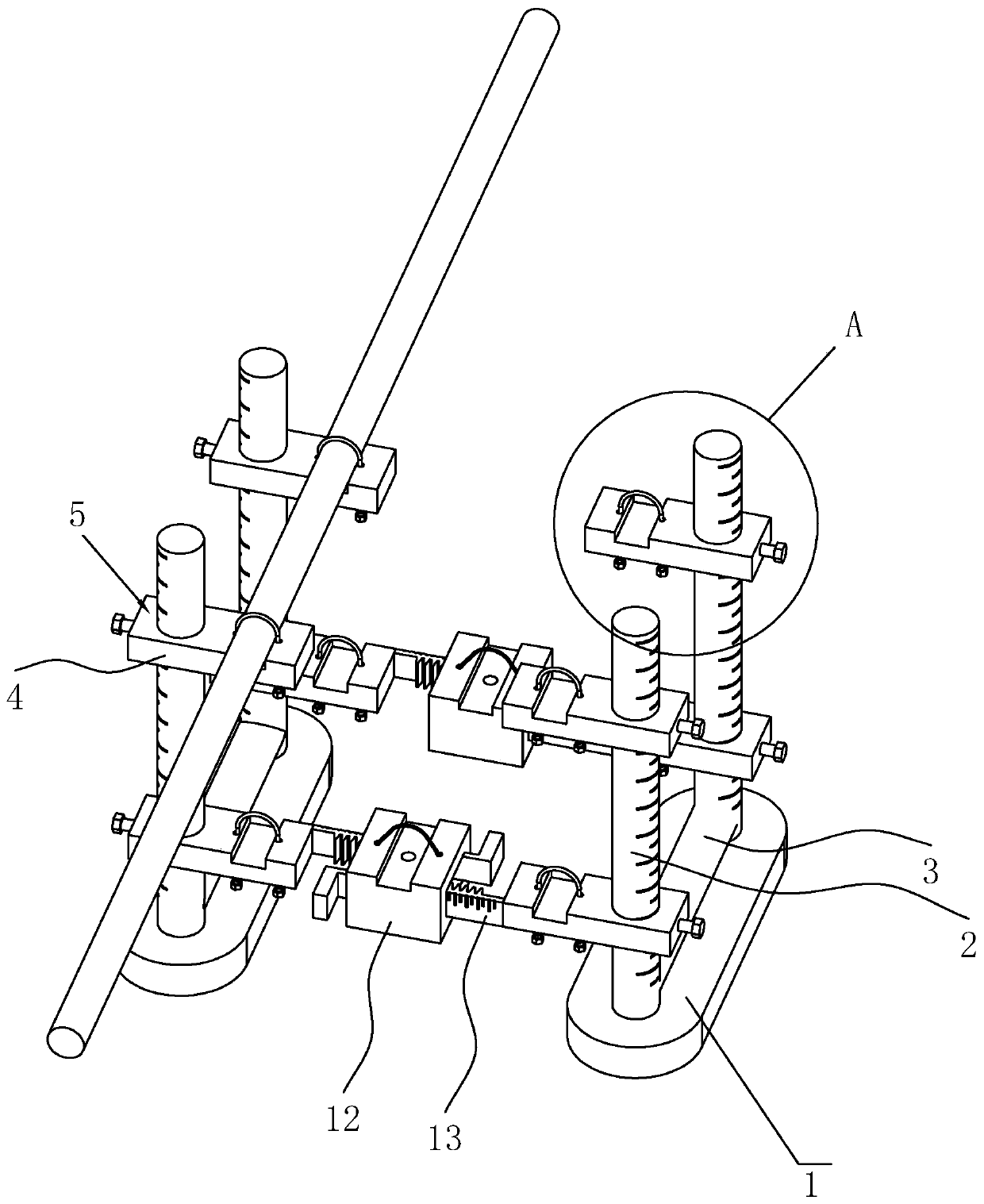

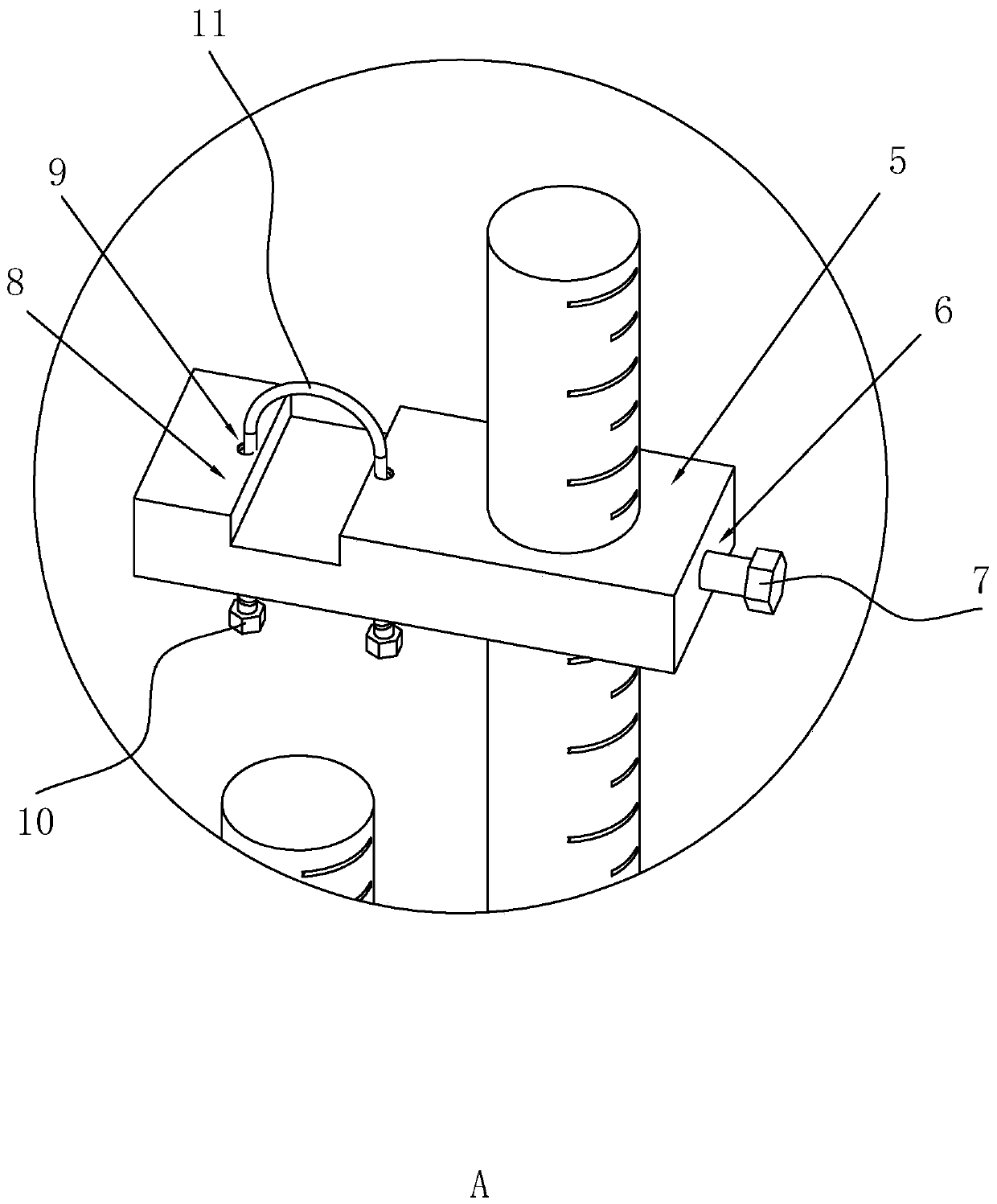

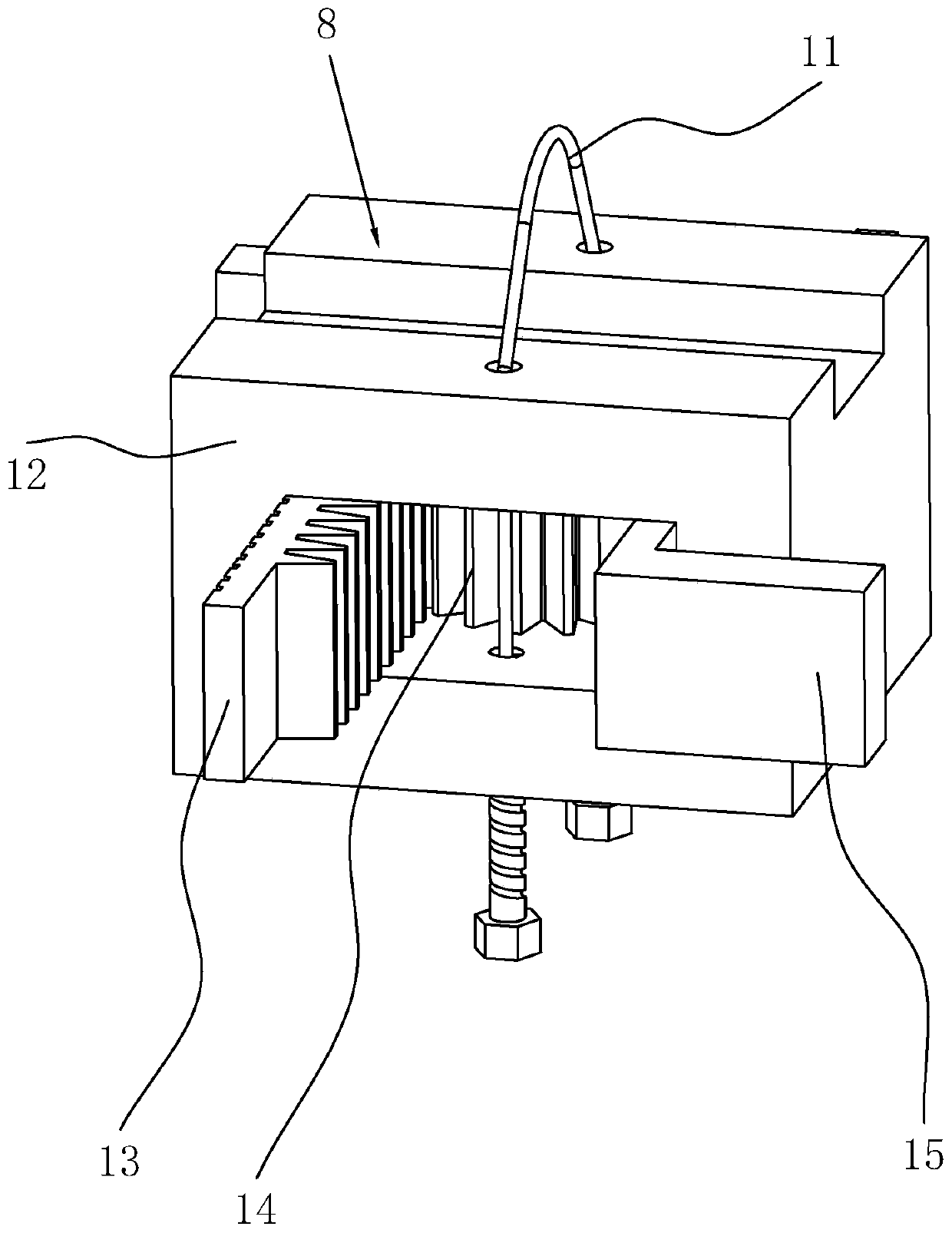

[0040] refer to figure 1 , is a tube truss processing frame disclosed by the present invention, including two sets of chord placing frames 1 for placing chords, and each set of chord placing frames 1 includes multiple sets of vertically arranged installation rods 2, each set of chords There are horizontal connecting rods 3 connected between the bottom ends of multiple groups of mounting rods 2 of the pole placement frame 1, and the arrangement directions of the mounting rods 2 in the two groups of chord placement frames 1 are parallel, and each installation rod in the two groups of chord placement frames 1 The rods 2 are in one-to-one correspondence and the connecting line is perpendicular to the extension direction of the chord placement frame 1 . At the same time, two sets of chord placement plates 4 for placing chords are movable on the installation rod 2, a positioning piece is arranged between the chord placement plate 4 and the installation rod 2, and chord placement pla...

Embodiment 2

[0047] A pipe truss manufacturing process using the pipe truss proposed in Embodiment 1 to process tire frames, comprising the following steps:

[0048] a, prepare the chord;

[0049] b, prepare the floating rod;

[0050] c. A plurality of chords are respectively fixedly installed on each chord placement plate 4 in the pipe truss processing tire frame;

[0051] d. Carry out floating rod welding between two chord rods;

[0052] e. Hoisting transfer pipe truss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com