Performance simulation test device and test method of spiral groove gas dynamic pressure thrust bearing

A technology of thrust bearing and simulation test, which is applied in the direction of mechanical bearing test and wear resistance test, can solve the problems of long test period and high cost, and achieve the effect of start-stop friction performance test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

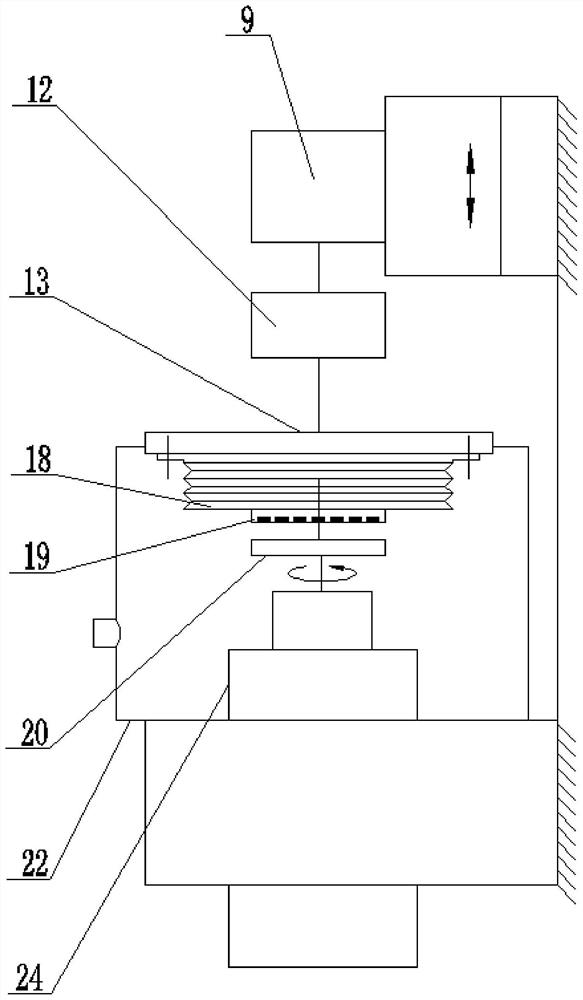

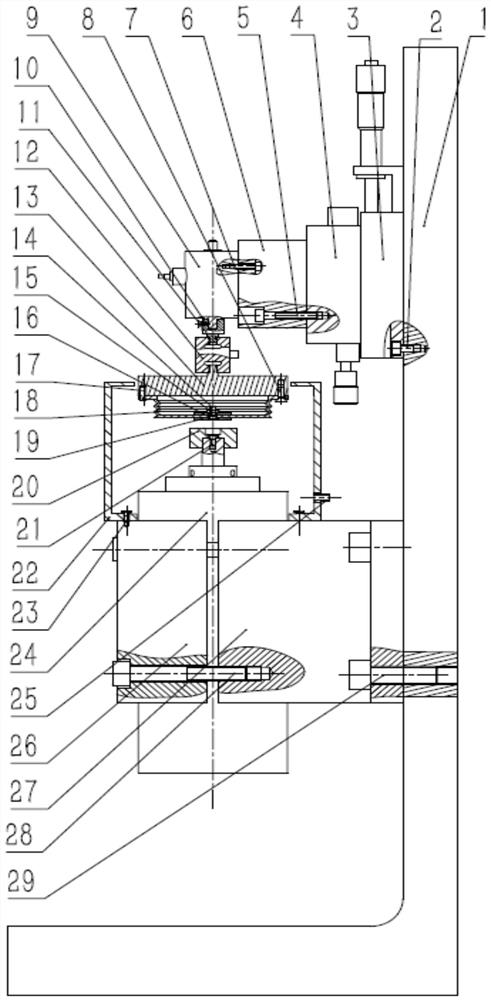

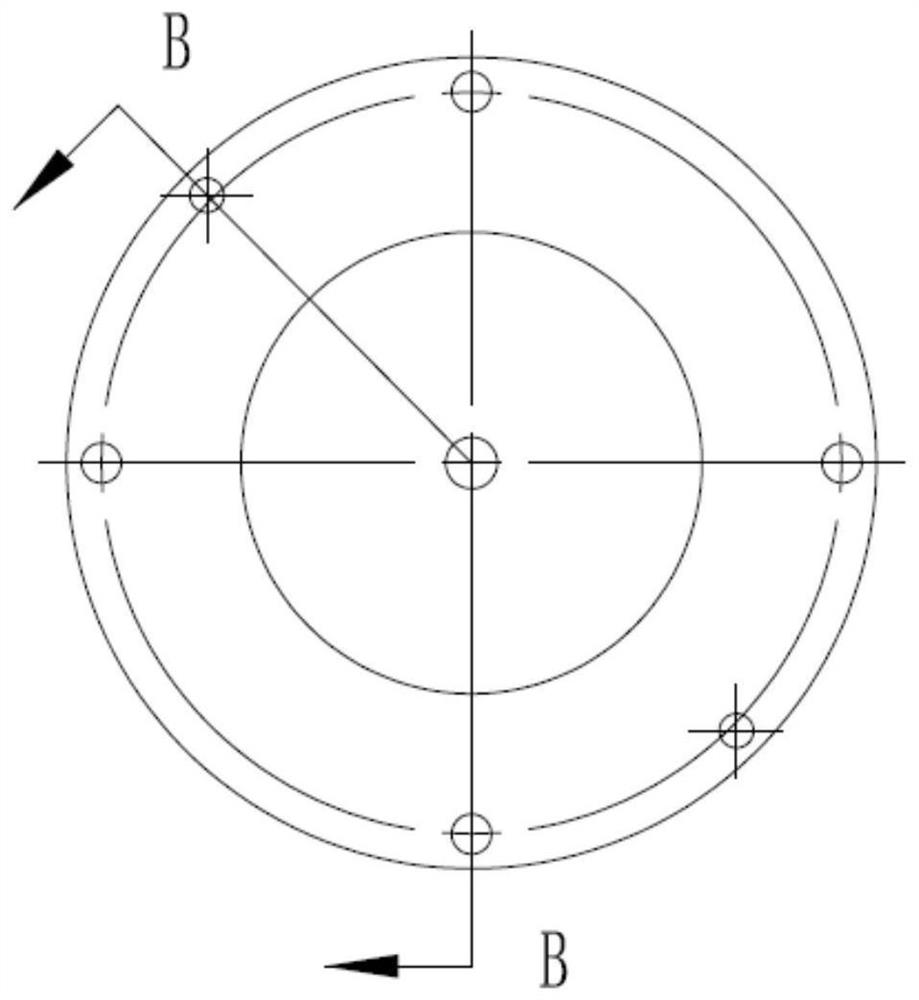

[0026] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the spiral groove gas dynamic pressure thrust bearing performance simulation test device in this embodiment includes a vertical test bench 1, a gas bearing simulation module, a drive module, an atmosphere environment simulation module, a displacement adjustment module, a loading module and Monitoring module; the displacement adjustment module is fixedly installed on the vertical test bench 1, the monitoring module is installed on the displacement adjustment module, the loading module is installed on the monitoring module, and the driving module is installed on the vertical test bench 1 opposite to the loading module , the gas bearing simulation module is installed between the driving module and the loading module, and the atmosphere environment simulation module is installed on the fixed platform of the driving module.

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the spiral groove gas dynamic pressure thrust bearing performance simulation test device in this embodiment, the displacement adjustment module includes a precision translation stage 3, a precision angular displacement stage 4, a torsional transmission support plate 6, a plurality of connecting screws 1 and 2 A plurality of connecting screws 25; the twisted transmission support plate 6 is installed on one end of the precision angular displacement table 4 through a plurality of connecting screws 25, and the other end of the precision angular displacement table 4 is fixedly installed on one end of the precision translation table 3, and the precision translation The other end of the platform 3 is installed on the vertical test platform 1 through a plurality of connecting screws 1-2. Other methods are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the spiral groove gas dynamic pressure thrust bearing performance simulation test device in this embodiment, the monitoring module includes a torque sensor 9, a fixing screw 10, a connector 11, a tension pressure sensor 12 and a plurality of connecting screws 3 7; The torque sensor 9 is installed on the twisting support plate 6 through a plurality of connecting screws 37, one end of the connecting piece 11 is fixedly connected with the torque sensor 9 through the fixing screw 10, and the other end of the connecting piece 11 is fixed with one end of the tension pressure sensor 12 Connection, the other end of the tension pressure sensor 12 is fixedly connected to the loading module, and other methods are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com