Manufacturing method of 5G signal shielding PCB module with latches

A technology of signal shielding and production methods, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as difficult to guarantee the quality of mass production, and achieve the effects of fast delivery, cost reduction, and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

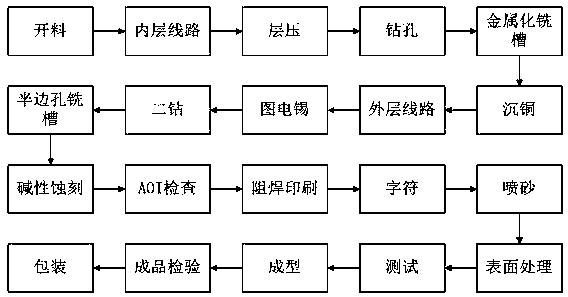

[0034] A method for manufacturing a 5G signal shielding PCB module with locking teeth, comprising the following steps:

[0035] S1. Main process: In the main process, when the AOI inspection is performed on the line after the outer layer is etched, in addition to the routine inspection, the inspection of copper particles and pinholes is added to ensure that the product has no pinholes and voids, so that the product has a good signal shielding function ;

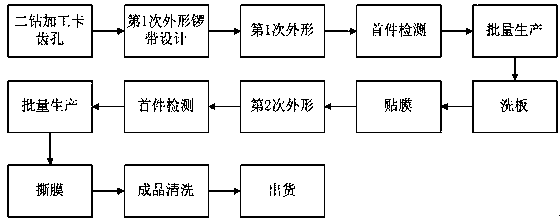

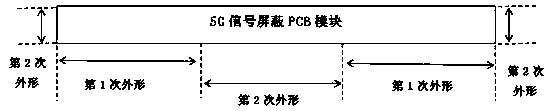

[0036] S2. Forming processing sub-process: Half hole milling and metallization milling must be done according to the expansion and contraction of the drilling file to ensure the shape and accuracy of the slot; Necessary conditions for the final processing accuracy of products without internal positioning to be qualified;

[0037] S3. Clamp tooth size processing: the diameter of the half hole at the root of both sides of the clamp tooth is 0.1-1mm, use the second dimension to test the expansion and contraction of the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com