An ultra-thin paper diaper core and its manufacturing process

A diaper and ultra-thin technology, which is applied in the field of disposable sanitary products, can solve the problems of composite absorbent paper such as low softness, slow absorption speed, and low effective utilization rate of polymers, so as to improve the effective utilization rate and absorption efficiency , the effect of reducing the loss of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

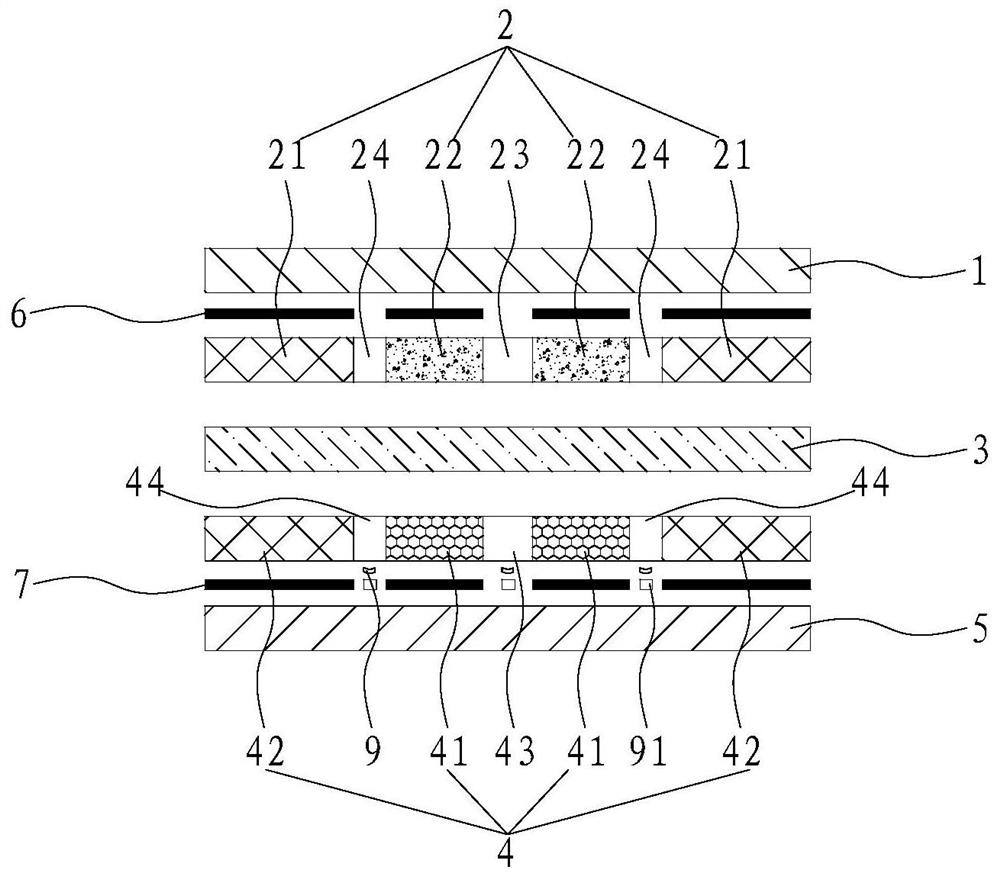

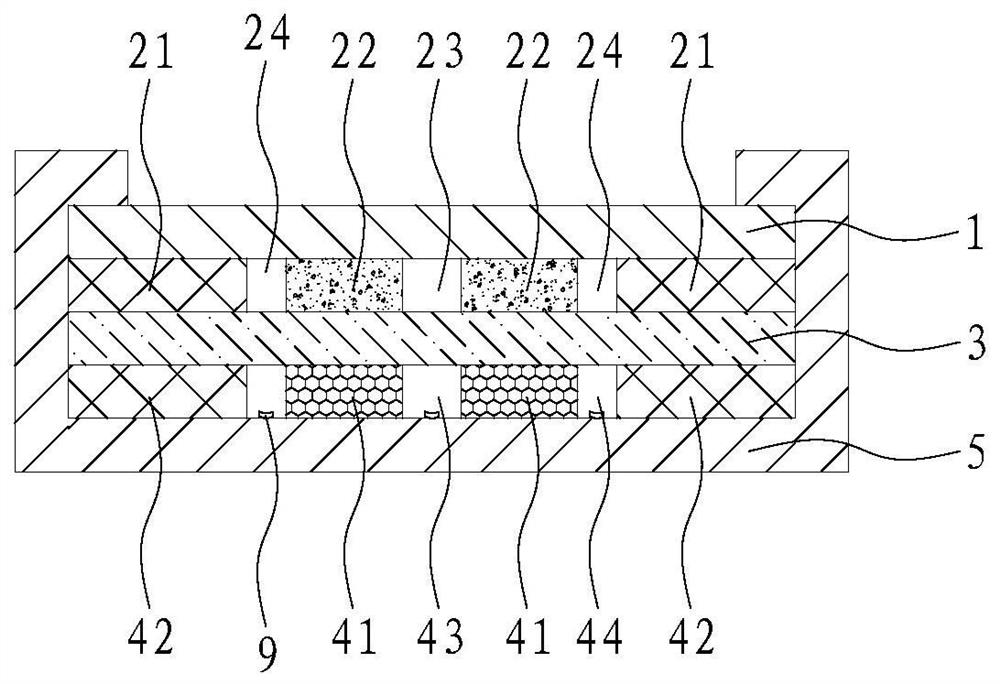

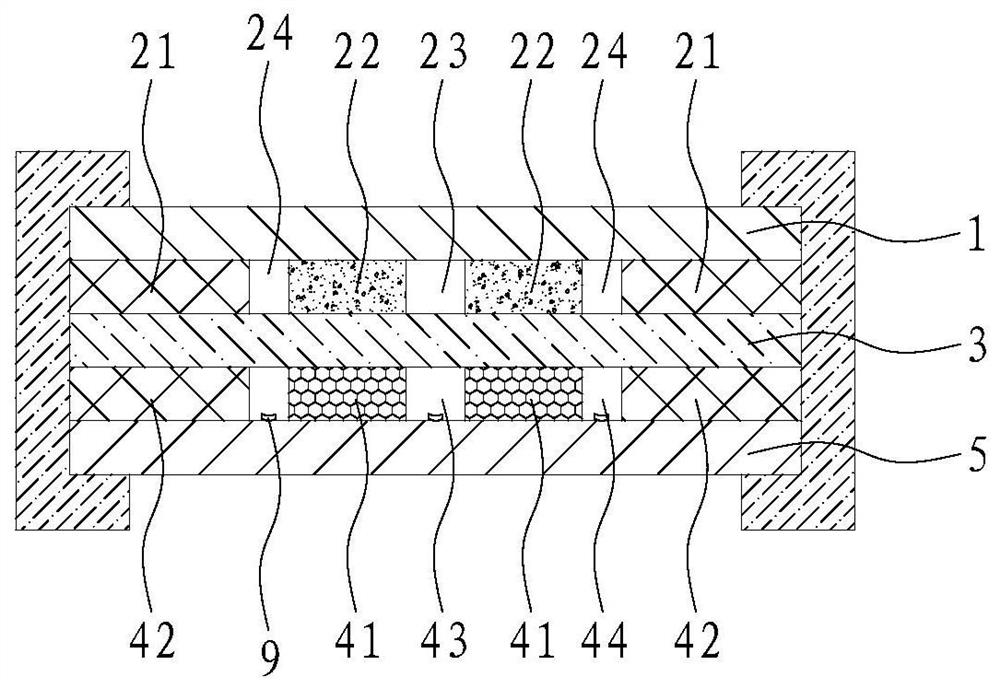

[0036] refer to figure 1 , Figure 4 , Figure 5 , this embodiment provides an ultra-thin diaper core body, including a body, and the body includes a wood pulp spunlace cloth 1, an absorbent upper layer 2, a fluffy non-woven fabric 3, an absorbent lower layer 4, and a viscose spunlace cloth 5 , the absorbent upper layer 2 includes two second SAP layers 22 arranged in the middle, a first SAP layer 21 arranged outside the two second SAP layers 22, a first gap 23 is arranged between the two second SAP layers 22, A second gap 24 is provided between each first SAP layer 21 and the adjacent second SAP layer 22, and the lower absorbent layer 4 includes two third SAP layers 41 located in the middle, and two third SAP layers 41 located between the two third SAP layers 41. For the fourth SAP layer 42 on the outside, a third gap 43 is provided between the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com